Method for purifying forsythiaside A from forsythia extractive

A technology of forsythia extract and forsythiaside, which is applied in the field of medicine, can solve the problems of limiting the extraction process of forsythiaside A and reducing extraction efficiency, and achieve the effect of saving raw materials and improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

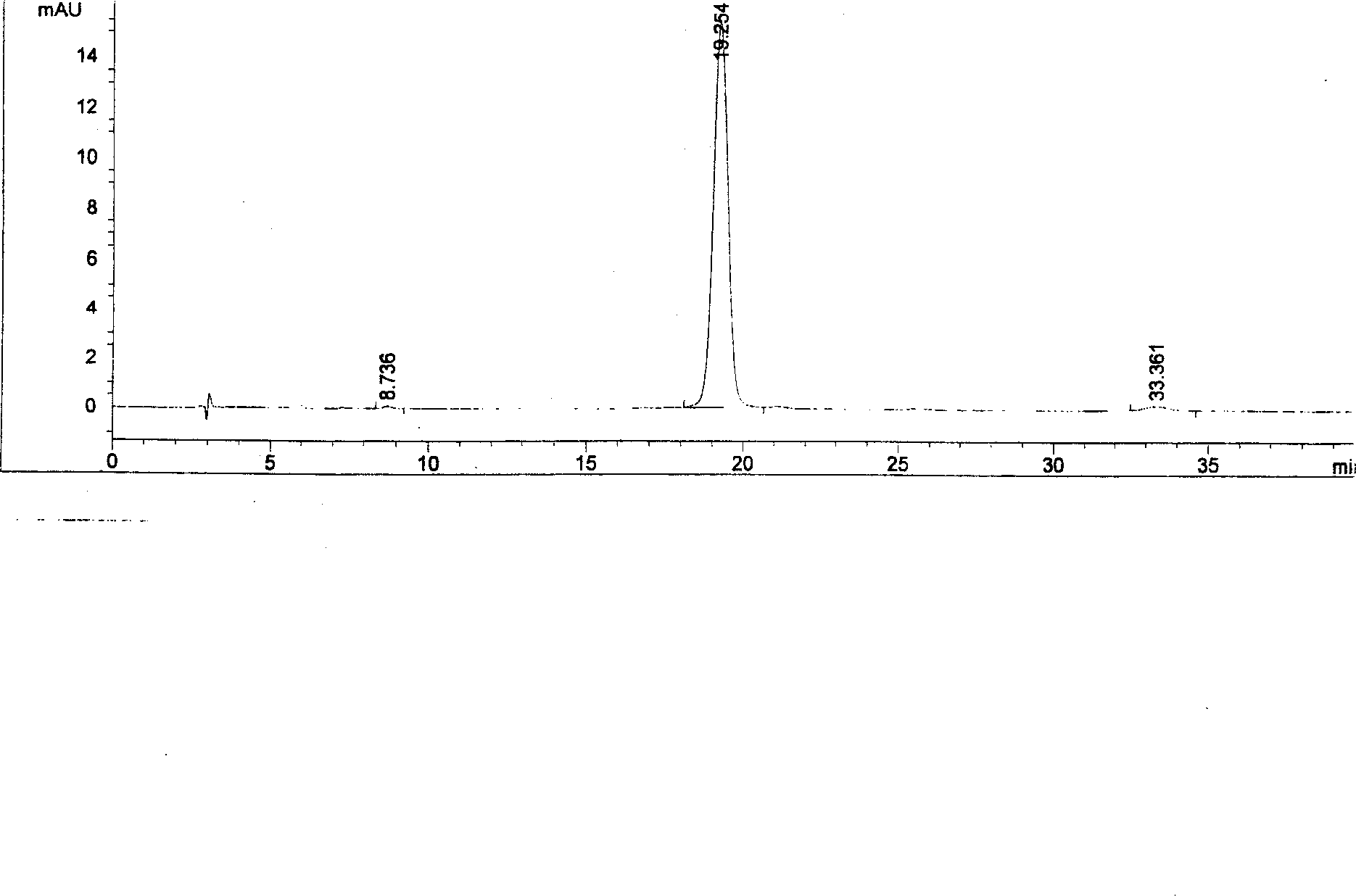

[0016] The crude silica gel was dry-packed into a glass column (aspect ratio of 1:15), and connected to a UV chromatograph. Forsythia extract dry powder 10 grams, mixed with 20 grams of 100 mesh coarse silica gel in a mortar, solid loading, sample volume 1:30, with ethyl acetate-acetone-water (8:2:0.5) as the flow Phase elution, control flow rate 10ml / min, collect forsythiaside A peak, combine, concentrate under reduced pressure, vacuum dry; then apply RP-18 silica gel column (diameter-height ratio 1:12, loading amount 1:50) for purification , eluted with methanol-water (3:7), collected the peaks of forsythiaside A, combined, concentrated under reduced pressure, and dried in vacuum to obtain forsythiaside A product.

Embodiment 2

[0018] The crude silica gel was dry-packed into a glass column (aspect ratio of 1:15), and connected to a UV chromatograph. Forsythia extract dry powder 10 grams, mixed with 20 grams of 100 mesh coarse silica gel in a mortar, solid loading, sample volume 1:30, with ethyl acetate-acetone-water (9:0.5:0.5) as the flow Phase elution, control flow rate 8ml / min, collect forsythiaside A peak, combine, concentrate under reduced pressure, vacuum dry; Then apply RP-18 silica gel column (diameter-to-height ratio 1: 12, loading amount is 500 grams) to purify , eluted with methanol-water, the ratio is 4:6, the peaks of forsythiaside A are collected, combined, concentrated under reduced pressure, and dried in vacuum to obtain forsythiaside A.

Embodiment 3

[0020] The crude silica gel was dry-packed into a glass column (aspect ratio of 1:15), and connected to a UV chromatograph. Forsythia extract dry powder 10 grams, mixed with 200 mesh coarse silica gel 50 grams in a mortar, solid loading, sample volume 1:60, with ethyl acetate-methanol-water (1:4.5:4.5) as the flow Phase elution, control flow rate 12ml / min, collect forsythiaside A peak, combine, concentrate under reduced pressure, vacuum dry; then put on RP-18 silica gel column (diameter-to-height ratio 1:12, loading volume: 1:100) Purify, elute with methanol-water, the ratio is 1:9, collect the peaks of forsythiaside A, combine them, concentrate under reduced pressure, and dry in vacuum to obtain forsythiaside A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com