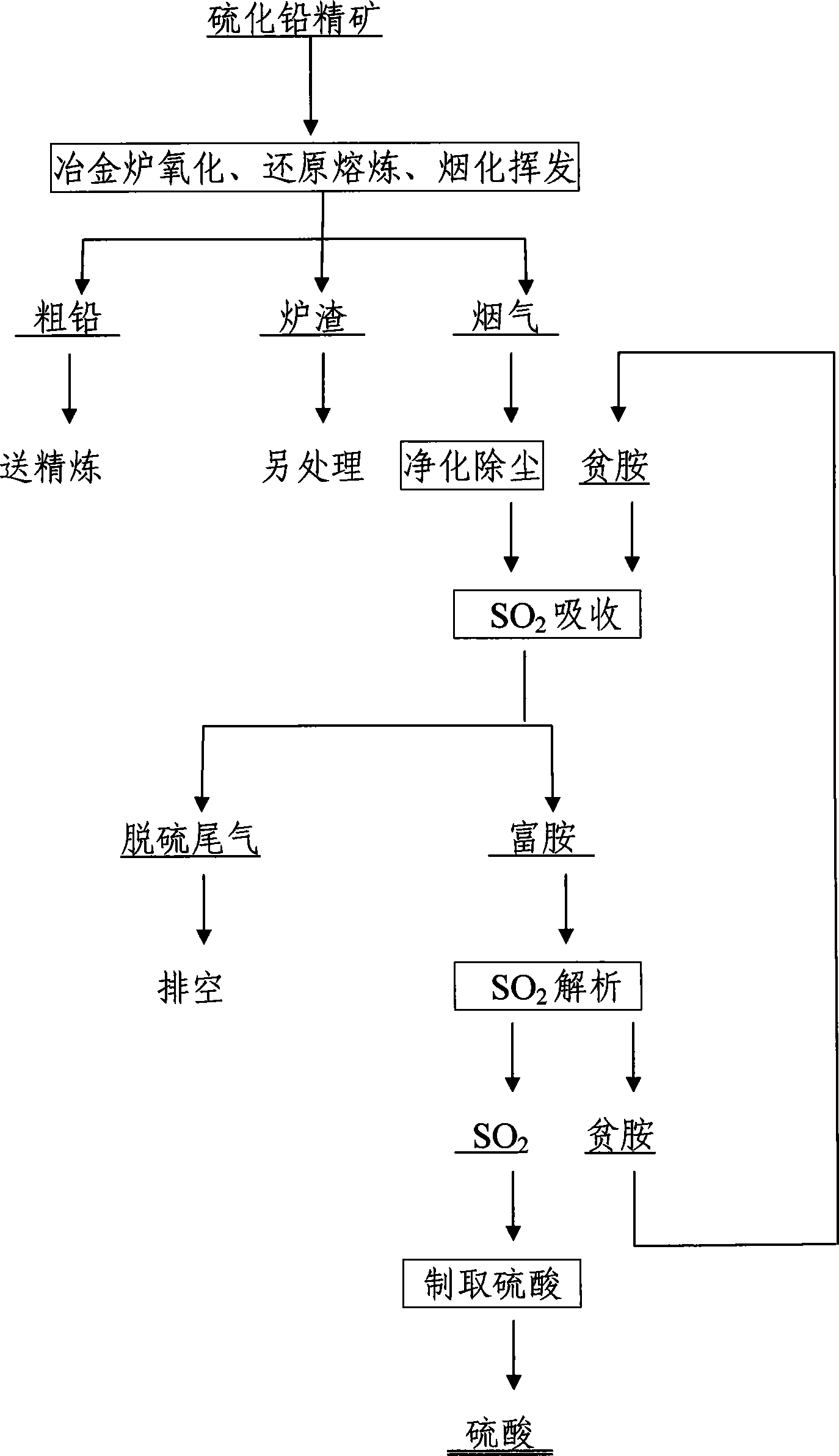

Sulfide plumbum concentrate continuous oxidation-reduction smelting and slag fuming exhaust amine absorbing acid-production technique

A technology of lead sulfide and tail gas amine, which is applied in the direction of sulfur trioxide/sulfuric acid, chemical instruments and methods, and separation of dispersed particles. It can solve problems such as waste of resources, health hazards of employees, and high turnover of materials, and reduce operating costs. Effect of improving environmental protection conditions and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The lead sulfide concentrate is added to an Ausmelt furnace for top-blowing and sinking smelting with a spray gun for smelting, and oxidation smelting-reduction smelting-fume volatilization is carried out continuously in the same Ausmelt furnace, and finally the discardable The slag is discharged out of the melting furnace. Flue gas volume and flue gas SO produced by the three smelting processes 2 The concentration fluctuates greatly, and there are 4 hours of flue gas SO in every 8 hours in the oxidation smelting stage 2 The concentration is 12%, there is 1.5 hours of flue gas SO in every 8 hours in the reduction smelting stage 2 The concentration is 4%, and there are 2 hours of flue gas SO in every 8 hours in the slag fuming and volatilization stage 2 The concentration is 0.02%, and there is 0.5 hours of flue gas SO in every 8 hours during the slag release stage 2 The concentration is 0.02%. Such flue gas SO 2 The concentration fluctuates too much, and it is disch...

Embodiment 2

[0015] The lead sulfide concentrate is added to an Ausmelt furnace for top-blowing and sinking smelting with a spray gun for smelting, and oxidation smelting-reduction smelting-fume volatilization is carried out continuously in the same Ausmelt furnace, and finally the discardable The slag is discharged out of the melting furnace. Flue gas volume and flue gas SO produced by the three smelting processes 2 The concentration fluctuates greatly, and there are 4 hours of flue gas SO in every 8 hours in the oxidation smelting stage 2 The concentration is 15%, and there is 1.5 hours of flue gas SO in every 8 hours in the reduction smelting stage 2 The concentration is 1%, and there are 2 hours of flue gas SO in every 8 hours in the slag fuming and volatilization stage 2 The concentration is 0.5%, and there is 0.5 hours of flue gas SO in every 8 hours during the slag release stage 2 The concentration is 0.008%. Such flue gas SO 2 The concentration fluctuates too much, and it is d...

Embodiment 3

[0017] The lead sulfide concentrate is added to an Ausmelt furnace for top-blowing and sinking smelting with a spray gun for smelting, and oxidation smelting-reduction smelting-fume volatilization is carried out continuously in the same Ausmelt furnace, and finally the discardable The slag is discharged out of the melting furnace. Flue gas volume and flue gas SO produced by the three smelting processes 2 The concentration fluctuates greatly, and there are 3.5 hours of flue gas SO in every 8 hours in the oxidation smelting stage 2 The concentration is 14%, and there are 2.5 hours of flue gas SO in every 8 hours in the reduction smelting stage 2 The concentration is 3%, and there is 1.5 hours of flue gas SO in every 8 hours in the slag fuming and volatilization stage 2 The concentration is 0.35%, and there is 0.5 hours of flue gas SO in every 8 hours during the slag release stage 2 The concentration is 0.01%. Such flue gas SO 2 The concentration fluctuates too much, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com