Composite material of Nano grains of silver and carriers of polymer microballons, and preparation method

A technology of silver nanoparticles and composite materials, applied in the field of nanomaterials and composite materials, can solve problems such as reducing the application range of materials, and achieve the effects of deodorizing part of ultraviolet rays, mild reaction, and improving load rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Step 1: Add 0.039 mmol (162 mg) of styrene-terminated poly-N-isopropylacrylamide, 0.9 mmol (96 mg) of styrene, 3 mmol (159 mg) of acrylonitrile, and azobis Isobutyronitrile 0.039mmol (7mg), ethanol / water (volume ratio 7 / 3) mixed medium 5ml, ultrasonic vibration to make it fully dissolved, the mixed solution was refrigerated vacuum, thawing repeated three times or continue to pass high-purity nitrogen for 30min , and then seal the stoppered test tube, place it in a constant temperature shaking water bath at 60° C. with a vibration frequency of 160 r / min, and react for a predetermined time (20 hours). Take out the stoppered test tube, first centrifuge the reaction solution, redisperse it in the water medium, and further dialysis and purify it in the cellulose dialysis membrane for 5 days to remove impurities such as unreacted monomers, freeze-dry to obtain a polymer with a special shape on the surface Microspheres.

[0016] Second step: take by weighing the special form ...

Embodiment 2

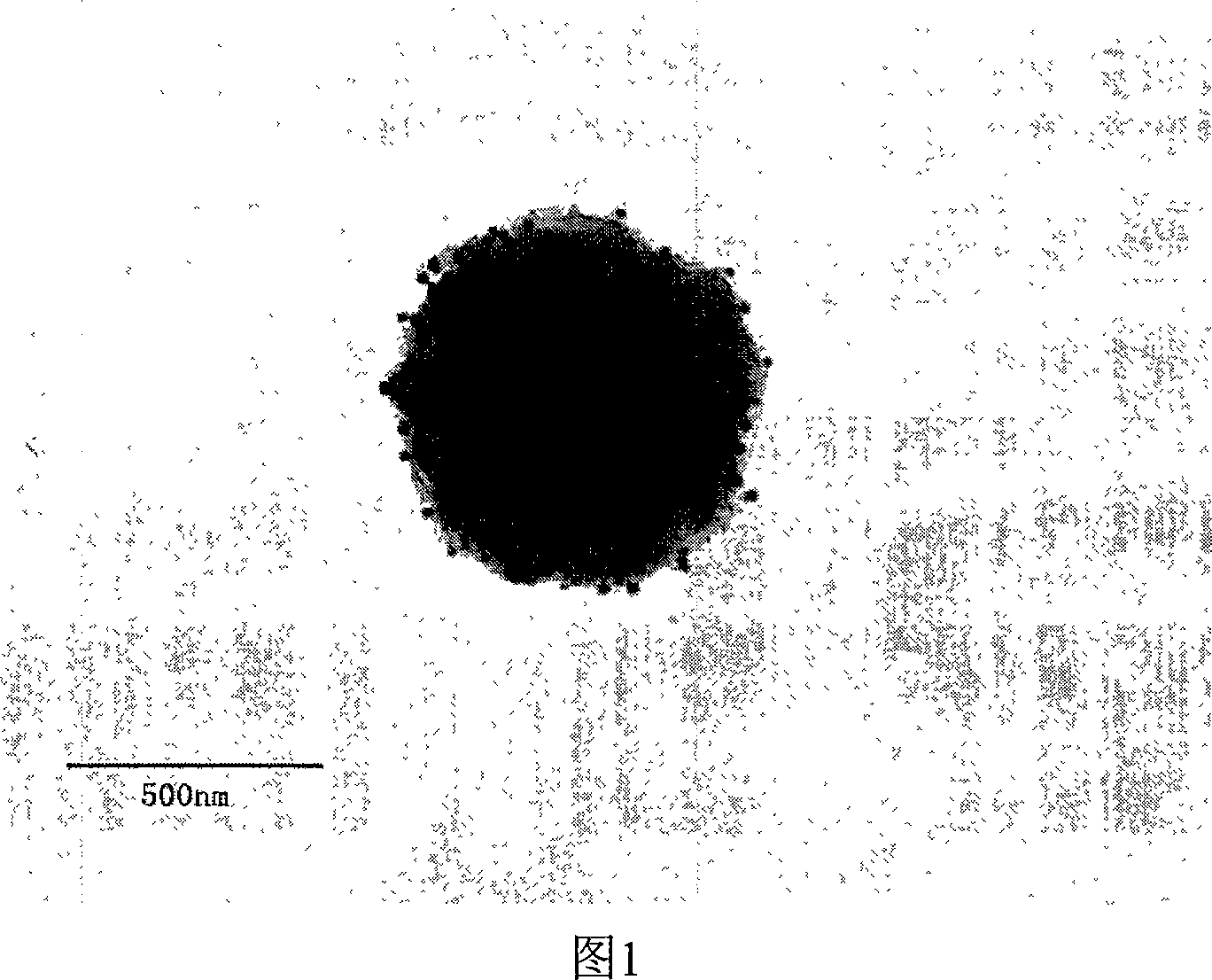

[0018] Take by weighing 0.025mmol (460mg) of special form polymer microspheres obtained in the first step in Example 1, measure ethanol 28ml, water 12ml, add in a 100ml three-necked flask, stir and mix evenly, weigh silver nitrate 0.03~0.4mmol ( 5.1 ~ 68 mg), into the three-necked flask, after fully stirring for 2 hours, put the three-necked flask in a 65°C oil bath, react until the predetermined time (8 ~ 10 hours), take out the three-necked flask, cool naturally, take out the product after 7000r Centrifuge at 1 / min to remove the upper liquid, dissolve it in water, and centrifuge three times to obtain a stable dispersed silver nanoparticle / polymer microsphere composite material with a special shape. The particle size of the silver nanoparticle is about 10-50nm.

Embodiment 3

[0020] Step 1: Add 0.0234 mmol (196 mg) of styrene-terminated poly-N-vinylacetamide, 0.6 mmol (64 mg) of styrene, 3.3 mmol (175 mg) of acrylonitrile, and azobis Isobutyronitrile 0.039mmol (7mg), ethanol as the reaction medium 5ml, ultrasonic vibration to make it fully dissolved, the mixed solution was subjected to freezing vacuum, thawing and repeating three cycles or continuous high-purity nitrogen gas for 30min, and then sealed the stoppered test tube. Place the stoppered test tube in a constant temperature shaking water bath at 70°C with a vibration frequency of 120r / min, and react for a predetermined time (8 hours). Take out the stoppered test tube, first centrifuge the reaction solution, redisperse it in the water medium, and further dialysis and purify it in the cellulose dialysis membrane for 5 days to remove impurities such as unreacted monomers, freeze-dry to obtain a polymer with a special shape on the surface Microspheres.

[0021] The second step: Weigh 0.025mmol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap