Process for using DC water source cold-heat power supply

A technology of cold and heat source and water source, which is applied in the field of efficient utilization of direct-flow water source cold and heat source, can solve the problems of low heat exchange performance, large heat exchange equipment, blockage of heat exchange equipment, etc., and achieves obvious environmental protection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

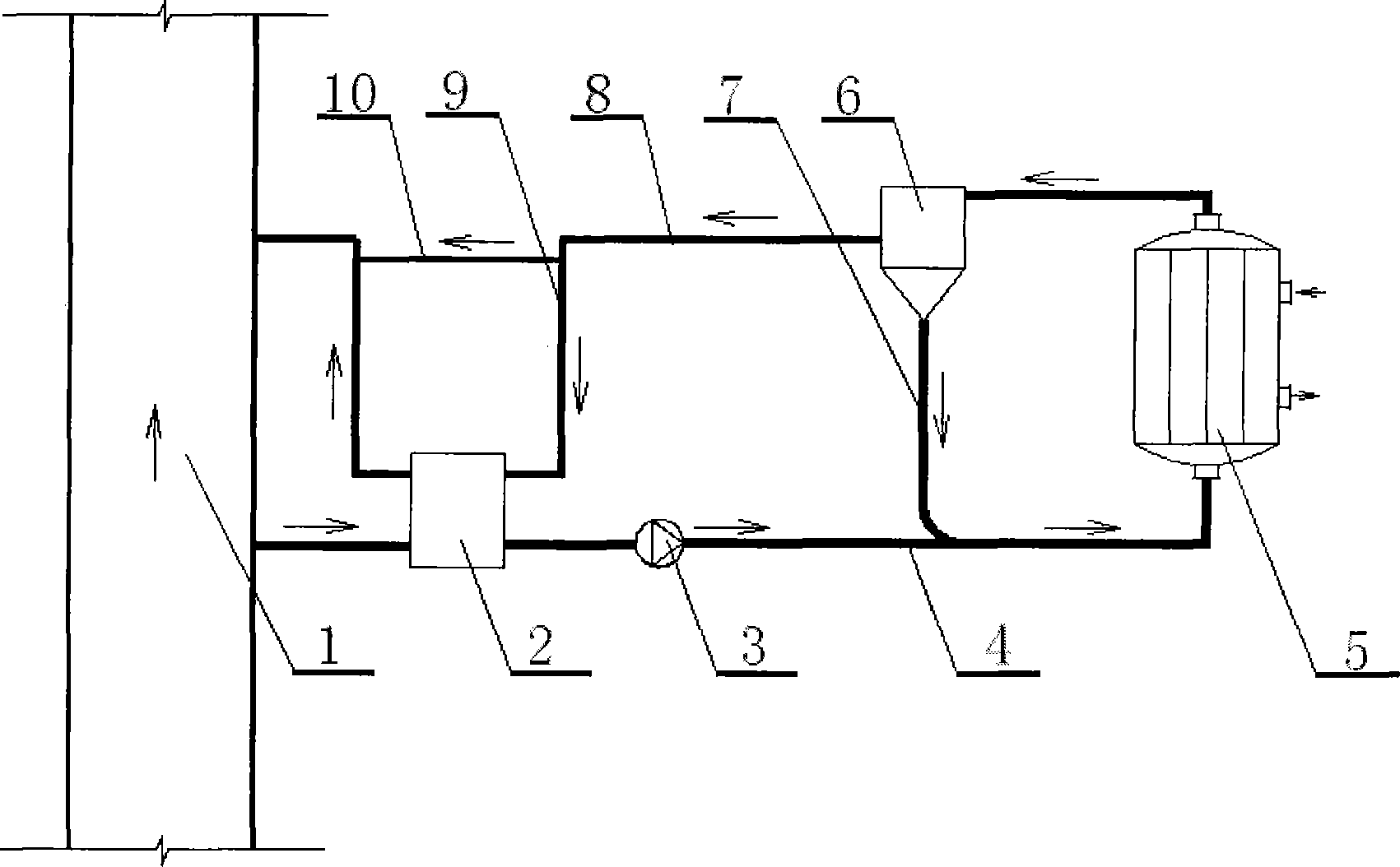

[0012] As shown in the attached figure, firstly start the water pump 3 to draw the direct-flow water source from the direct-flow water source pipe network 1 through the direct-flow water source inlet pipe 4 into the automatic water intake and decontamination device 2, large-scale dirt is removed, and then passes through the direct-flow water source inlet pipe 4 Entering the vertical fluidized bed heat exchange equipment 5, the once-through water source adds solid particles before entering the heat exchange equipment, and the solid particles continuously pass through the flow boundary layer in the movement with the fluid to achieve the function of strengthening heat exchange; while relying on solid The continuous contact between the particles and the heat exchange wall surface and the scouring of the particles on the wall surface can effectively remove the dirt deposited on the heat exchange wall surface. A solid-liquid separator 6 is installed on the straight-through water sour...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com