Method for processing organic wastewater

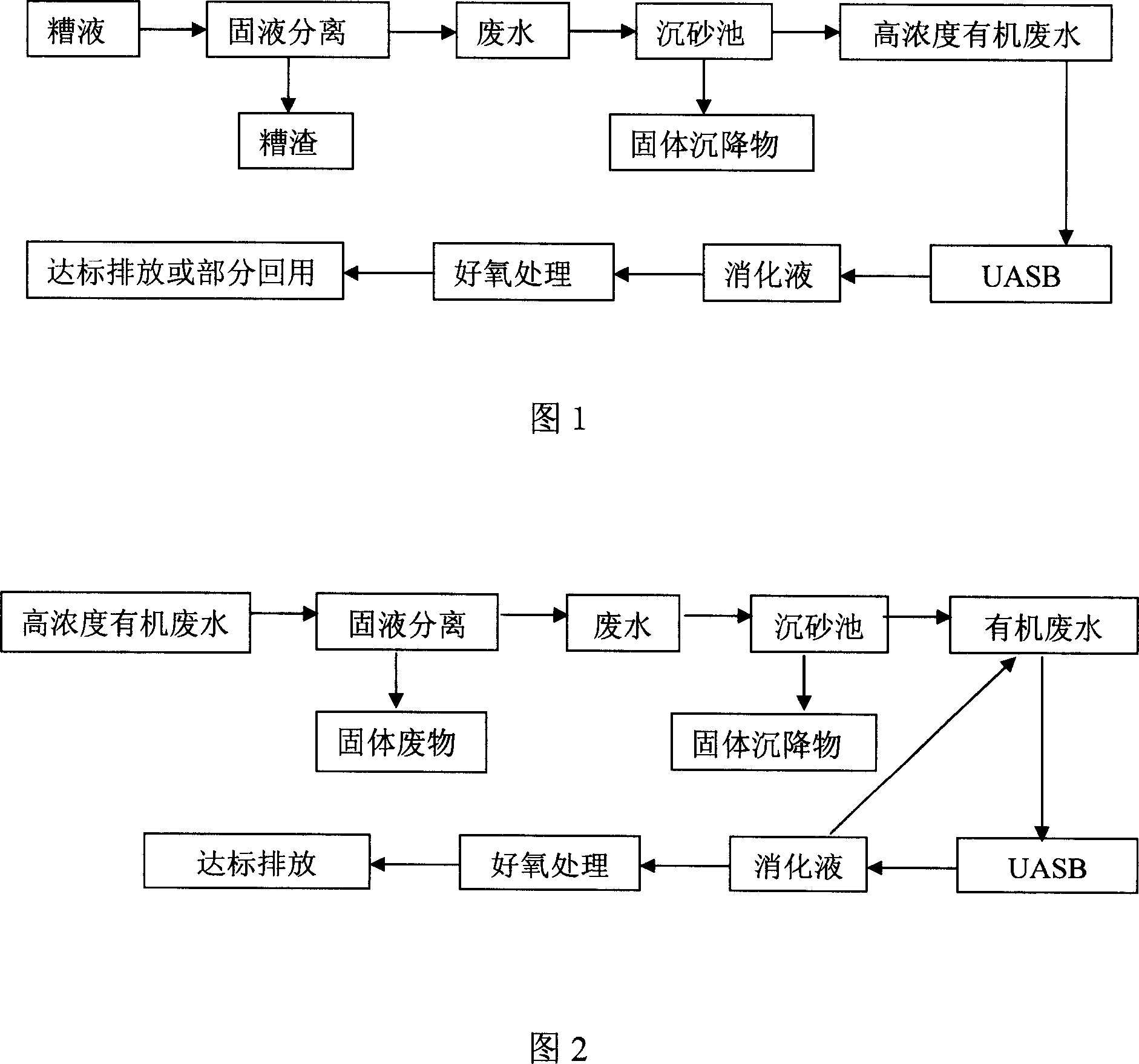

A technology for organic waste water treatment and waste water, applied in the direction of anaerobic digestion treatment, etc., can solve the problems of reducing the effective volume of the reactor, increasing the pH value of the waste water, and stopping the reactor, so as to improve the capacity of treating waste water, ensure stable operation, and ensure normal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, the UASB reactor step of wheat alcohol waste water treatment equipment set up adjustment pool, high-concentration alcohol waste water first passes through solid-liquid preliminary separation, puts into waste water pool after the grit chamber settles, and the pH value of the alcohol waste water to be treated is 4.0, will The treated digestive juice is partially refluxed from the upper outlet of the UASB reactor to the regulating tank with a reflux ratio of 1.5. The untreated waste water is mixed in the regulating tank. The pH value of the mixed solution is measured to be 6.5. The speed is controlled at 1.0m / h, and the reactor is running. Use a precision pH meter and a COD quick tester to test the wastewater and digestive fluid, and the results are as follows:

[0015] Test data before and after reflow

[0016] alcohol wastewater

Embodiment 2

[0017] Embodiment 2, the UASB reactor step of dried potato alcohol wastewater treatment equipment set up a regulating tank, the high-concentration alcohol wastewater is put into the wastewater tank after the preliminary solid-liquid separation, and the grit chamber settles, and the pH value of the alcohol wastewater to be treated is measured as 5.5. Return the treated digestive liquid from the upper outlet of the UASB reactor to the regulating tank, and mix it with untreated wastewater. The reflux ratio is 1, and the pH value of the mixed liquid is 6.2. Pump the mixed liquid into the reactor , the upflow velocity is controlled at 1.0m / h, and the reactor is running. Use a precision pH meter and a COD quick tester to test the wastewater and digestive fluid, and the results are as follows:

[0018] Test data before and after reflow

[0019] alcohol wastewater

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com