Antireflection film layer for photovoltaic glass, preparation method of antireflection film layer and solar cell module

A technology of anti-reflection film and photovoltaic glass, which is applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of penetration, difficulty in removal, easy entry of pollutants or water vapor, etc., and achieve excellent water resistance and moisture resistance. Effects of complexity and continuous stable power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

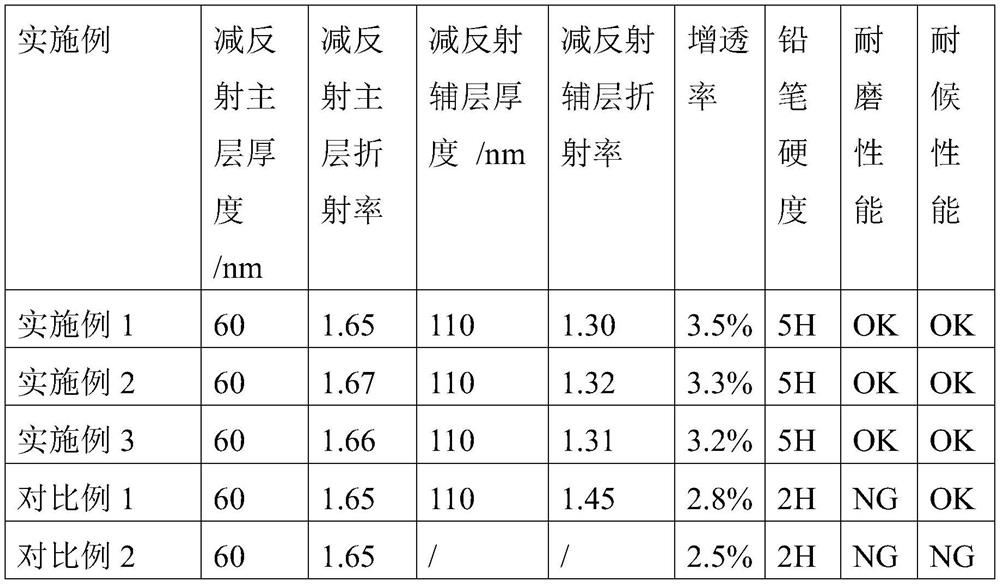

Examples

Embodiment 1

[0049] An antireflection film layer for photovoltaic glass, comprising a main antireflection layer arranged on a glass substrate, and an auxiliary antireflection layer arranged on the main antireflection layer;

[0050] Wherein, the anti-reflection main layer includes the following parts by weight as raw material components: 25 parts of nano-silica dispersion (average particle size is 10nm), hollow silica particles (purchased from Nikke Catalyst Chemical Co., Ltd. company, the average particle size is 50nm, and the mass fraction is 22 parts of methyl ethyl ketone silica sol) 22 parts, polymethyl methacrylate 1.5 parts, ethanol 90 parts.

[0051] The auxiliary anti-reflection layer includes the following parts by weight as raw material components: 30 parts of perfluorohexyl ethyl acrylate, 5 parts of isocyanate curing agent, 0.8 parts of nano-alumina (average particle size: 100 nm), acetic acid 40 parts of ethyl ester.

[0052] The preparation method of the above-mentioned ant...

Embodiment 2

[0056] An antireflection film layer for photovoltaic glass, comprising a main antireflection layer arranged on a glass substrate, and an auxiliary antireflection layer arranged on the main antireflection layer;

[0057] Wherein, the anti-reflection main layer includes the following parts by weight as raw material components: 30 parts of nano-silica dispersion (average particle size is 10nm), hollow silica particles (purchased from Nikke Catalyst Chemical Co., Ltd. company, the average particle size is 50nm, the mass fraction is 20% methyl ethyl ketone silica sol) 15 parts, polymethyl methacrylate 2.5 parts, ethanol 100 parts.

[0058] The auxiliary anti-reflection layer includes the following parts by weight as raw material components: 35 parts of perfluorohexyl ethyl acrylate, 6 parts of isocyanate curing agent, 0.7 parts of nano-alumina (average particle size: 100 nm), acetic acid 40 parts of ethyl ester.

[0059] The preparation method of the above-mentioned anti-reflectio...

Embodiment 3

[0063] An antireflection film layer for photovoltaic glass, comprising a main antireflection layer arranged on a glass substrate, and an auxiliary antireflection layer arranged on the main antireflection layer;

[0064] Wherein, the anti-reflection main layer includes the following parts by weight as raw material components: 15 parts of nano-silica dispersion (average particle size is 10nm), hollow silica particles (purchased from Nikke Catalyst Chemical Co., Ltd. company, the average particle size is 50nm, the mass fraction is 20% methyl ethyl ketone silica sol) 30 parts, polymethyl methacrylate 0.5 part, ethanol 85 parts.

[0065] The anti-reflection auxiliary layer comprises the following parts by weight as raw material components: 20 parts of perfluorohexyl ethyl acrylate, 3 parts of isocyanate curing agent, 1 part of nano-alumina (average particle size: 100 nm), acetic acid 50 parts of ethyl ester.

[0066] The preparation method of the above-mentioned anti-reflection fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com