Adjustable fiber filter

A fiber filter, adjustable technology, applied in the direction of gravity filter, filtration separation, loose filter material filter, etc., can solve the problem of high filtration resistance, high-precision water quality that cannot adjust fiber porosity, and fiber bundle filtration Material compaction and other problems, to achieve the effect of high filtration precision, long filtration cycle and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

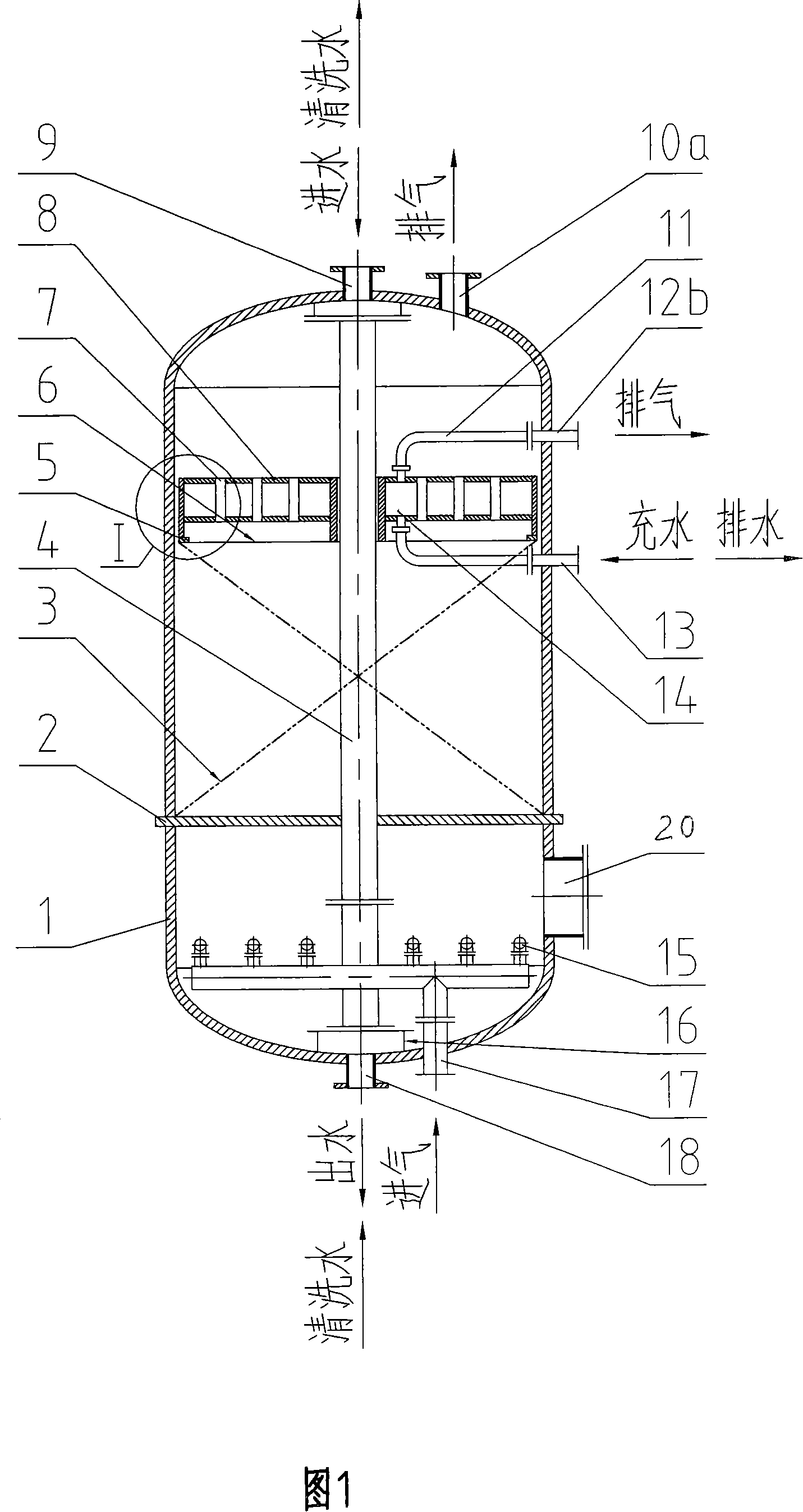

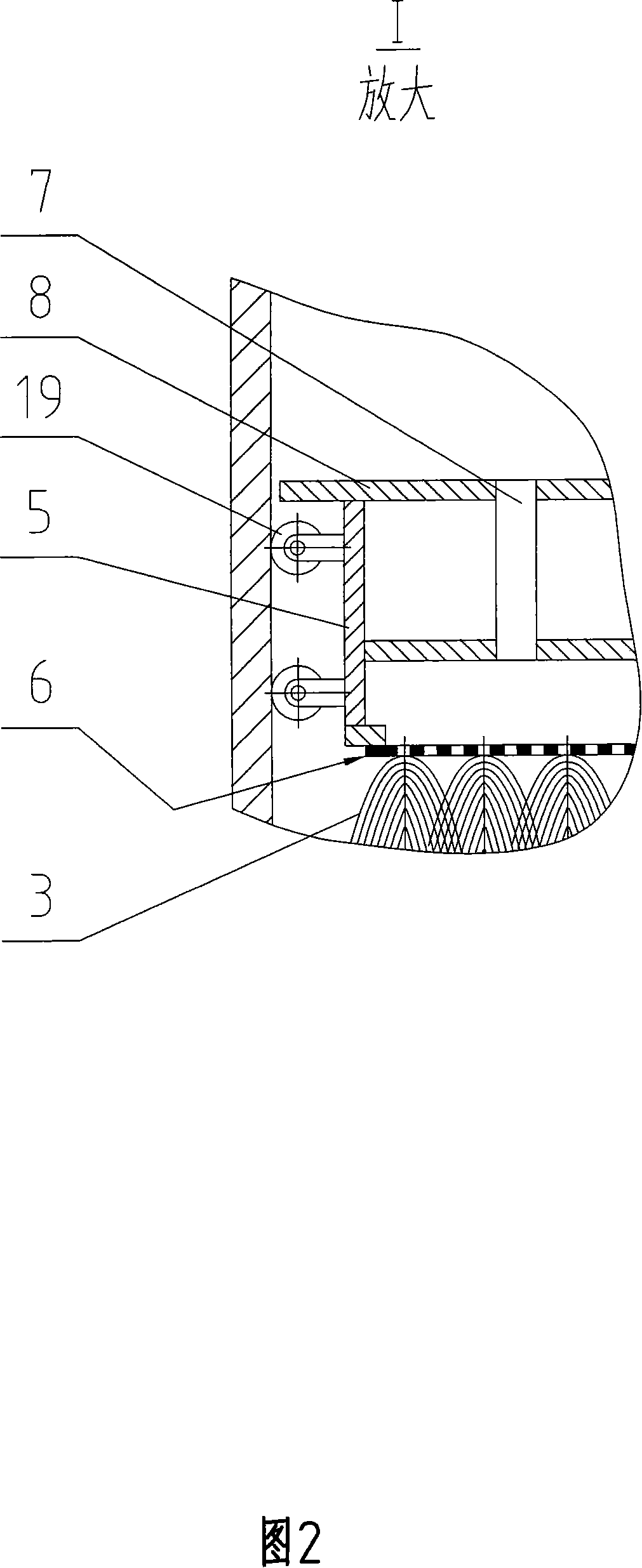

[0012] Embodiment 1: Referring to Figures 1 and 2, the adjustable fiber filter of this embodiment is a forward filter structure, which has a shell 1, and the shell 1 is composed of upper and lower heads and a middle cylinder through welding. A water inlet 9 and an exhaust port 10a are provided on the upper head of the housing 1, and a water outlet 18 and an air inlet 17 of the gas distribution device 15 are provided on the lower head of the housing 1. In the housing 1 The lower end is provided with a fixed orifice plate 2, and the upper end of the housing 1 is provided with a floating orifice plate 6. The fiber bundle filter material 3 is placed between the fixed orifice plate 2 and the floating orifice plate 6, and the two ends of the fiber bundle filter material 3 are respectively connected to the The fixed orifice plate 2 and the floating orifice plate 6 are fixedly connected. A manhole 20 is provided on the housing 1 . A filter material density adjusting device 8 is arran...

Embodiment 2

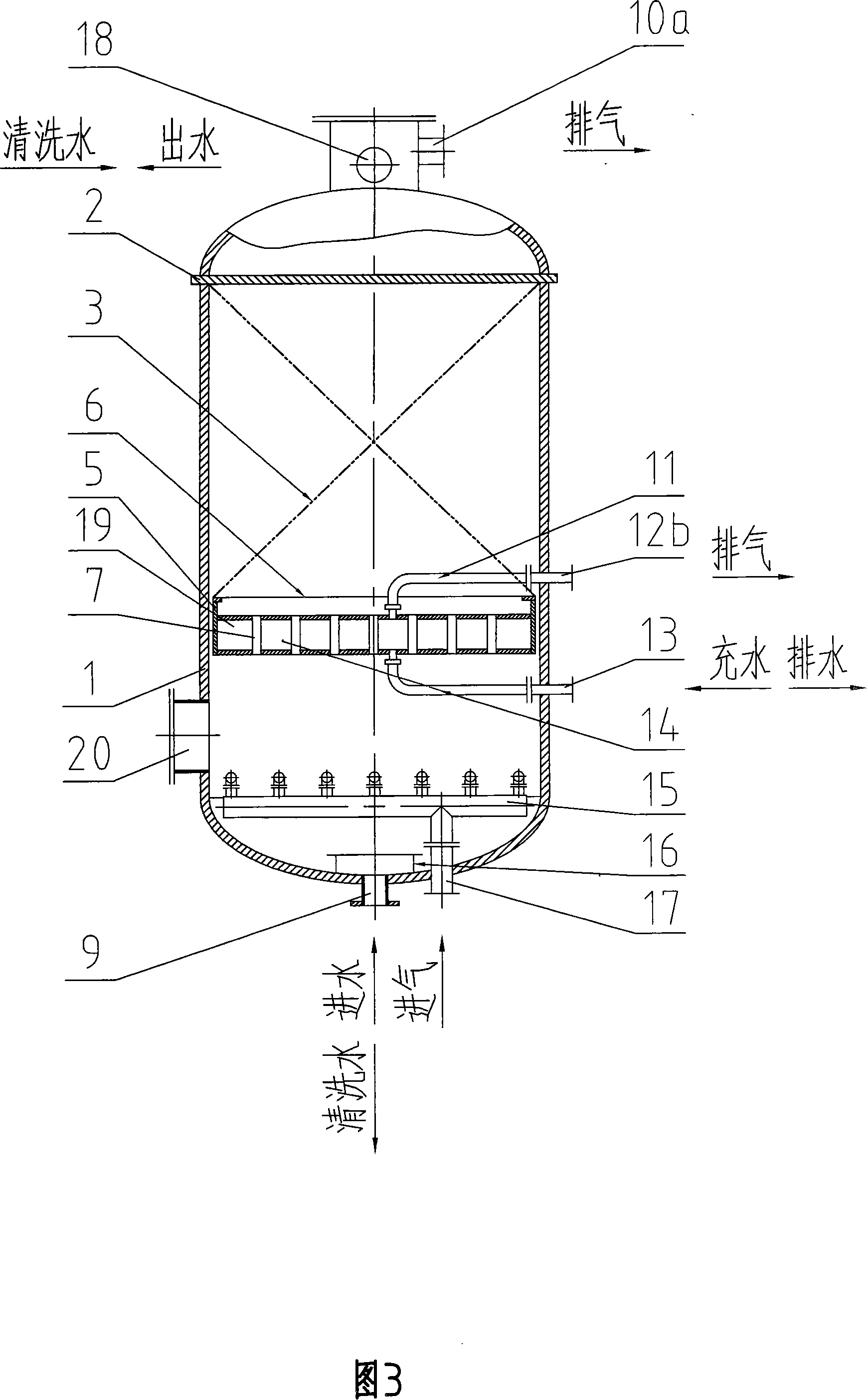

[0014] Embodiment 2: With reference to Fig. 3, the adjustable fiber filter of the present embodiment is a reverse filter structure, and its basic structure is the same as that of Embodiment 1, the only difference is that the water outlet 18 (i.e. the cleaning water inlet) is located in the shell On the upper head of the body 1, the water inlet 9 (that is, the cleaning water outlet) is set on the lower head of the shell 1, the fixed orifice 2 is set on the upper end of the shell 1, and the floating orifice 6 is set in the shell 1 At the lower end, the filter material density adjustment device 8 is arranged in the housing 1 and located below the fiber bundle filter material 3 . In the center of the housing 1 there is no guide support pipe 4 for the filter material density adjustment device 8 .

[0015] Working principle: when filtering, open the water inlet 9, the filter material density adjustment device 8 becomes an empty tank (not filled with water) and becomes a floating tan...

Embodiment 3

[0016] Embodiment 3: Referring to Figure 4, this adjustable fiber filter is suitable for application in a filter pool. Its structure is basically the same as that of Embodiment 1, the only difference is that the shell 1 is a pool-shaped structure made of steel and concrete. In the center of the housing 1 there is no guide support pipe 4 for the filter material density adjustment device 8 . There is no guide wheel 19 in contact with the housing 1 on the side wall of the frame 5 of the filter material density adjusting device 8 . Its working principle is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com