Double main bear multiple hanging point crane

A crane and multi-lifting point technology, applied in cranes, load hanging components, transportation and packaging, etc., can solve the problems of design, manufacture, installation, debugging difficulties, etc., and achieve light weight, huge social benefits, and large bearing capacity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Now in conjunction with the 20000t * 125m hook type bridge crane project, the present invention is further specified

[0040] described as follows:

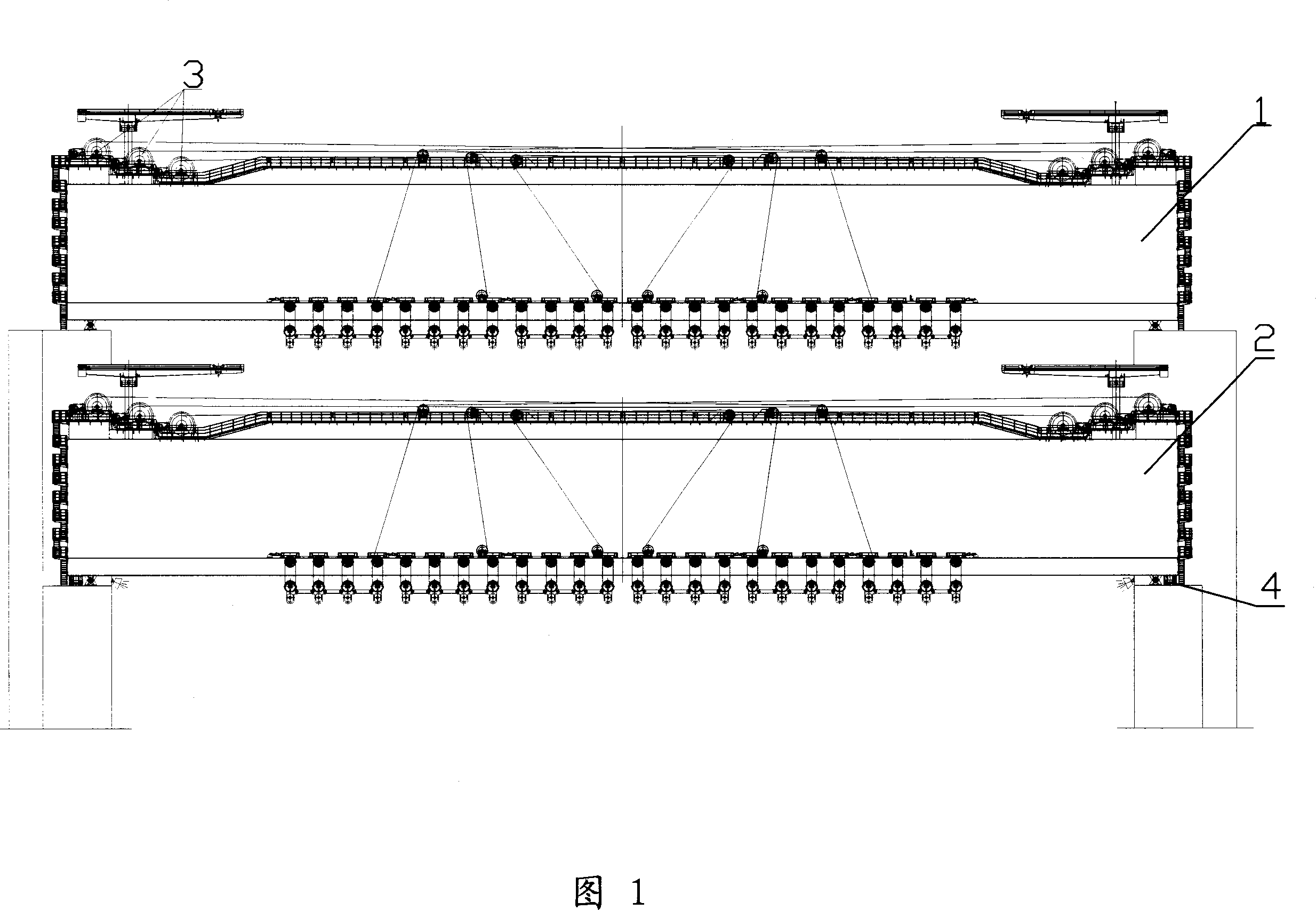

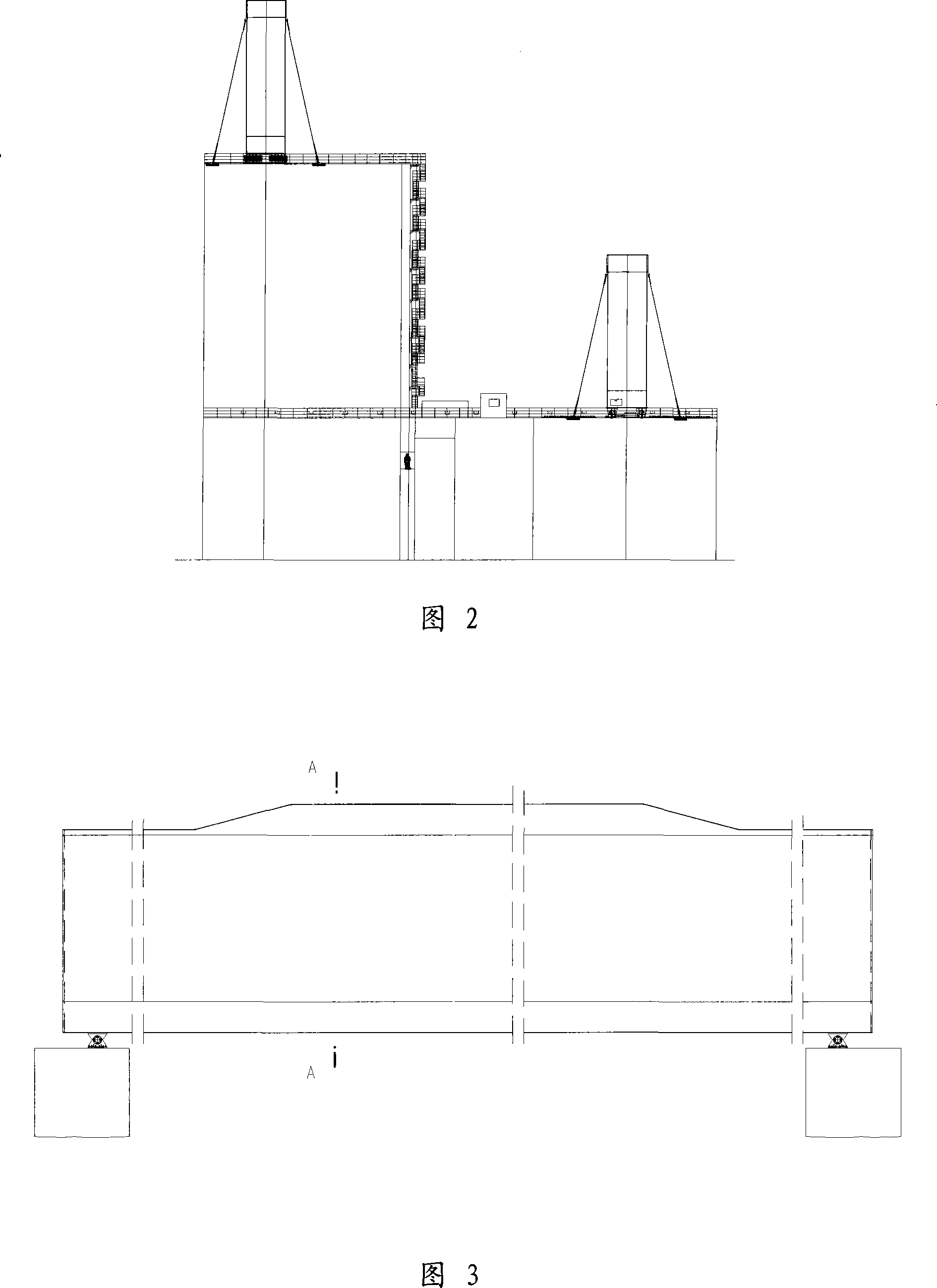

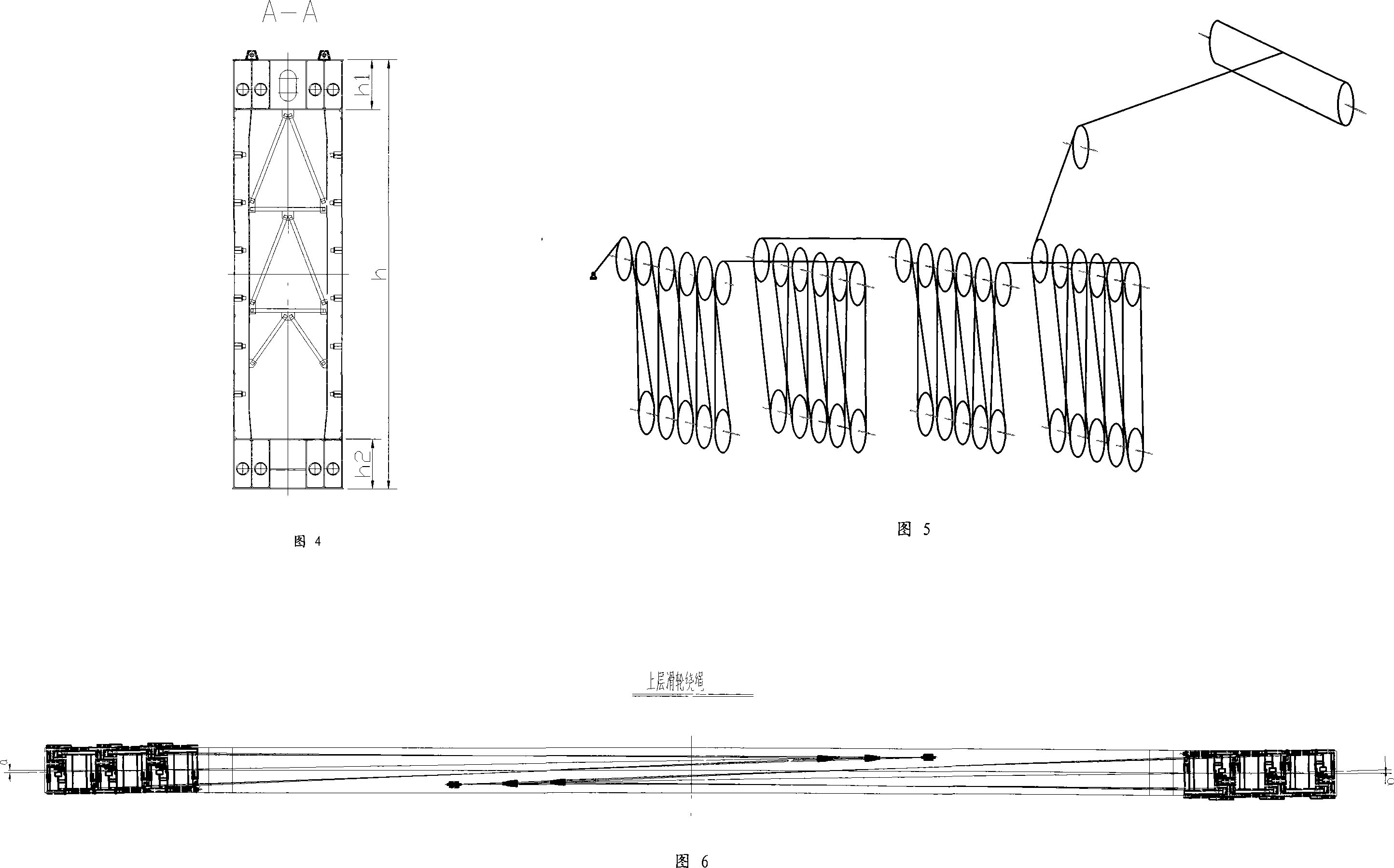

[0041] As shown in Figure 1, the high main girder 1 and the low main girder 2 are respectively arranged on two different concrete foundations. System composition, each hoisting system 3 is composed of hoisting machine, wire rope, guide pulley, fixed pulley block, movable pulley block, etc.; the magnification of the whole system is 40; each hoisting system contains 4 movable pulley blocks, and each movable pulley block controls 1 Lifting Point. The hoist includes reels (including wire rope pressure plates), reducers, brakes, open gears, couplings, floating shafts, bases and other components, that is, the entire mechanism from the coupling connected to the motor to the final brake; The installation of the rope arrangement mechanism can ensure that the entire lifting height does not mess with the rope; the hoist adopts a si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com