High voltage ignition wire and method of manufacture

A high-voltage ignition wire and mixture technology, which is applied in the directions of combustion ignition, combustion method, and ignition using electric sparks, can solve the problems of high temperature resistance, easy aging, and short service life of the ignition wire, and achieve advanced and simple technology. Service life, reasonable structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

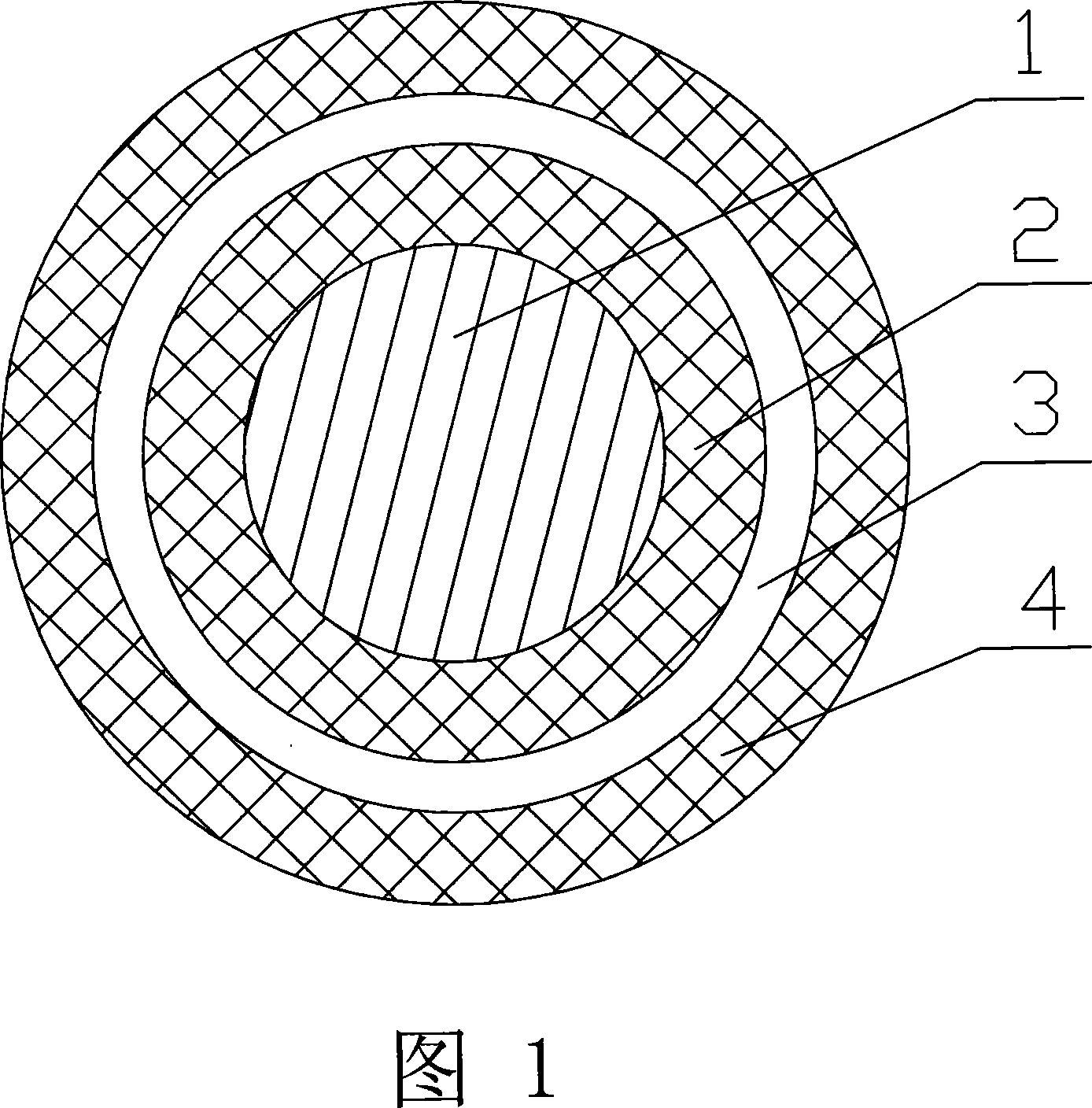

[0019] On the conductor 1, the inner insulation layer 2 of the mixture is first extruded, the braided layer 3 of alkali-free glass fiber yarn is woven on the inner insulation layer 2 of the mixture, and the outer insulation layer 4 of the mixture is extruded on the braided layer 3 . The mixture of the insulating layer contains the following percentages by weight: vulcanizing agent BPO 1.5-2%, titanium dioxide rutile 2R-9401-1.5%, PBN (phenylenediamine) antioxidant 2-3%, formazan Base vinyl silicone rubber compound 94-95%.

Embodiment 2

[0021] (1) The weight percentage is: vulcanizing agent BPO 1.5-2%, titanium dioxide rutile 2R-9401-1.5%, PBN anti-aging agent (phenylenediamine) 2-3%, methyl vinyl silicone rubber 94-95% of the rubber compound is mixed in an open mill to form a uniform mixture;

[0022] (2) Extrude the mixture with a rubber extruder, evenly wrap it on the conductor, and heat and vulcanize it in an oven to form the inner insulating layer 2. The temperature of the oven is 180-200° C., and the vulcanization and setting time is 2-3 minutes;

[0023] (3) After braiding the alkali-free glass fiber yarn weaving layer 3 with a braiding machine on the inner insulating layer 2, heat and dry, the temperature of the heat and dry is 120-150 ° C, and the time is 1-2 minutes;

[0024] (4) Extrude the mixture on the alkali-free glass fiber yarn braided layer 3 that is heated and dried, and heat and vulcanize in an oven to form an outer insulating layer 4. The vulcanization temperature is 180-200° C., and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com