Excimer lamp

An excimer lamp and excimer technology, which is applied in the field of excimer lamps and can solve problems such as peeling off of the end of the ultraviolet reflective film 104

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

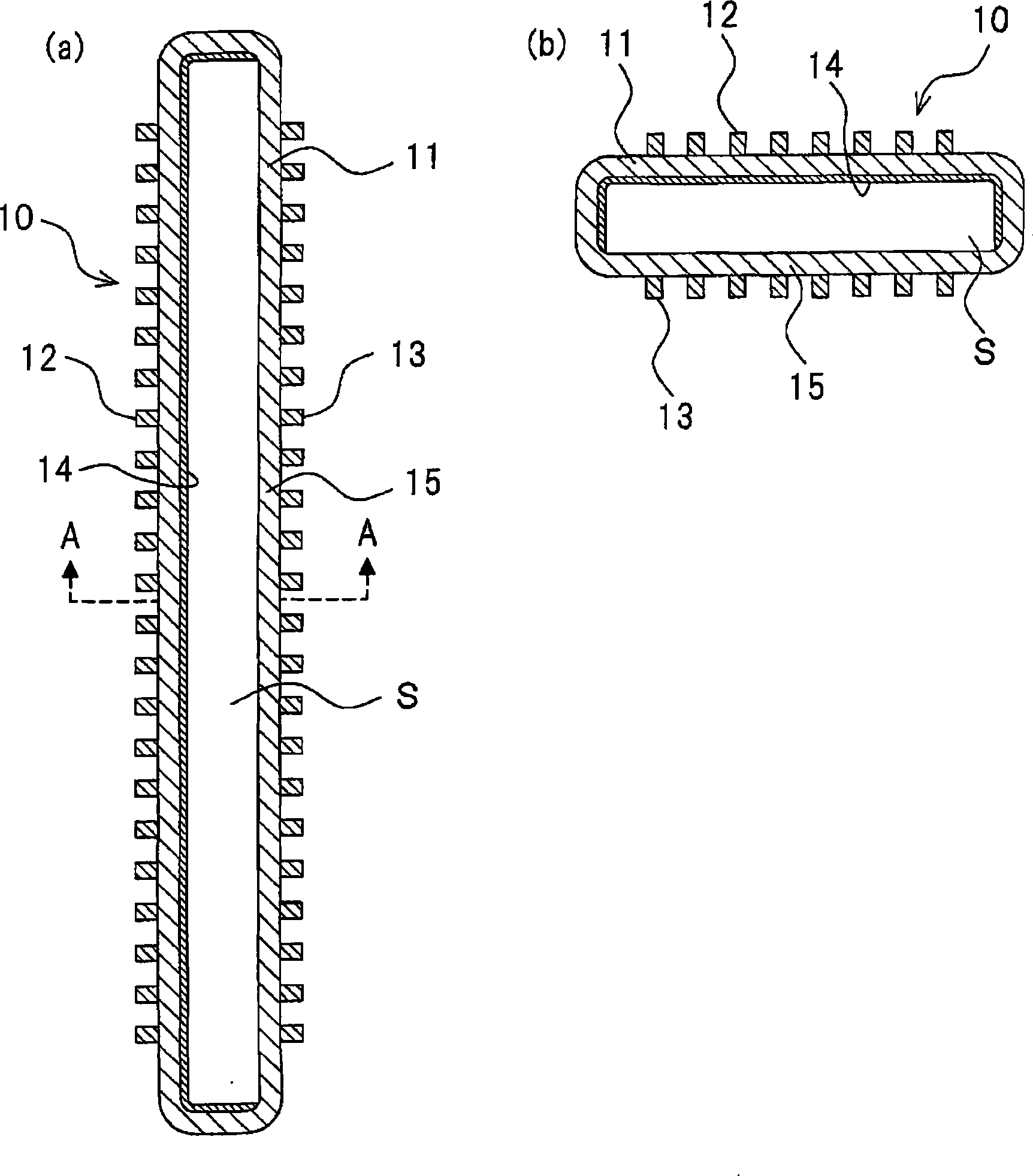

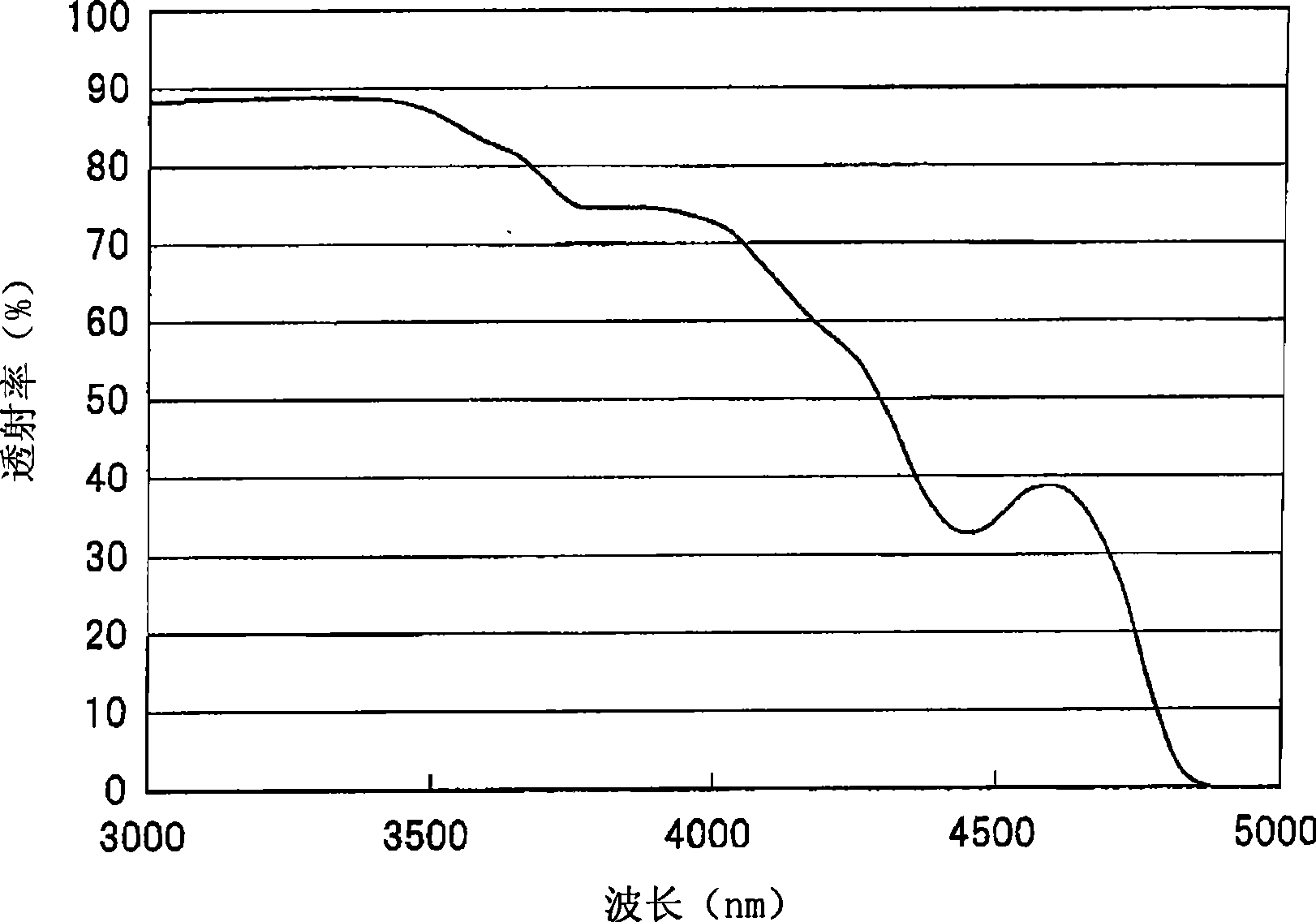

[0052] First, excimer lamps were fabricated with ultraviolet reflection films containing only silica particles as ultraviolet scattering particles, and ultraviolet reflection films with composition ratios of silica particles and alumina particles of 9:1 and 7:3, respectively. The central particle size of the silica particles and alumina particles constituting the ultraviolet reflective film, the transmittance of the ultraviolet reflective film, and the film thickness of the ultraviolet reflective film were measured, and then the excimer lamp was turned on to observe whether the ultraviolet reflective film peeled off.

[0053]The discharge vessel of the excimer lamp used in the experiment is made of synthetic quartz glass, with a size of 10×42×150mm and a thickness of 1.8mm. The enclosed gas is xenon gas, the gas pressure is 30kPa, and the size of the two electrodes is 30×100mm. In addition, the proportion of particles having a central particle diameter among the silica particle...

experiment example 2

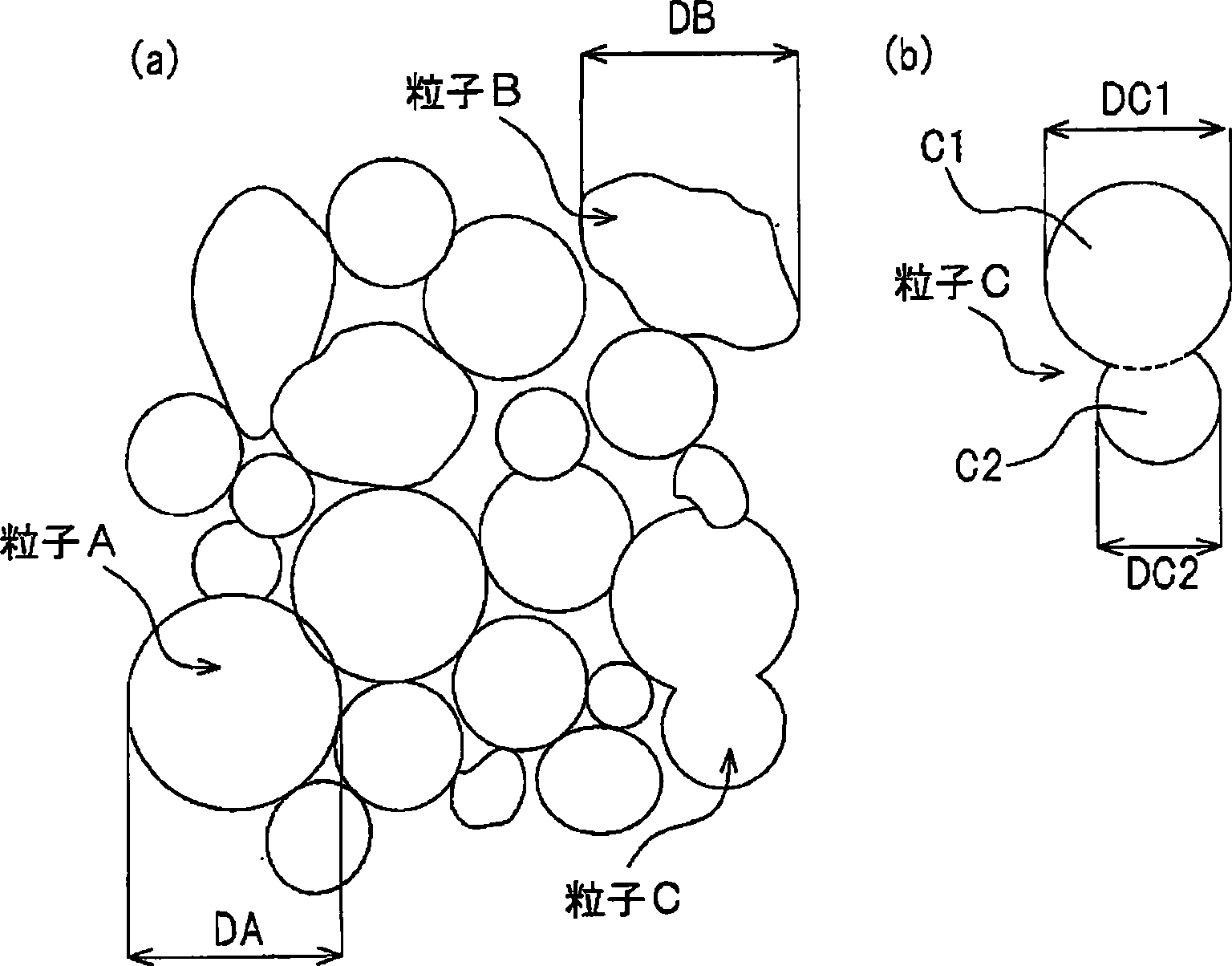

[0065] Figure 6 It is a table showing details of six types of excimer lamps 1 to 6 with different particle diameter ranges, central particle diameters, and composition ratios of silica particles and alumina particles of the discharge vessel used in the experiment.

[0066] Figure 7 is for Figure 6 The excimer lamps 1 to 6 shown are graphs of relative illuminance values when the illuminance of vacuum ultraviolet light in the wavelength region of 150 to 200 nm is measured, and the illuminance in the above wavelength region of the excimer lamp without the ultraviolet reflective film is 1.

[0067] The illuminance measurement was carried out as follows: an excimer lamp was fixed on a support table made of ceramics arranged inside an aluminum container, and an ultraviolet illuminometer was fixed at a position 1 mm away from the surface of the excimer lamp so as to face the excimer lamp. In the state where the internal atmosphere of the aluminum container is replaced with nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com