Liquid treatment device and method

A liquid, distillation device technology, applied in chemical instruments and methods, energy waste water treatment, water/sewage treatment, etc., can solve problems such as expensive, time-consuming operation, and production shutdown

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

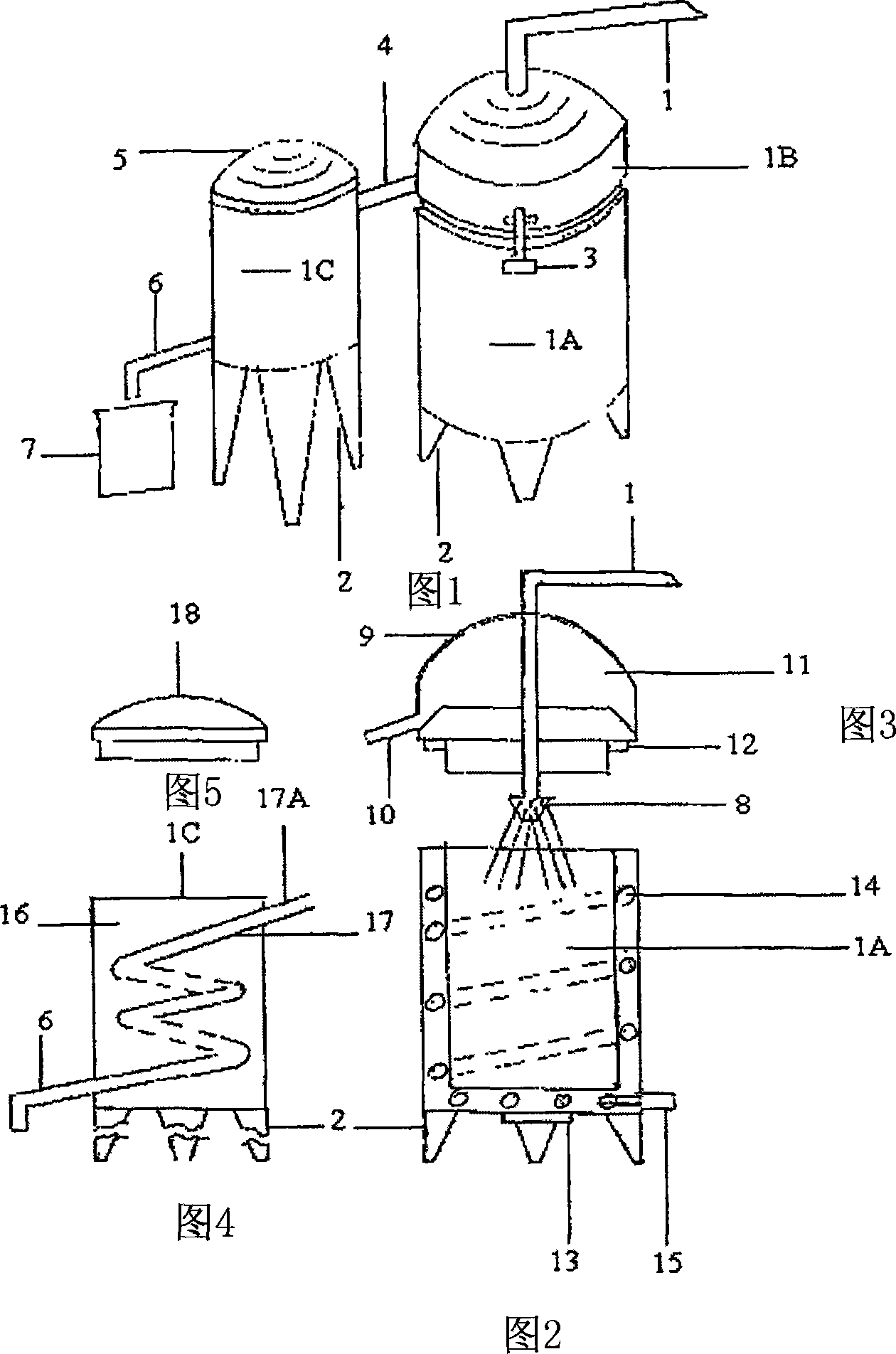

[0136] According to Fig. 1, this distillation device is made up of these two big components of a boiling cylinder 1A with a top cover 1B and a condenser 1C. The pressure water inlet pipe 1 is fixed on the top cover 1B and is used for providing the liquid that needs to be distilled. The second pipe 4 is responsible for conveying the condensed steam flowing out of the top part 1B to the condenser 1C. A pair of clamps 3 are respectively installed on the top cover 1B and the boiling cylinder 1A to fasten these two parts.

[0137] According to further illustrations in FIGS. 2 and 3 , the pipe 1 extends downward into the top cover 1B and passes through the top cover 1B to the boiling cylinder 1A. Although Fig. 2 and Fig. 3 show that the terminal of the pipeline 1 is relatively above the boiling cylinder 1A; but when the top cover 1B is placed on the boiling cylinder 1A, the terminal of the pipeline 1 will be near the center of the top of the boiling cylinder 1A. The design that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com