Crystallization method for sucrose trichloride

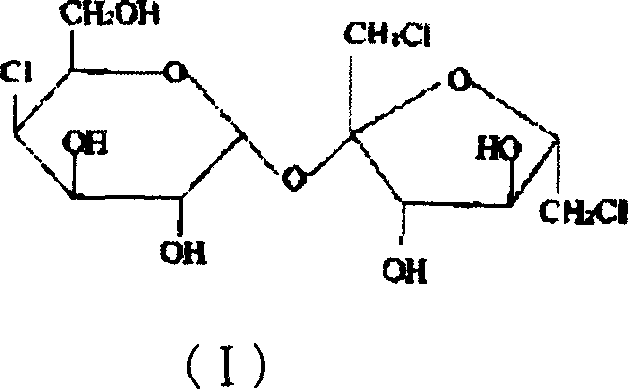

A technology of sucralose and acetyl sucralose, applied in chemical instruments and methods, sugar derivatives, sugar derivatives, etc., can solve the problems of decreased content, poor thermal stability of sucralose crystals, etc., and achieves improved stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

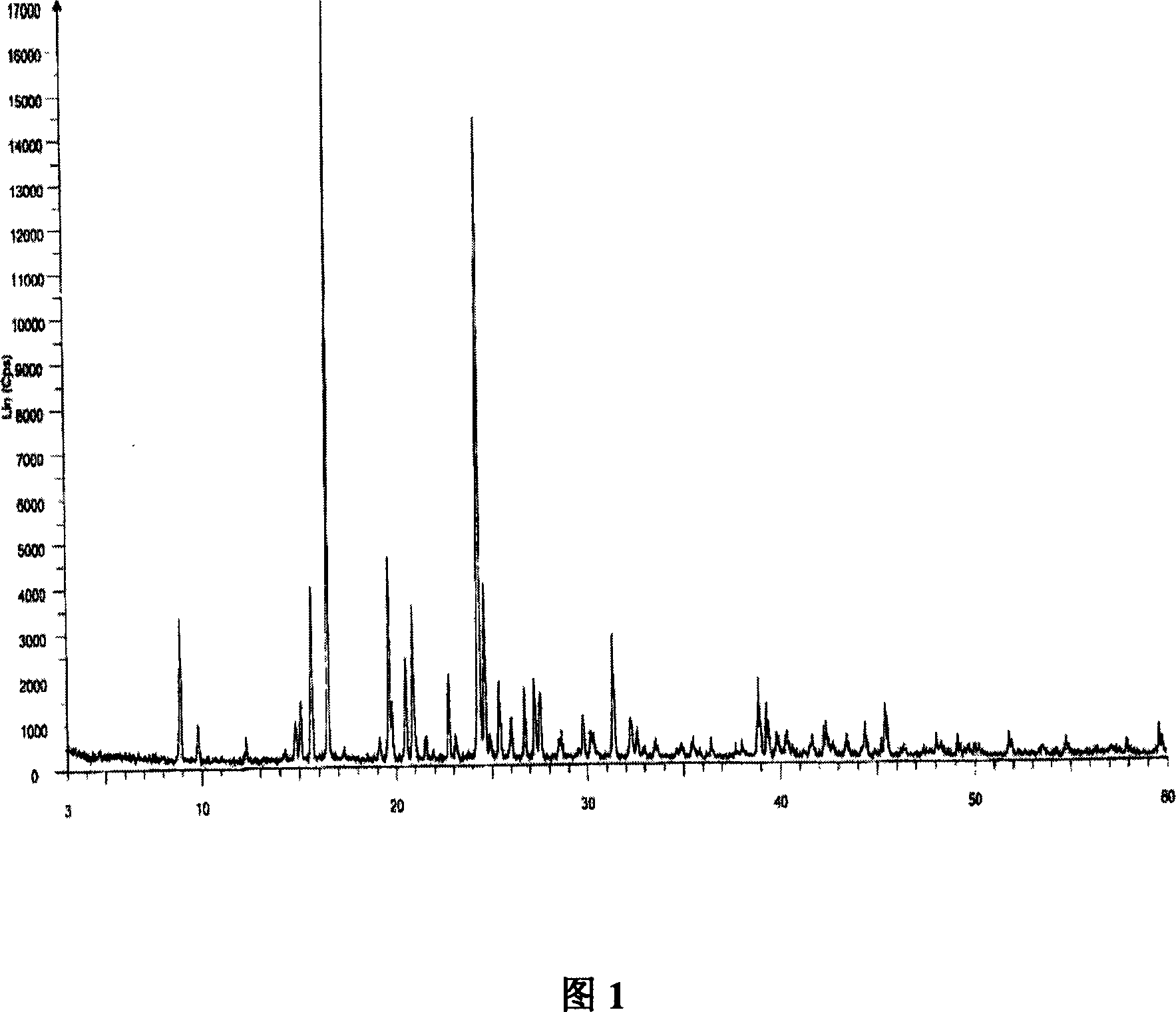

Image

Examples

Embodiment 1

[0022] In a 1000ml three-neck flask, under nitrogen protection, add 100.0g of 2,3,6,3',4'-pentaacetylsucralose with a content of 99.1%, 400.0ml of methanol, and 5.0g of 10% sodium hydroxide in methanol , After reacting at 40-45°C for 1.5-2.0 hours, the cation exchange resin was neutralized to about pH=7.0, the resin was removed by filtration, 5.0 g of activated carbon was added for decolorization, and concentrated to dryness under reduced pressure. Add 400ml of water, concentrate under reduced pressure and distill off residual methanol. Wash once with 50 ml of ethyl acetate, and concentrate the water layer under reduced pressure until the moisture reaches 25.0-30.0%. Stop the concentration, add ethanol to make the ethanol content of the crystallization solution about 5%, heat up to 75°C, cool to 40°C and stir for crystallization for 4 hours, then cool to 30°C and filter. Vacuum dried at 40°C. 42.1 g of sucralose were obtained. HPLC test content reached 98.8%.

Embodiment 2

[0024] In a 1000ml three-neck flask, under nitrogen protection, add 100.0g of 6-acetyl sucralose with a content of 98.5%, 400.0ml of methanol, add 6.0g of sodium hydroxide methanol (10%) solution, and react at 40-45°C for 1.5- After 2.0 hours, the cation exchange resin AMBERLITE IRC86 was neutralized to about pH=7.0, the resin was removed by filtration, 5.0 g of activated carbon was added for decolorization, and concentrated to dryness under reduced pressure. Add 500ml of water, concentrate under reduced pressure and evaporate residual methanol. Wash once with 50 ml of ethyl acetate, and concentrate the water layer under reduced pressure until the moisture reaches 25.0-30.0%. Add ethanol to make the ethanol content of the crystallization solution about 5%, heat up to 75°C, cool to 40°C and stir for crystallization for 4 hours, then cool to 30°C and filter. Vacuum dried at 40°C. 59.5 g of sucralose were obtained. HPLC test content reached 98.9%.

Embodiment 3

[0026] In a 1000ml three-necked flask, under nitrogen protection, add 100.0g of pentaacetylsucralose with a content of 98.5%, 400.0ml of methanol, add 6.0g of sodium hydroxide methanol solution (10%), and react at 40-45°C for 1.5-2.0 Hours later, the cation exchange resin AMBERLITE IRC86 was neutralized to about pH=7.0, the resin was removed by filtration, 5.0 g of activated carbon was added for decolorization, and concentrated to dryness under reduced pressure. Add 400ml of water, concentrate under reduced pressure and distill off residual methanol. Wash once with 50 ml of ethyl acetate, and concentrate the water layer under reduced pressure until the moisture reaches 25.0-30.0%. Stop the concentration, raise the temperature to 75°C, the system dissolves, then cool to 40°C and stir for crystallization for 4 hours, then cool to 30°C, and filter. Vacuum dried at 40°C. 43.1 g of sucralose were obtained. HPLC test content reached 98.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com