Double-turntable type throwing pill strengthening cleaning machine

A cleaning machine, desktop technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of easy vibration and resonance, affecting the workshop environment, low machine efficiency, etc., to reduce vibration and resonance phenomenon, work The effect of less environmental pollution and convenient loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

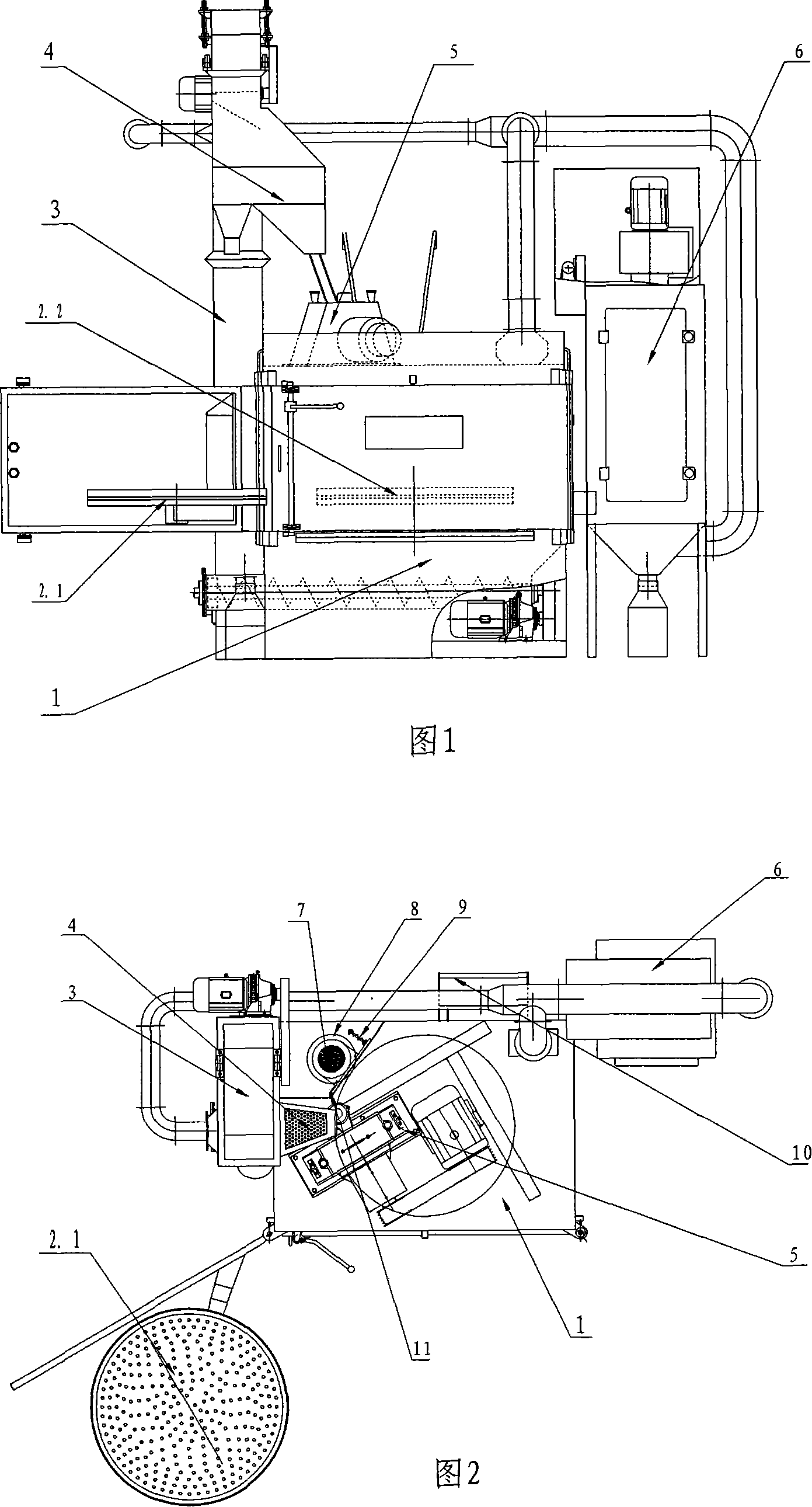

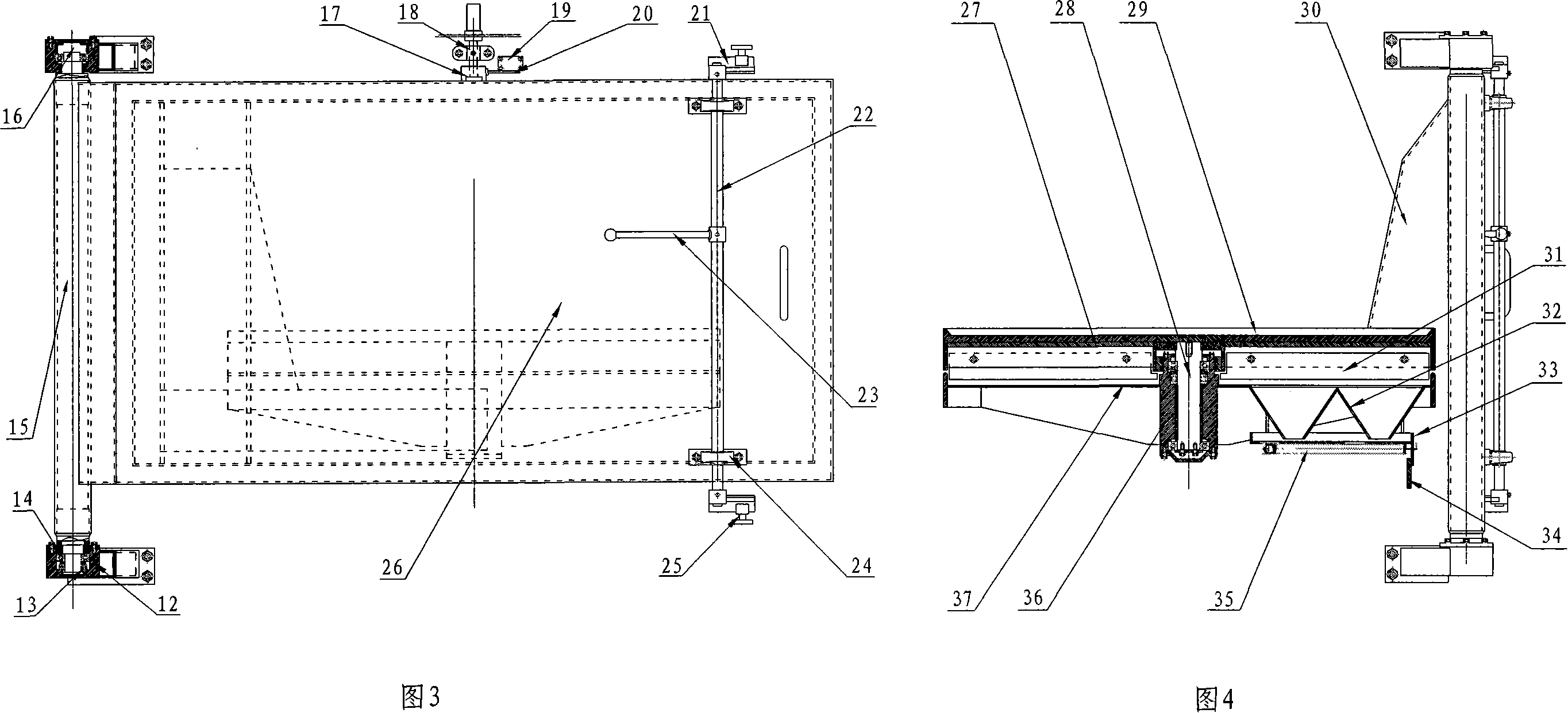

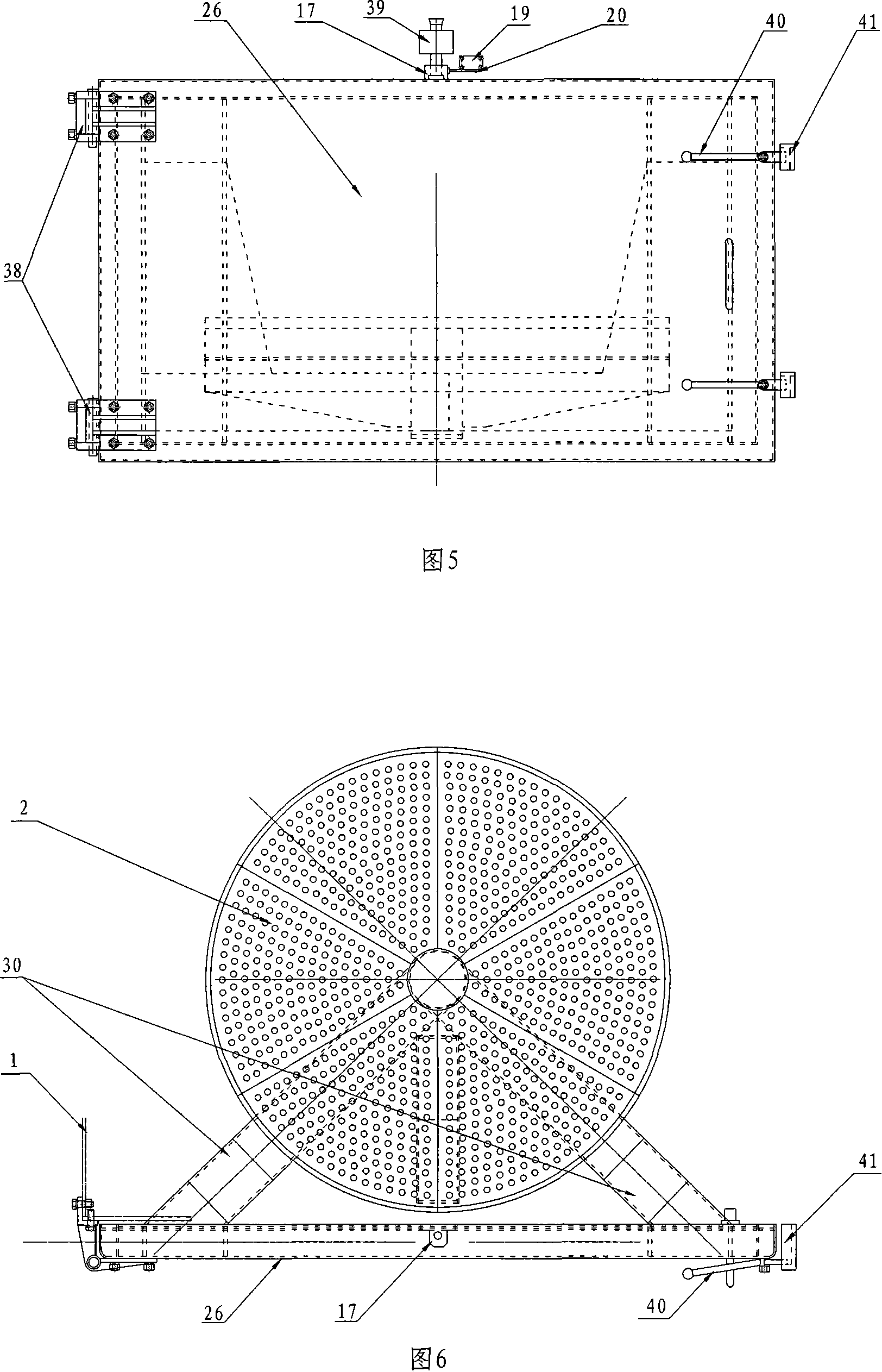

[0018] The double-turn table type shot blasting intensive cleaning machine is mainly composed of shot blasting chamber (1), shot blasting device (5), lifting mechanism (3), separator (4), rotary table (2), dust collecting mechanism (6) and The electric control system (10) is composed of the shot blasting device (5) arranged on the top of the shot blasting chamber (1), the lifting mechanism (3) is connected with the shot blasting chamber (1) as a whole, and is used to support the whole machine, and the separator ( 4) Connected between the lifting mechanism (3) and the shot blasting device (3), the dust collection mechanism (6) is respectively connected with the separator (4) and the shot blasting chamber (1) through the dust inlet pipe, and the electrical control system (10 ) main board is hooked outside the body, and is connected with each control part through the power line. The shot blasting chamber (1) has a door opening, two whole door doors (26), two whole door doors (26)...

Embodiment 2

[0020]The double-turn table type shot blasting intensive cleaning machine is mainly composed of shot blasting chamber (1), shot blasting device (5), lifting mechanism (3), separator (4), rotary table (2), dust collecting mechanism (6) and The electric control system (10) is composed of the shot blasting device (5) arranged on the top of the shot blasting chamber (1), the lifting mechanism (3) is connected with the shot blasting chamber (1) as a whole, and is used to support the whole machine, and the separator ( 4) Connected between the lifting mechanism (3) and the shot blasting device (5), the dust collecting mechanism (6) is respectively connected with the separator (4) and the shot blasting chamber (1) through the dust inlet pipe, and the electrical control system (10 ) main board is hooked outside the body, and is connected with each control part through the power line. The shot blasting chamber (1) has a door opening, two full-fan chamber body gates (26), and two full-fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com