U-shape tube type heat exchanger

A heat exchanger and U-shaped tube technology, applied in the field of heat exchangers, can solve the problems of high manufacturing cost, low heat exchange efficiency, complicated structure of the heat exchanger, etc., to save manufacturing cost, enhance heat exchange, and improve emission performance The effect of the indicator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

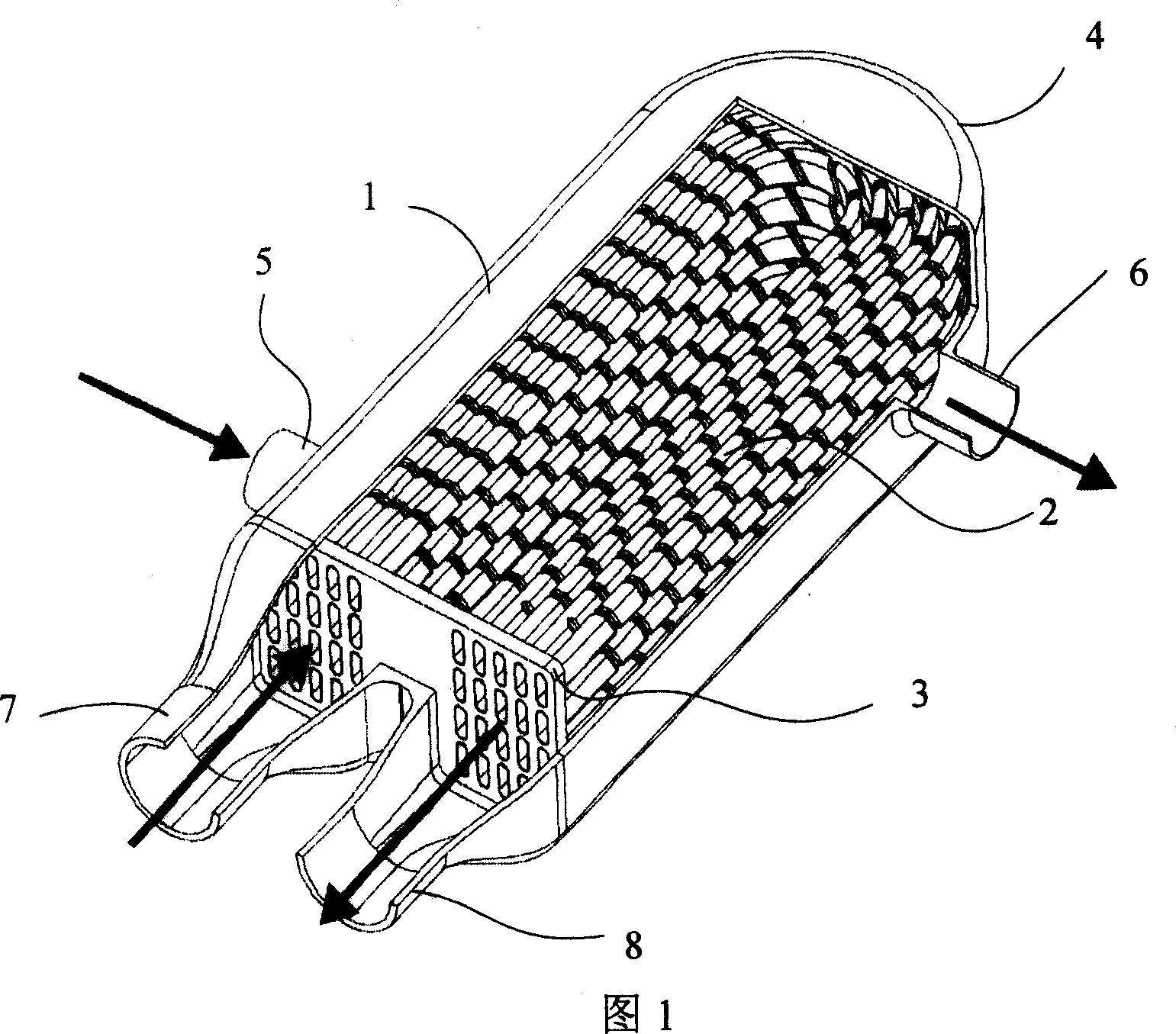

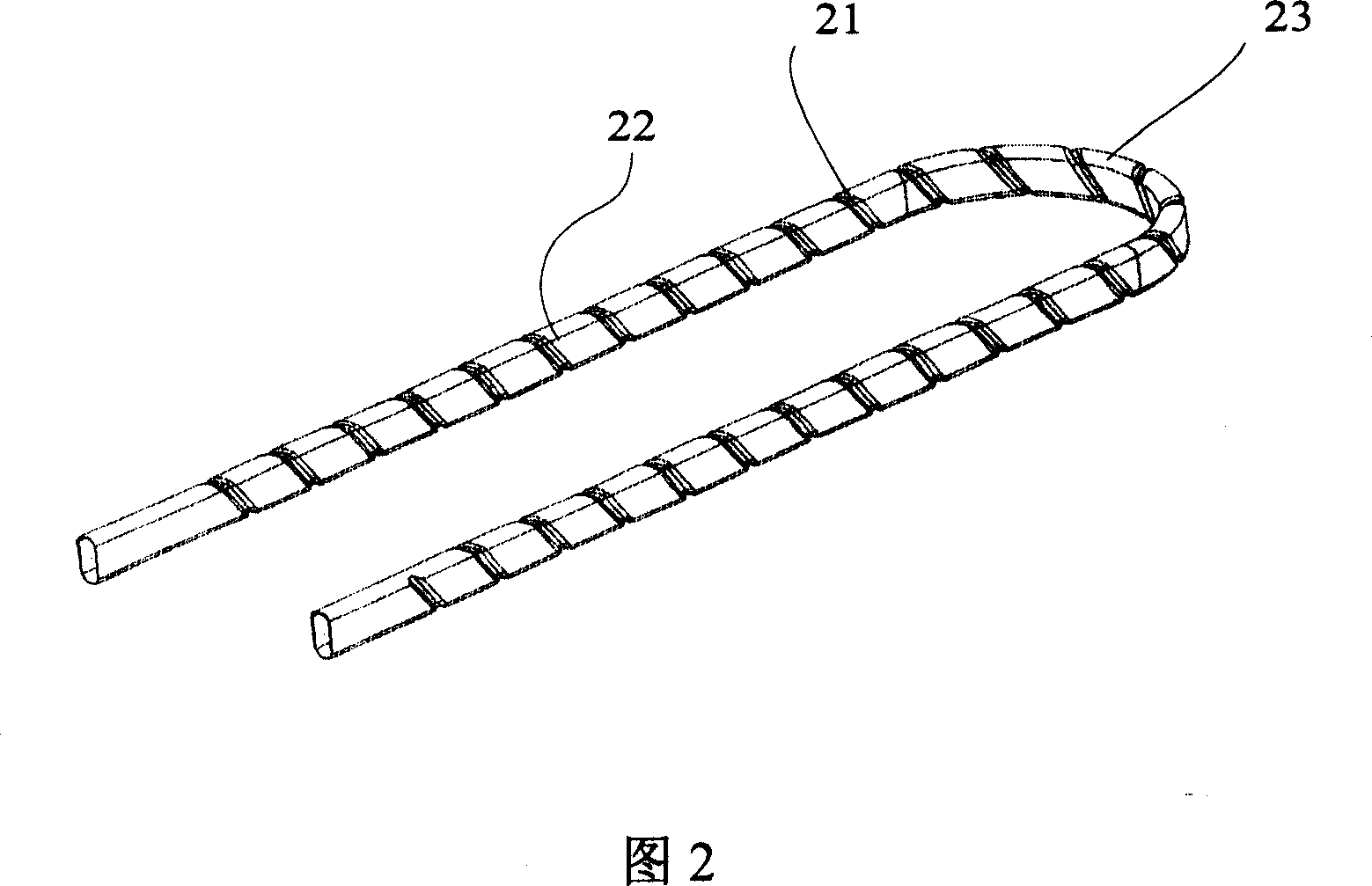

[0038] Referring to Fig. 1 and Fig. 2, an opening is provided at one end of the shell 1, and a tube plate 3 is provided at the opening, the side of the tube plate 3 facing the shell is the inner side, and the two ends of the outer sides of the tube plate 3 are respectively connected with exhaust gas inlets The connection between the pipe 7 and the exhaust gas outlet pipe 8, the inlet pipe 7 and the outlet pipe 8 and the tube plate 3 is trumpet-shaped; there is a fixed U-shaped heat exchange tube on the end surface of the inlet pipe 7 and the outlet pipe 8 of the tube plate 3 2; the heat exchange tube 2 is composed of two equal-length straight pipe sections 22 and a curved section 23 smoothly connected, and the shape is U-shaped; the two nozzles on the U-shaped heat exchange tube 2 are respectively welded on the corresponding The through holes on the corresponding tube sheets 3 are fixed in the shell 1 parallel to each other; the cooling medium inlet 5 is provided on the shell 1...

Embodiment 2

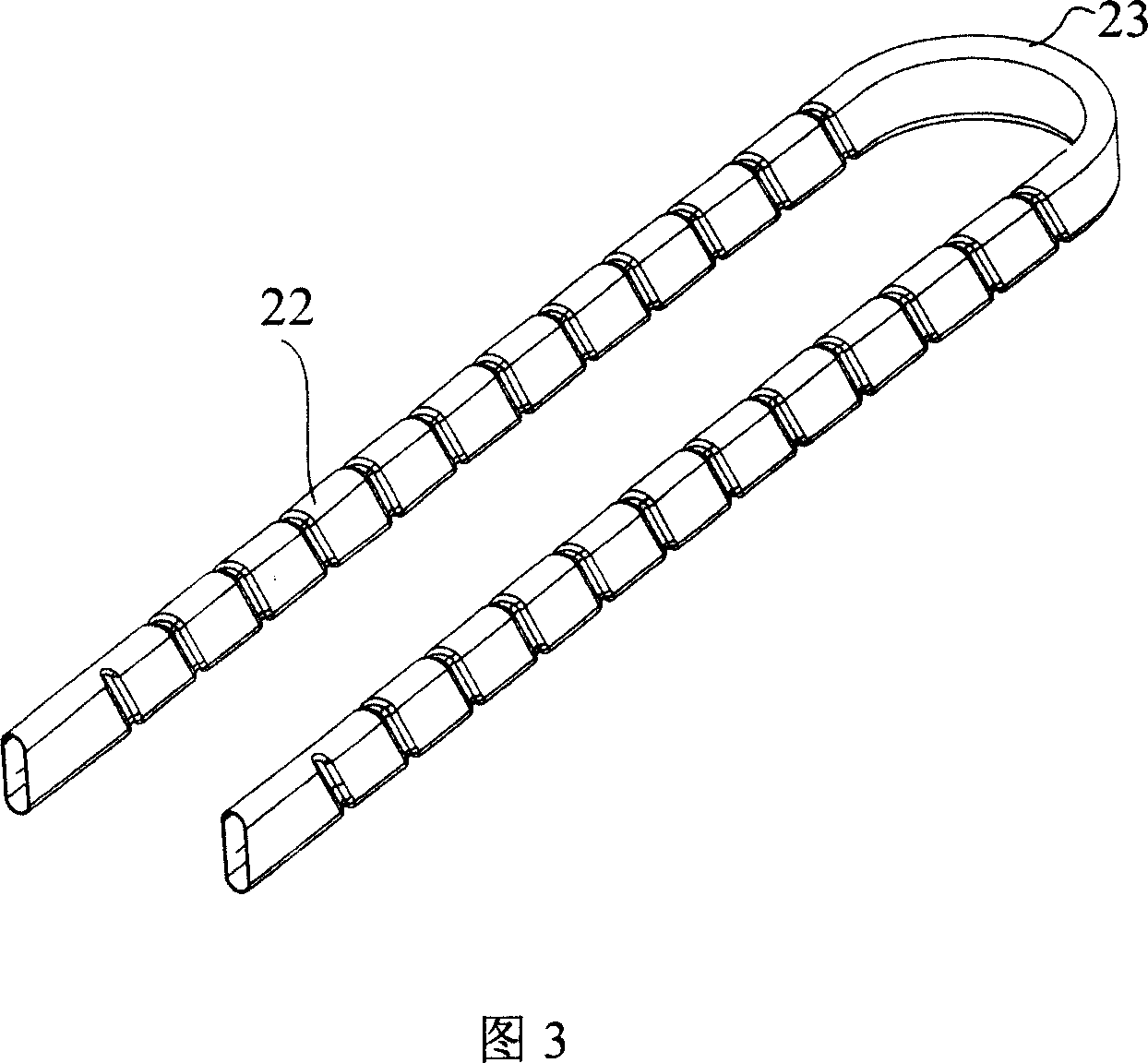

[0042] Referring to FIG. 1 and FIG. 3 , in order to reduce processing difficulty, no spiral groove is provided at the bending section 23 of the U-shaped heat exchange tube 2 fixed in the housing 1 .

[0043] Referring to Fig. 4 to Fig. 8, the vertical section of the U-shaped heat exchange tube 2 fixed in the housing 1 can have various shapes.

[0044]The heat exchange tubes arranged in the shell 1 with a flat cross-sectional shape and spiral grooves are compared with the circular heat exchange tubes with spiral grooves in the cross-sectional shape: First, when the cross-sectional area of the heat exchange tubes is constant and the flow rate of the heat exchange medium is not Under the premise of changing, the cross-sectional perimeter of the flat tube is larger than that of the round tube, so the heat transfer area of the flat tube is larger than that of the round tube, which in turn increases the heat transfer area of the entire heat exchanger. Under the premise that th...

Embodiment 3

[0046] Referring to Fig. 1 and Fig. 4, the U-shaped heat exchange tube 2 fixed in the housing 1 is a U-shaped heat exchange tube 2 with the first cross-sectional shape shown in Fig. 4, and the cross-section of the U-shaped heat exchange tube 2 is flat. The two relatively long sides 25 are straight lines, and the two opposite short sides 24 are arc-shaped protrusions from the inside to the outside, and are connected with the long sides 25 in an arc-shaped transition. Such a setting makes full use of the surface of the heat exchange tube to achieve Maximum efficiency of heat exchange, and easy production and processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com