Siphon type rainwater discharging system construction technique

A technology of drainage system and construction technology, which is applied in the direction of roof drainage, etc., can solve the problems of large number of rainwater buckets in the system, unfavorable building space requirements, and required slope of horizontal pipes, etc., to save ceiling space, simple construction, and save construction funds Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

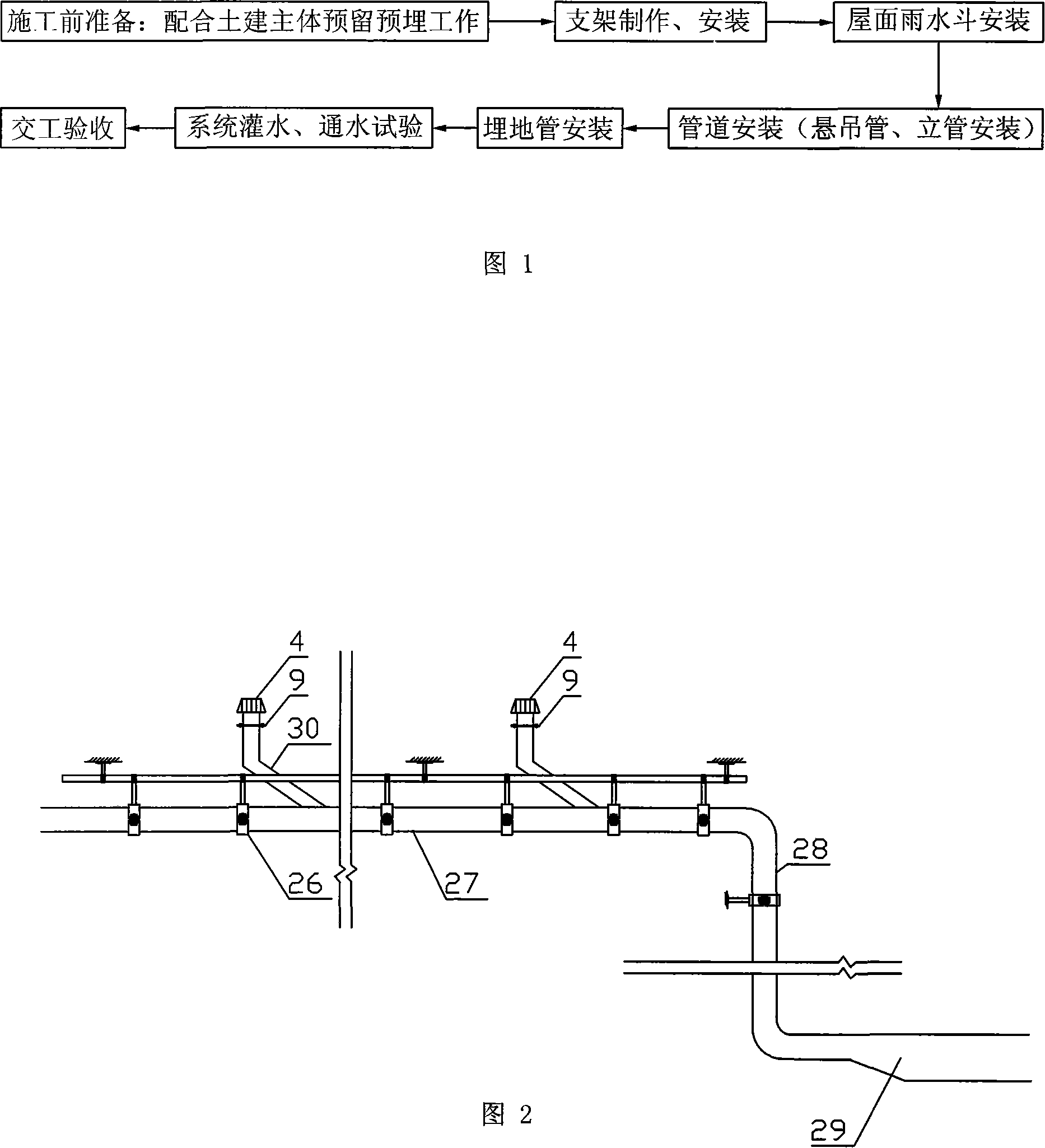

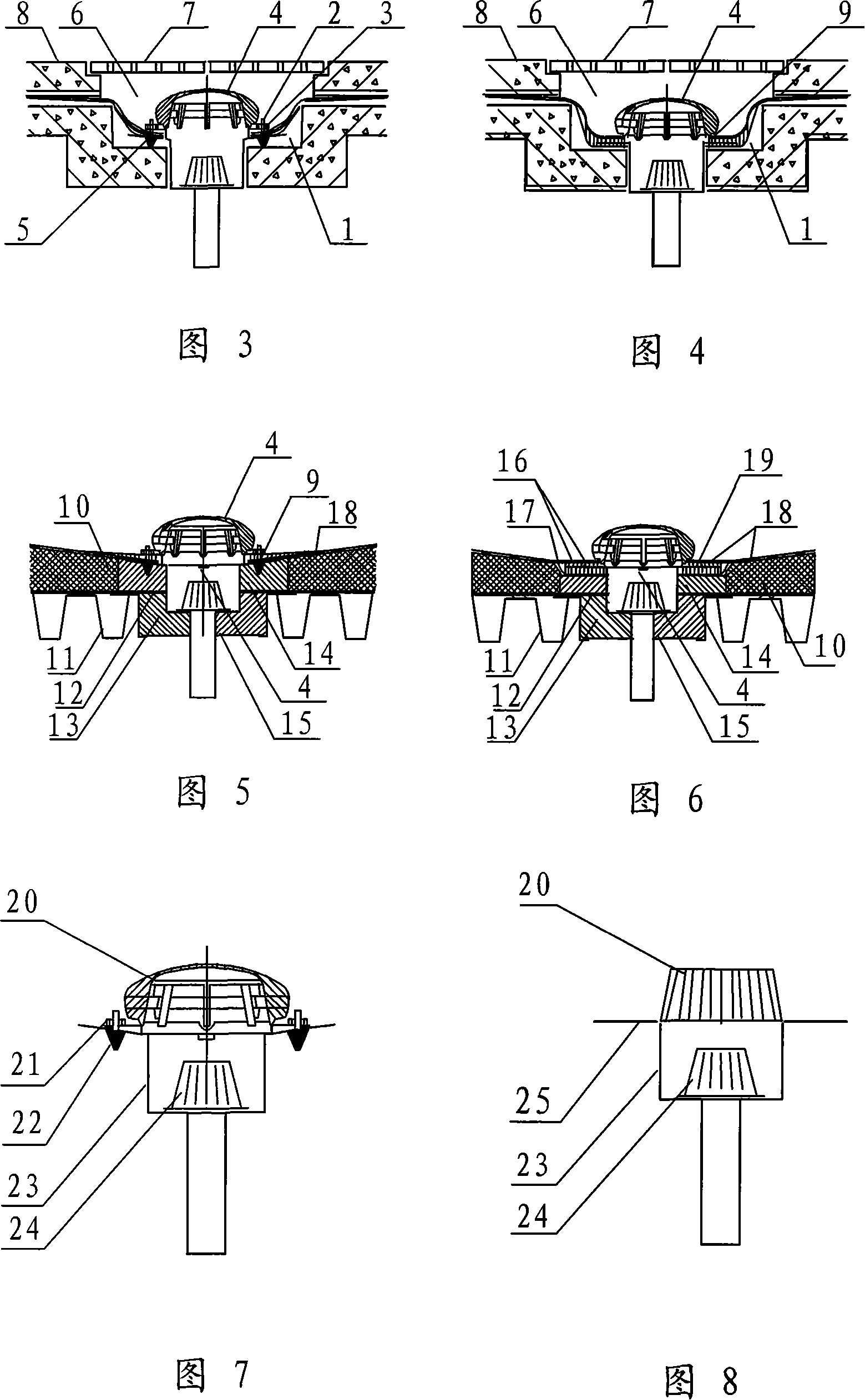

[0015] As shown in Figures 1 and 2, construction preparations need to be made before the construction of the siphon rainwater drainage system using the process of the present invention:

[0016] 1. Carefully review the drawings and reserve holes where the pipes pass through the floors and shear walls. During the construction of the roof structure, it is necessary to reserve a hole suitable for the installation of the rainwater bucket in conjunction with the civil engineering, or directly embed the rainwater bucket seat together with the protective screws in the roof concrete. , accurately determine the position of the reserved hole according to the axis, elevation and water map).

[0017] 2. Bracket production and installation:

[0018] Corresponding pipes are manufactured and installed in accordance with the specifications and design requirements, and attention should be paid to:

[0019] ①. Fixing parts should be installed when the pipeline is installed. The fixing parts m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com