Erecting equipment remote actual time safety monitoring system and its control method

A lifting equipment and monitoring system technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of lifting equipment that cannot be remotely monitored in real time, low accuracy, and complicated and difficult human supervision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

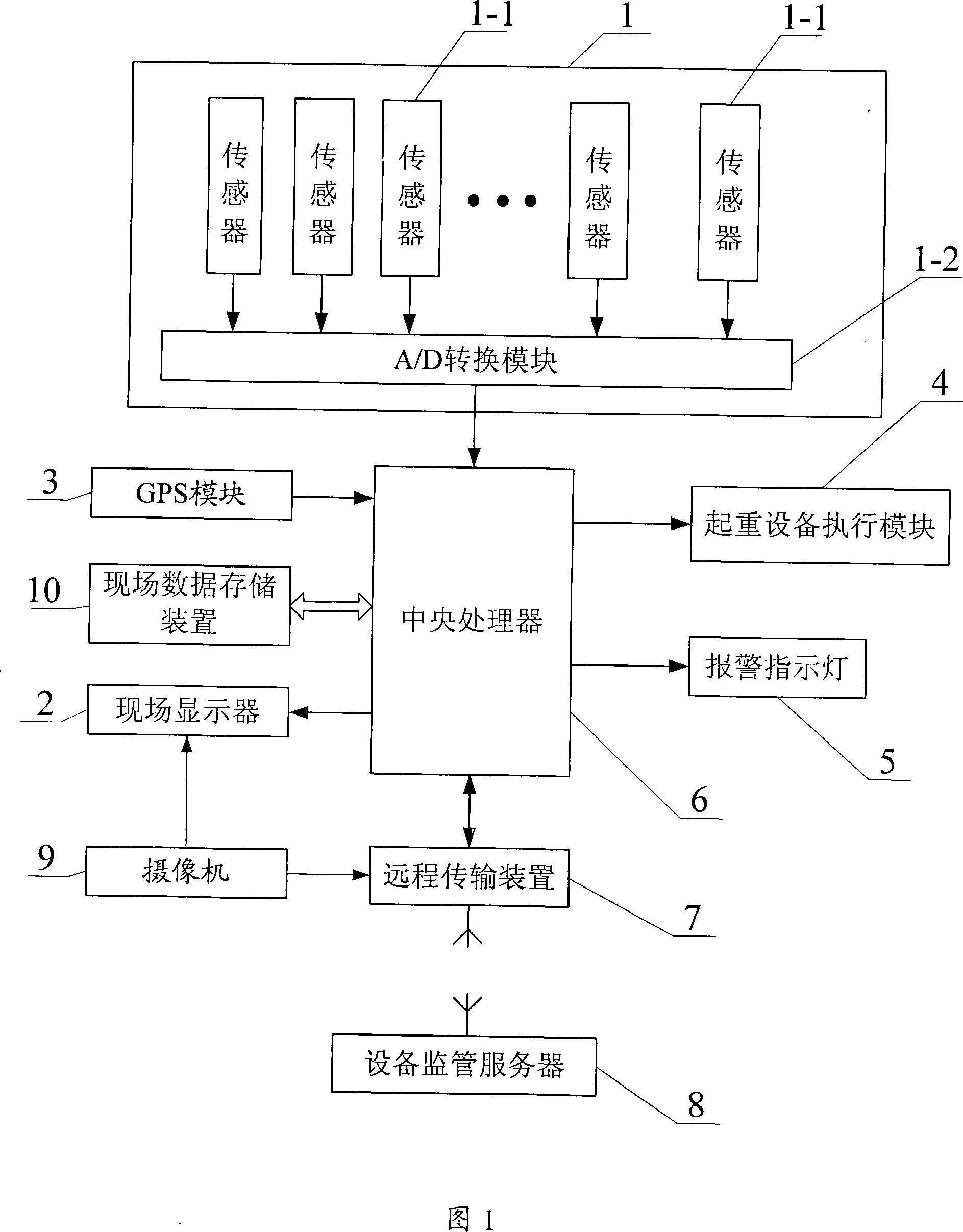

[0038] Embodiment 1: As shown in FIG. 1 , the supervisory system of this specific embodiment includes a sensing signal acquisition device 1 for detecting various parameter information of the lifting equipment, a central processing unit 6, a lifting equipment execution module 4, and a remote transmission device 7. Equipment supervision server 8, on-site display 2, on-site data storage device 10 and alarm indicator light 5; a plurality of signal output ends of the sensing signal acquisition device 1 are respectively connected to a plurality of sensing signals of the central processing unit 6 Input terminal; the lifting equipment execution signal output end of the central processing unit 6 is connected to the input end of the lifting equipment execution module 4, and the lifting equipment execution module 4 receives the lifting equipment execution of the central processing unit 6 The signal is used to control the action of the lifting equipment; the data transmission end of the re...

Embodiment 2

[0042] Embodiment two: as shown in Figure 1, on the basis of embodiment one: the supervisory system also includes a camera 9, the video information output end of the camera is respectively connected to the image data of the on-site display and the remote transmission device input. By adopting the specific implementation mode, it is convenient for the operator to obtain the actual operating conditions on the boom of the crane more intuitively, and to control the lifting equipment more effectively. For example, as shown in Figure 6, a 27-fold automatic integrated auto-focus camera can be used on the tower crane, and installed under the luffing trolley of the tower crane, aligned with the hook, to monitor the hoisting situation of the tower crane at all times . Due to the frequent movement of the luffing trolley, a special set of video cable connection device is required. As shown in Figure 6, the lower chord 11 is a square steel pipe, and the root and front end of the jib are ...

Embodiment 3

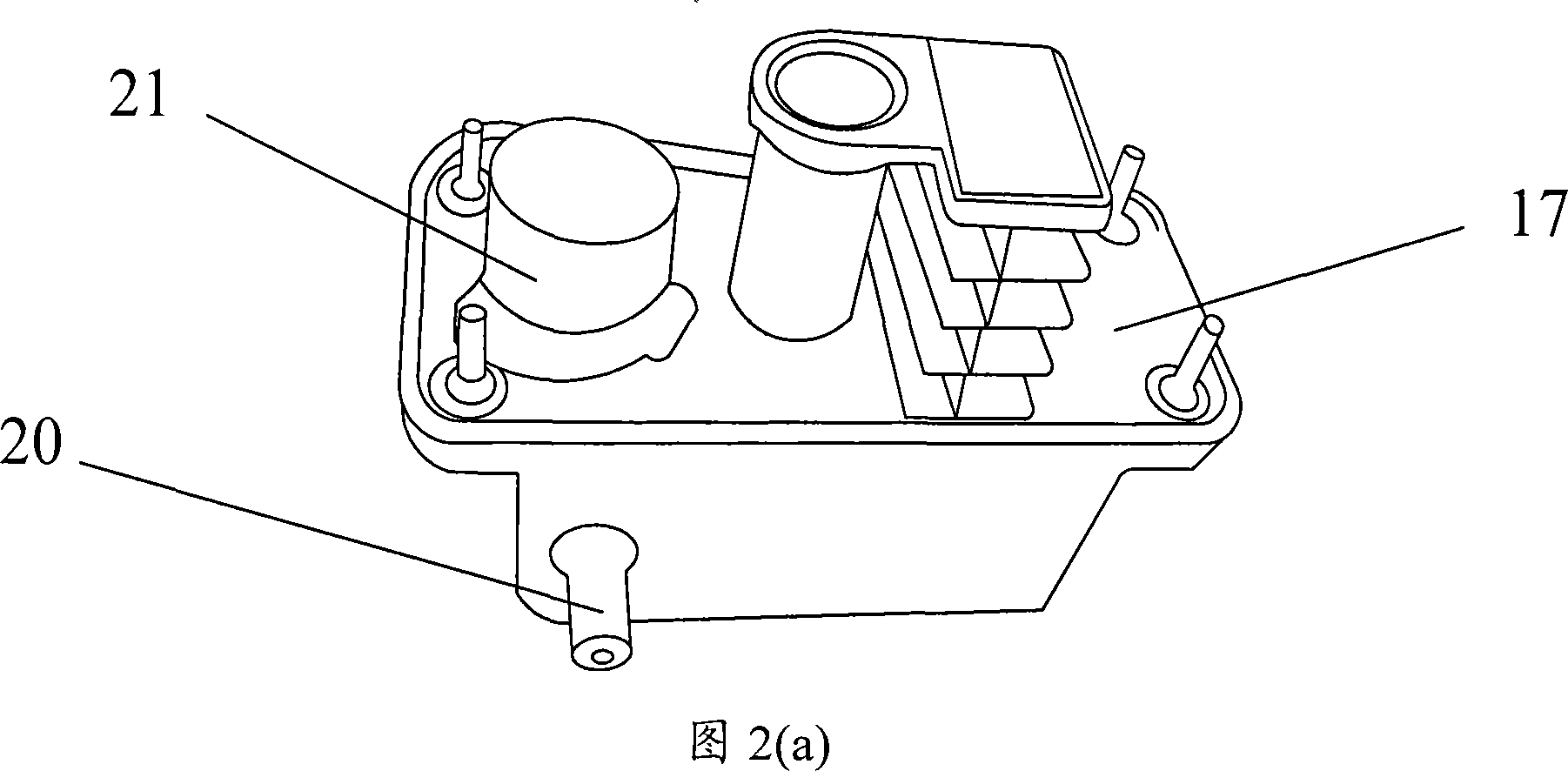

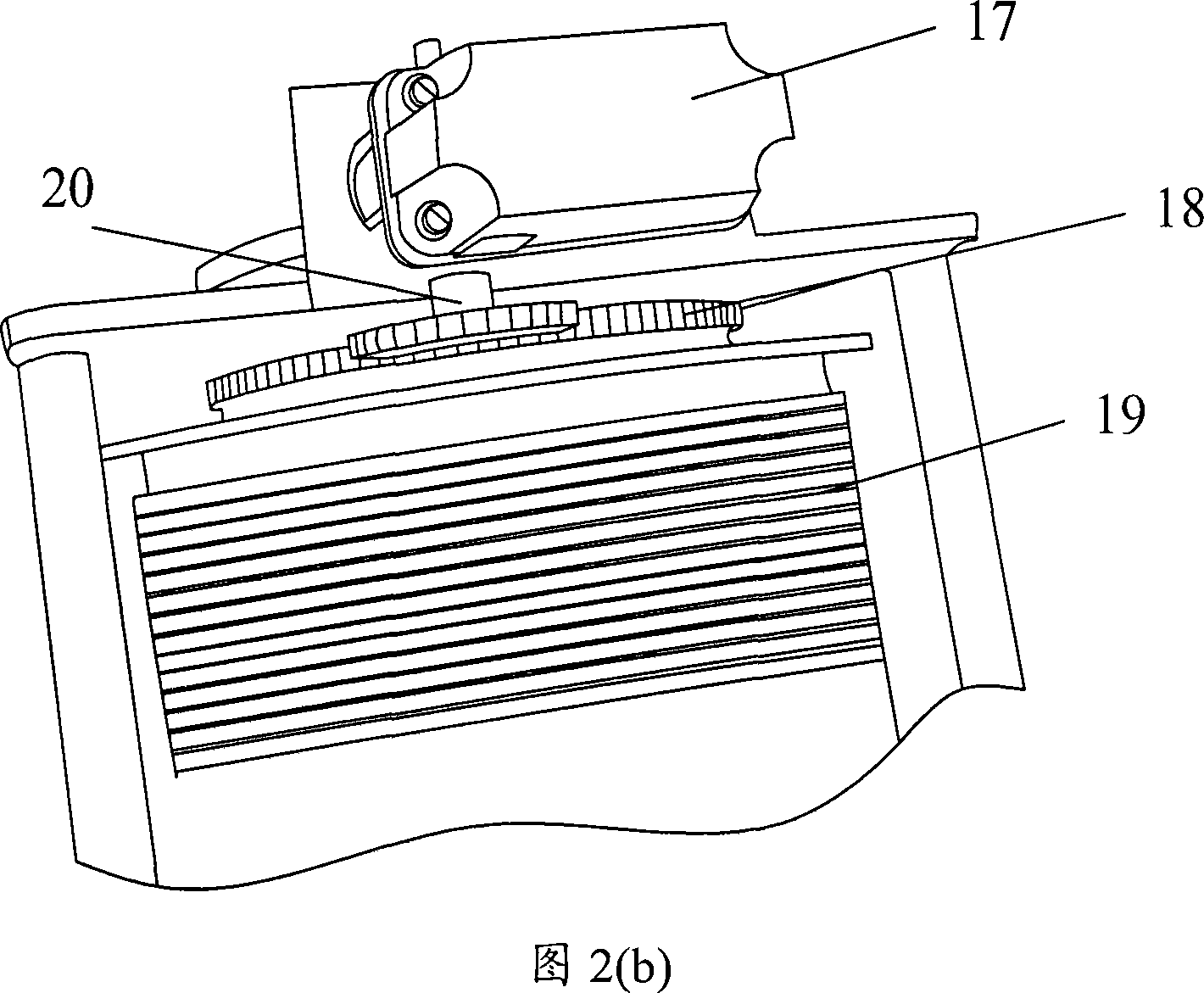

[0043] Embodiment 3: As shown in FIG. 1 , on the basis of Embodiment 1: the sensing signal acquisition device 1 includes a plurality of sensors 1-1 and A / D conversion modules 1-2, and the plurality of sensors 1 -1 The parameter signals measured respectively are processed by the A / D conversion module 1-2 and sent to the central processing unit 6 . The plurality of sensors 1-1 includes a plastic potentiometer, which is installed in the stroke limiting device of the lifting equipment, and the signal input end of the plastic potentiometer is connected to the detection signal input end of the stroke limiting device . The plastic potentiometer is used to measure the height and range of the lifting equipment in real time; if the lifting equipment uses a multi-function limiter to limit the height and range, the plastic potentiometer can be installed inside the multi-function limiter , the plastic potentiometer can be a potentiometer with a model number of WDD35D-4. As shown in Fig. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com