Application of expanded cabo particle in cigarette filter tip

A technology for expanding tobacco stems and cigarette filters, which is applied in the fields of application, tobacco, tobacco preparation, etc., can solve the problems of loss of tobacco leaf raw materials, health hazards of smokers, increase of downtime accidents, etc., and achieves convenient and feasible operation, low production cost, and increased economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

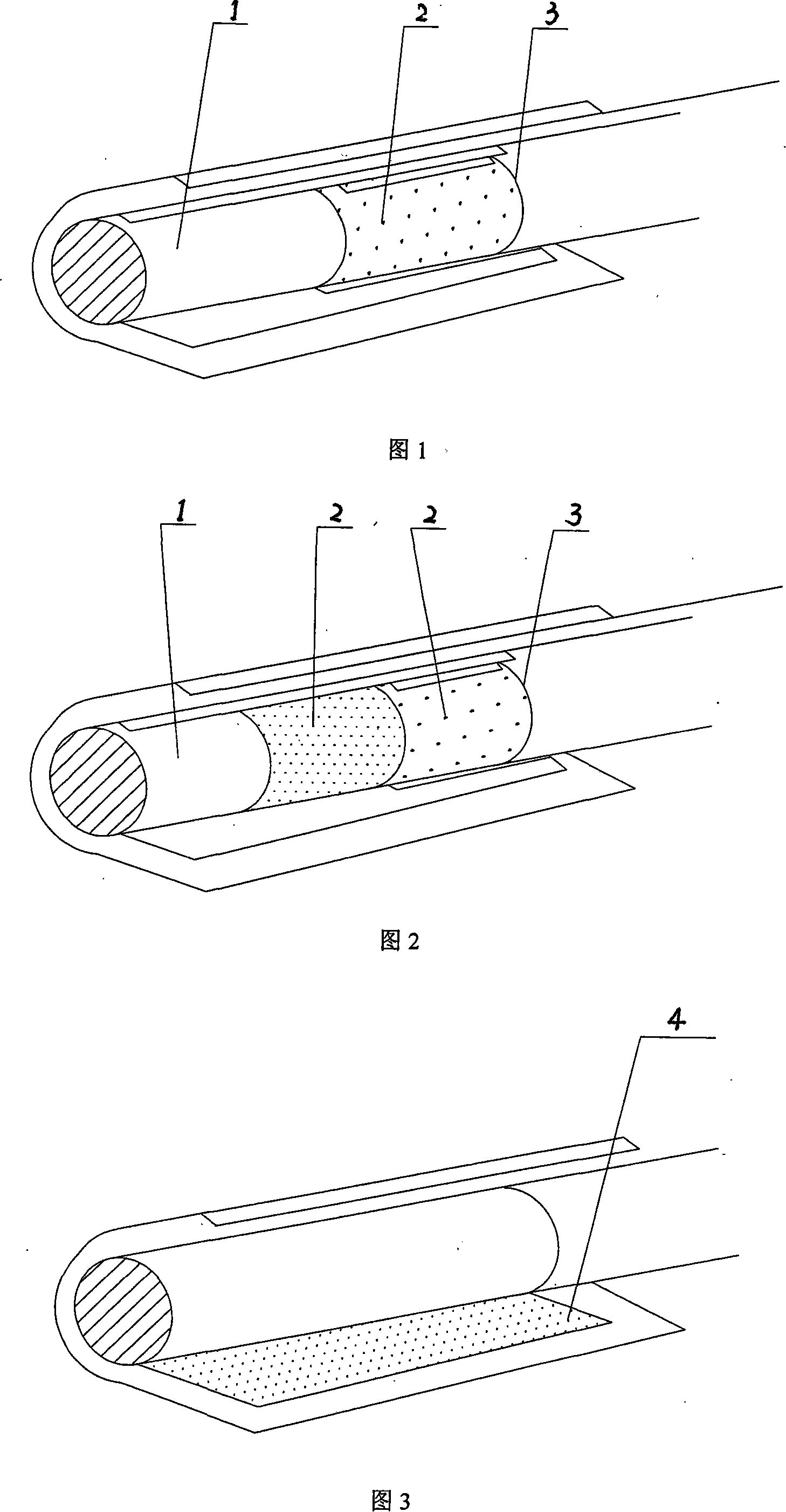

[0039]As shown in FIG. 1 , the fine particles produced during the production of the expanded tobacco stem particles are ground and screened, and the expanded tobacco stem particles 2 with a particle size of 20 meshes are selected and added to the cigarette filter. The addition plan is to evenly sprinkle the ternary porous particles on the acetate tow in an amount of 4mg / 10mm before the filter tow is formed, so as to obtain the composite granule acetate rod 3, and intercept and compound Granular cellulose acetate stick 3 and ordinary cellulose acetate stick 1, the ordinary cellulose acetate stick and composite granular cellulose acetate stick are compounded to obtain a binary composite filter tip. Applying the binary compound filter rod to cigarettes has no negative impact on the sensory quality of the cigarettes, and reduces tar by 10% and nicotine by 5% year-on-year.

Embodiment 2

[0041] Repeat Example 1, with the following differences: the expanded tobacco stem particles with a particle size of 40 meshes are selected and added to the filter polypropylene tow in an amount of 12mg / 10mm polypropylene tow. The prepared binary composite filter rod is applied to cigarettes, making the cigarette aroma clearer and softer, reducing tar by 25% and nicotine by 12% year-on-year.

Embodiment 3

[0043] Repeat Example 1, with the following differences: select the expanded tobacco stem particles with a particle size of 80 mesh and add them to the filter paper core filter material, and the addition amount is 30mg / 10mm paper core. The prepared binary compound filter rod is applied to cigarettes, which makes the cigarette aroma clearer and mellower, and the comfort is significantly improved, and the tar is reduced by 48% and the nicotine is reduced by 16% compared with the same period of last year.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com