Magnetron control method, magnetron service life judgment method, microwave generation device, magnetron service life judgment device, processing device, computer program, and storage medium

一种微波发生装置、控制方法的技术,应用在微波加热、电热装置、电/磁/电磁加热等方向,能够解决灯丝过加热、磁控管寿命缩短等问题,达到延长寿命的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

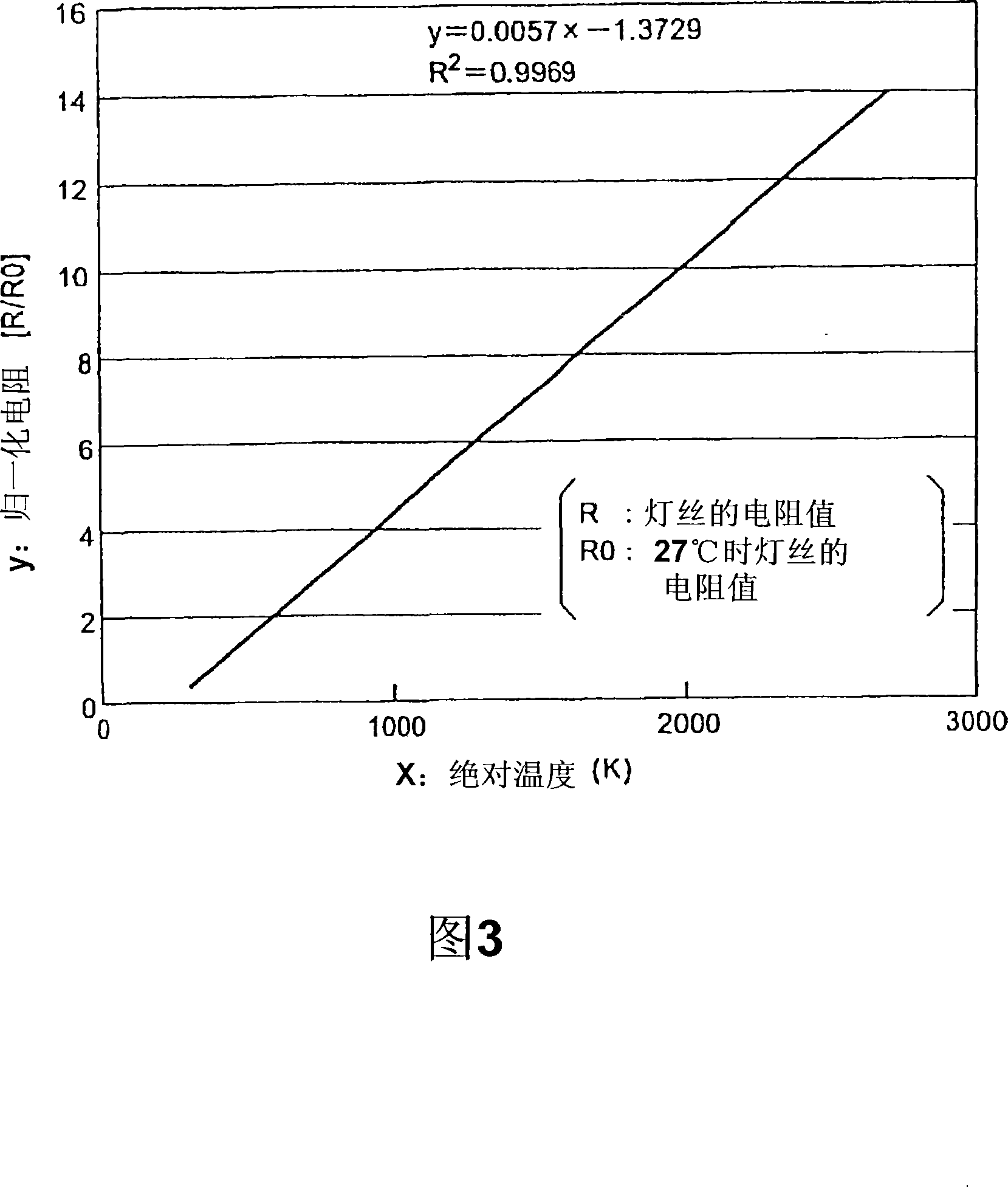

[0043] Hereinafter, an embodiment of a magnetron control method, a magnetron lifetime determination method, a microwave generator, a magnetron lifetime determination device, a processing device, and a storage medium of the present invention will be described with reference to the accompanying drawings.

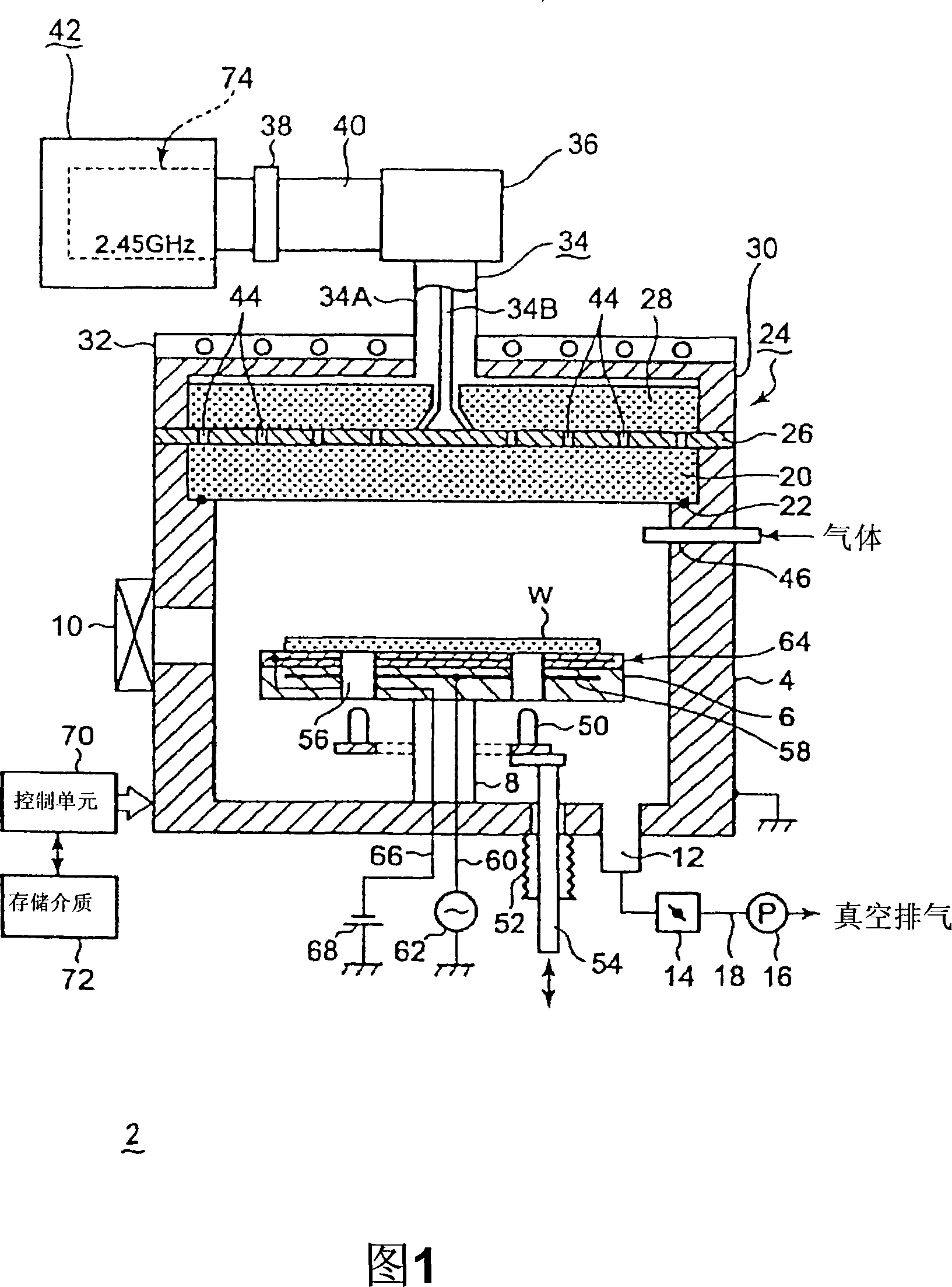

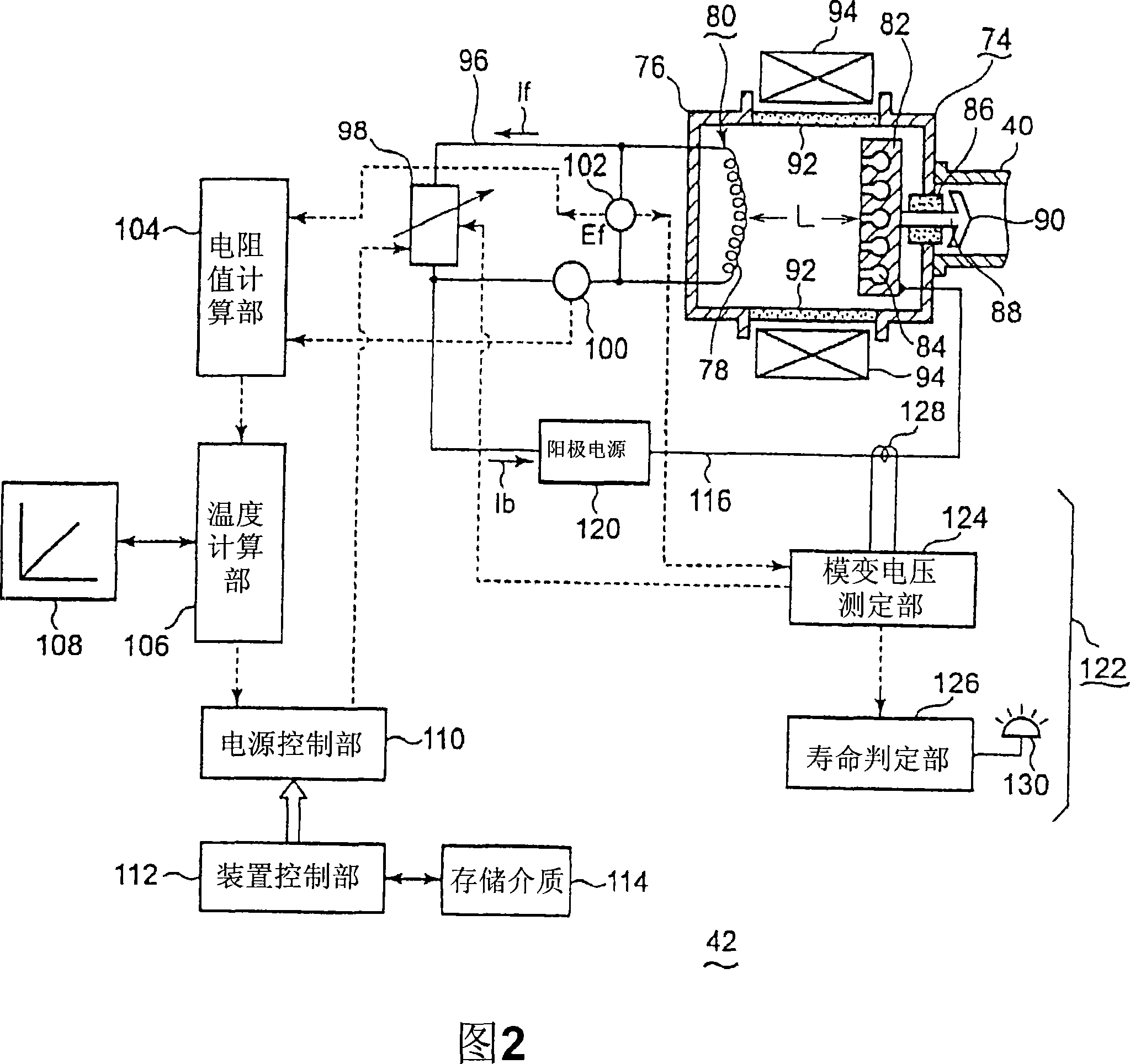

[0044] FIG. 1 is a configuration diagram of an example of a processing device using the microwave generator of the present invention. Figure 2 is a block diagram of the microwave generator. Here, a case where a processing apparatus performs etching using plasma generated by microwaves will be described as an example.

[0045] As shown in the figure, this processing apparatus 2 using plasma has, for example, a side wall and a bottom made of a conductor such as aluminum, and has a cylindrical processing container 4 as a whole. The inside of the processing container 4 is configured as a closed processing space, and plasma is formed in the processing space. The processing contai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com