Hybrid power plant for engineering machinery

A technology of hybrid power and power device, which can be used in the field of fuel oil, hydraulic excavators and loaders, and can solve the problems of environmental pollution, inconvenient walking and high cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

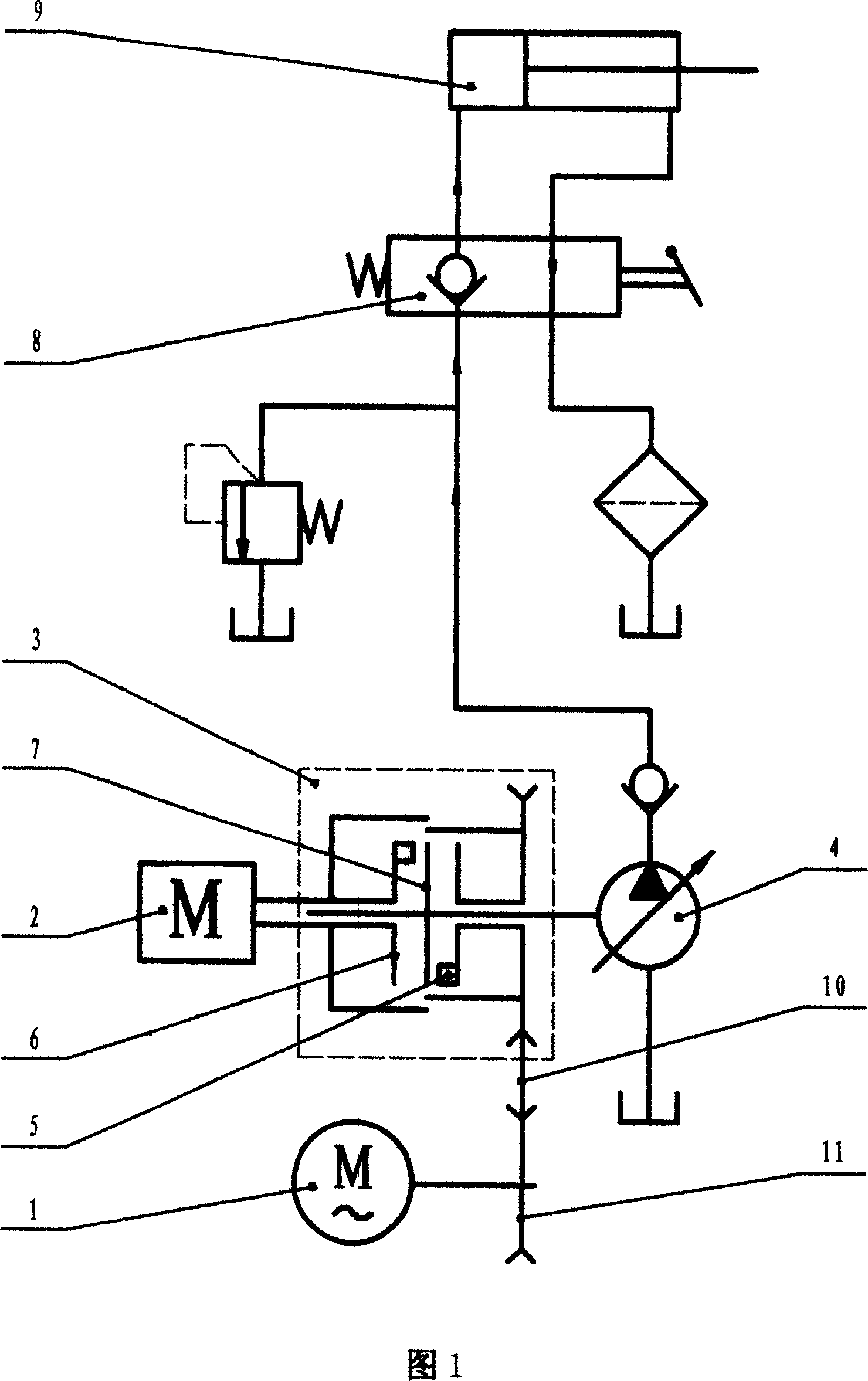

Embodiment 1

[0013] Embodiment 1: As shown in Figure 1, this example is two sets of power equipments driving a hydraulic oil pump, and these two sets of power equipments refer to electric motor (1) and diesel engine (2). The diesel engine (2) is connected to the driving disc (6) of the clutch, and the electric motor (1) is connected to the driving disc (5) of the clutch through a transmission mechanism. The transmission mechanism in this example is a belt drive, and the driving pulley (11) is mounted on the motor shaft Above, the driven pulley and the driving disc (5) of the clutch are an integral body, and the two wheels are connected by a transmission belt (10), and the driven disc (7) of the clutch is connected by a clutch shaft and a hydraulic oil pump.

[0014] When the construction machinery is working on the construction site, it basically becomes a fixed operation equipment. When it is connected to the power supply, the working equipment is driven by the electric motor to work, and ...

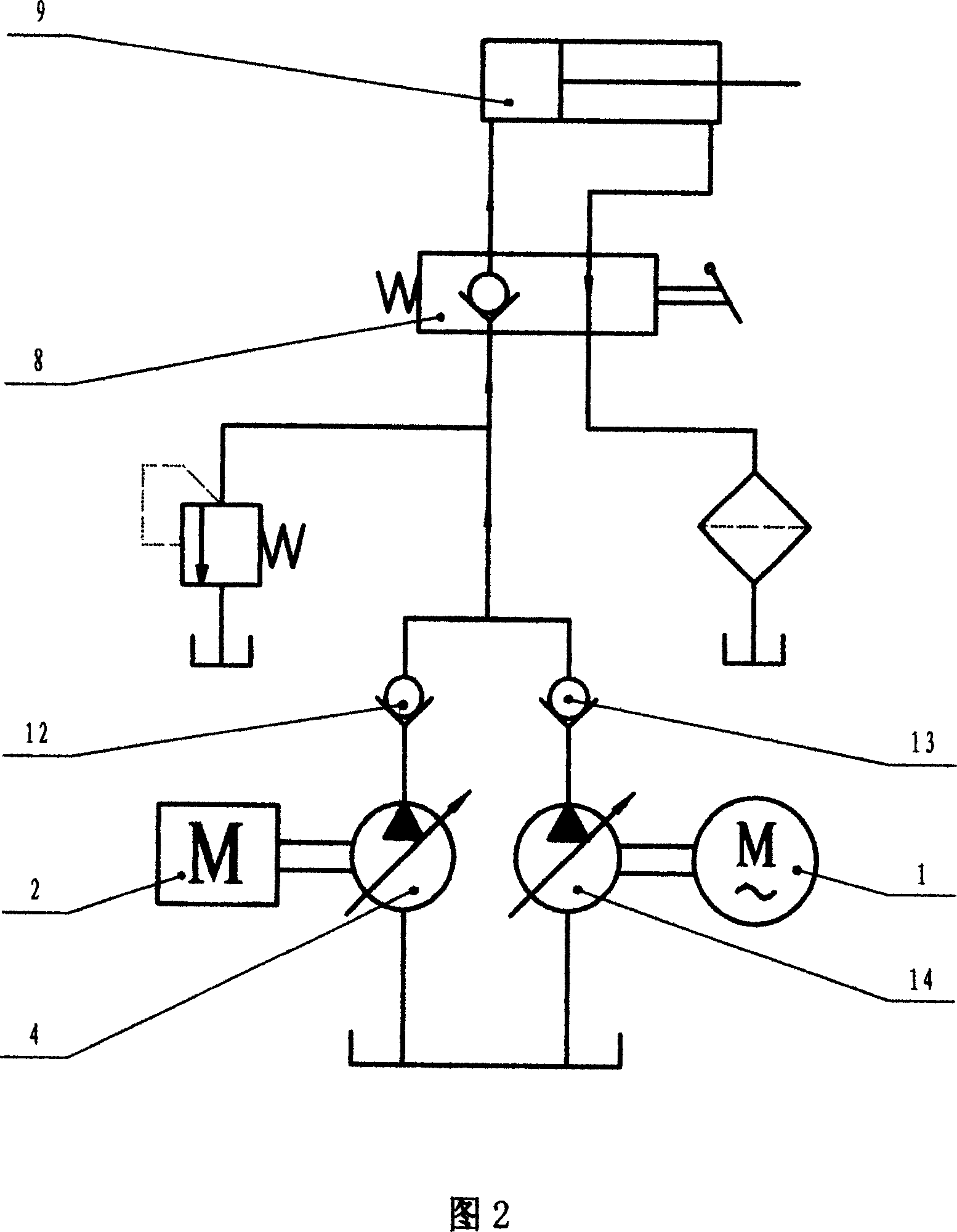

Embodiment 2

[0016] Embodiment 2: As shown in Figure 2, the electric motor (1) and the diesel engine (2) drive two hydraulic oil pumps (14) and (4) respectively, no clutch is needed to switch between the two sets of power, and the diesel engine drives the hydraulic oil pump (4), the electric motor drives the hydraulic oil pump (14), and the two oil pumps are connected in parallel. After being isolated by the check valves (12) and (13), they do not interfere with each other, and then enter the hydraulic oil cylinder ( 9), drag the work tool to work. The parallel connection mentioned here is just a parallel connection. It does not mean that the diesel engine and the electric motor work at the same time, but that one of them is selected to work according to the situation, and the other does not need to work.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com