Light emitting device and method of manufacturing the same

A technology for a light-emitting device and a manufacturing method, which is applied to the manufacturing of semiconductor/solid-state devices, electrical components, and electrical solid-state devices, etc., can solve problems such as difficulty in long-term use, complicated manufacturing processes, and difficult light reflection, and achieve simple manufacturing processes. simplification, process simplification, and good reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

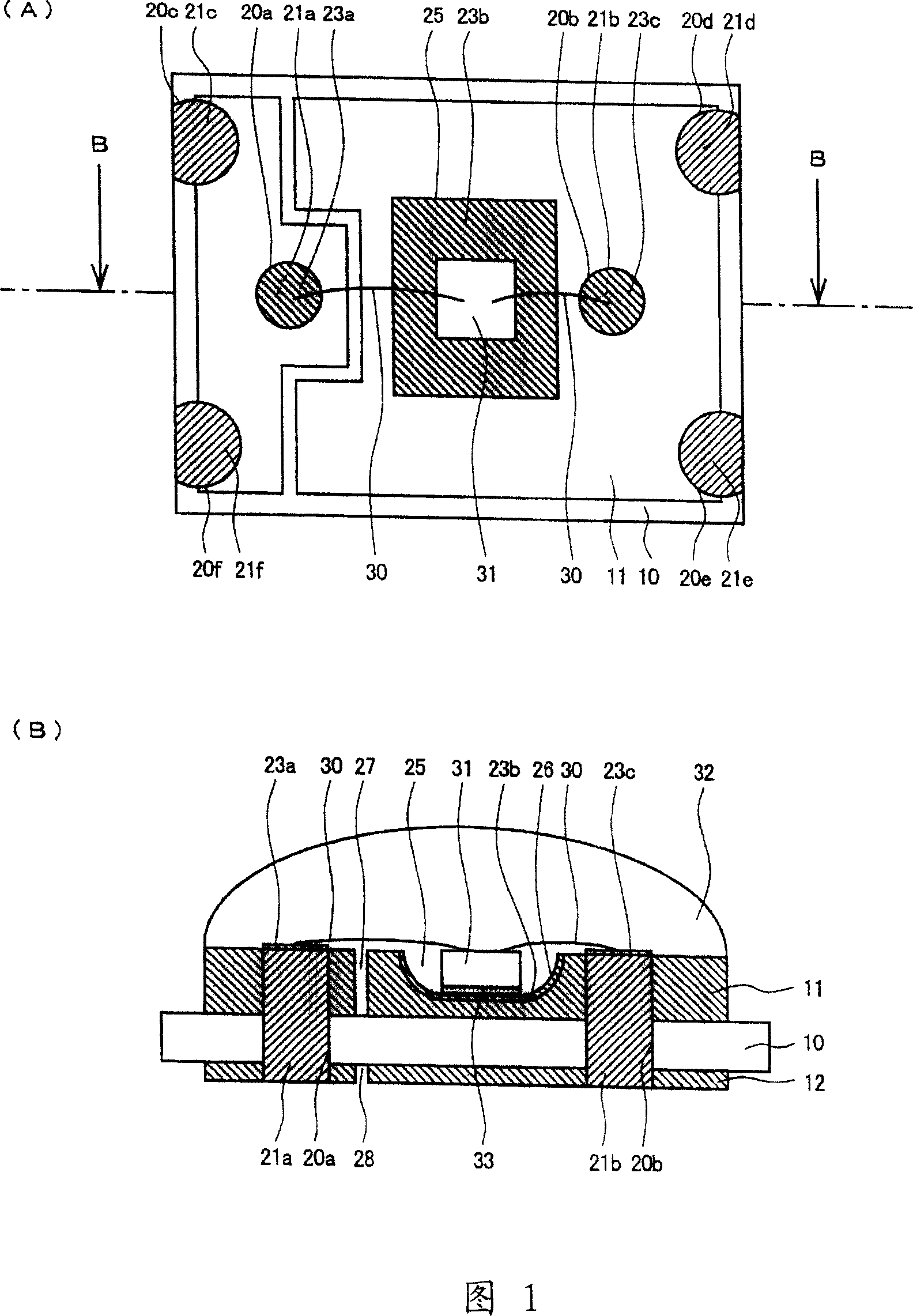

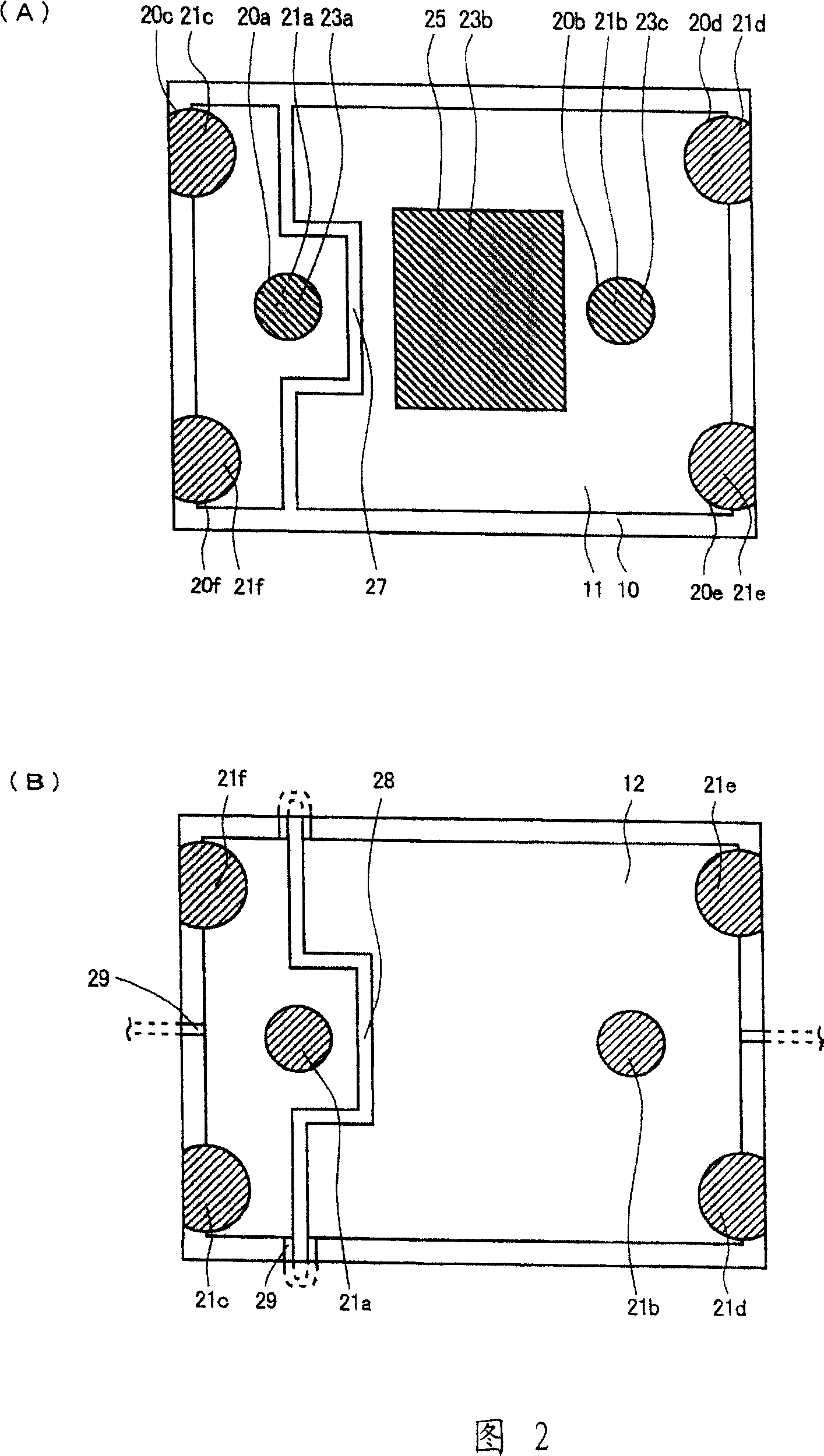

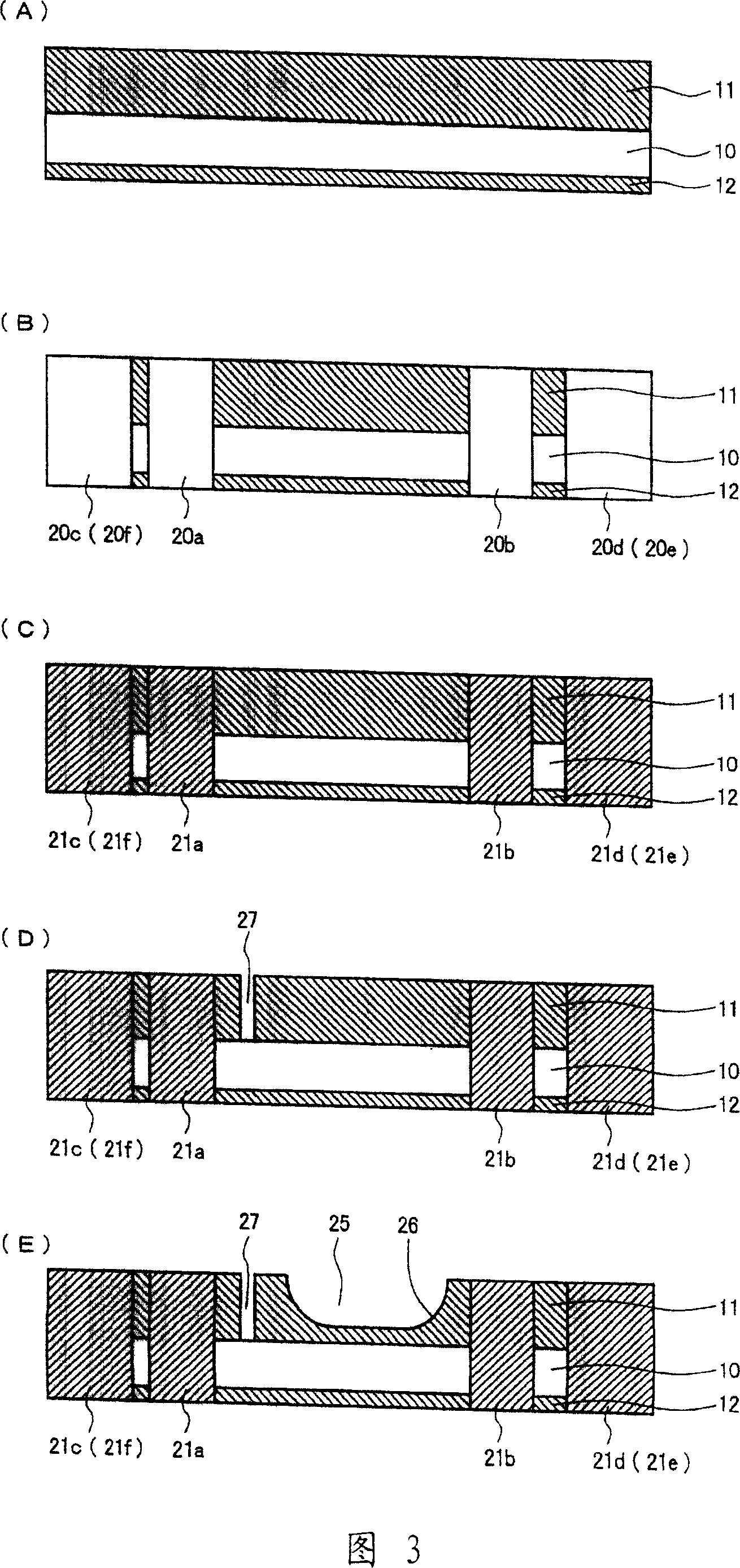

[0048] First, FIG. 1 shows a light emitting device of the present invention. FIG. 1(A) is a top view thereof, and FIG. 1(B) is a cross-sectional view thereof.

[0049] The light-emitting device of the present invention includes: an insulating substrate 10, a thick first conductive foil 11 arranged on one main surface of the insulating substrate 10, a thin second conductive foil 12 arranged on the opposite main surface of the insulating substrate 10, and a thin second conductive foil 12 arranged on the second main surface of the insulating substrate 10. A half-etched hole 25 on a conductive foil 11, a light emitting element 31, through-hole electrodes 21a, 21b, 21c, 21d, 21e, 21f connecting the first conductive foil 11 and the second conductive foil 12, conductive metal layers 23a, 23b , 23c, thin metal wire 30 and transparent protective resin 32.

[0050] It is preferable to use a glass epoxy substrate or a glass polyimide substrate as the insulating substrate 10 . It functi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com