Method for measuring number of fine particles in ultrapure water, filtration device for measuring number of fine particles, method for manufacture thereof and hollow fiber film unit for use in the dev

A measuring method and technology of filtering device, applied in the direction of measuring device, dispersed particle filtration, ultrafiltration, etc., can solve the problems of expensive device, polluted particles, complexity, etc., and achieve the effect of shortening filtration time, improving analysis accuracy, and simplifying filtration time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

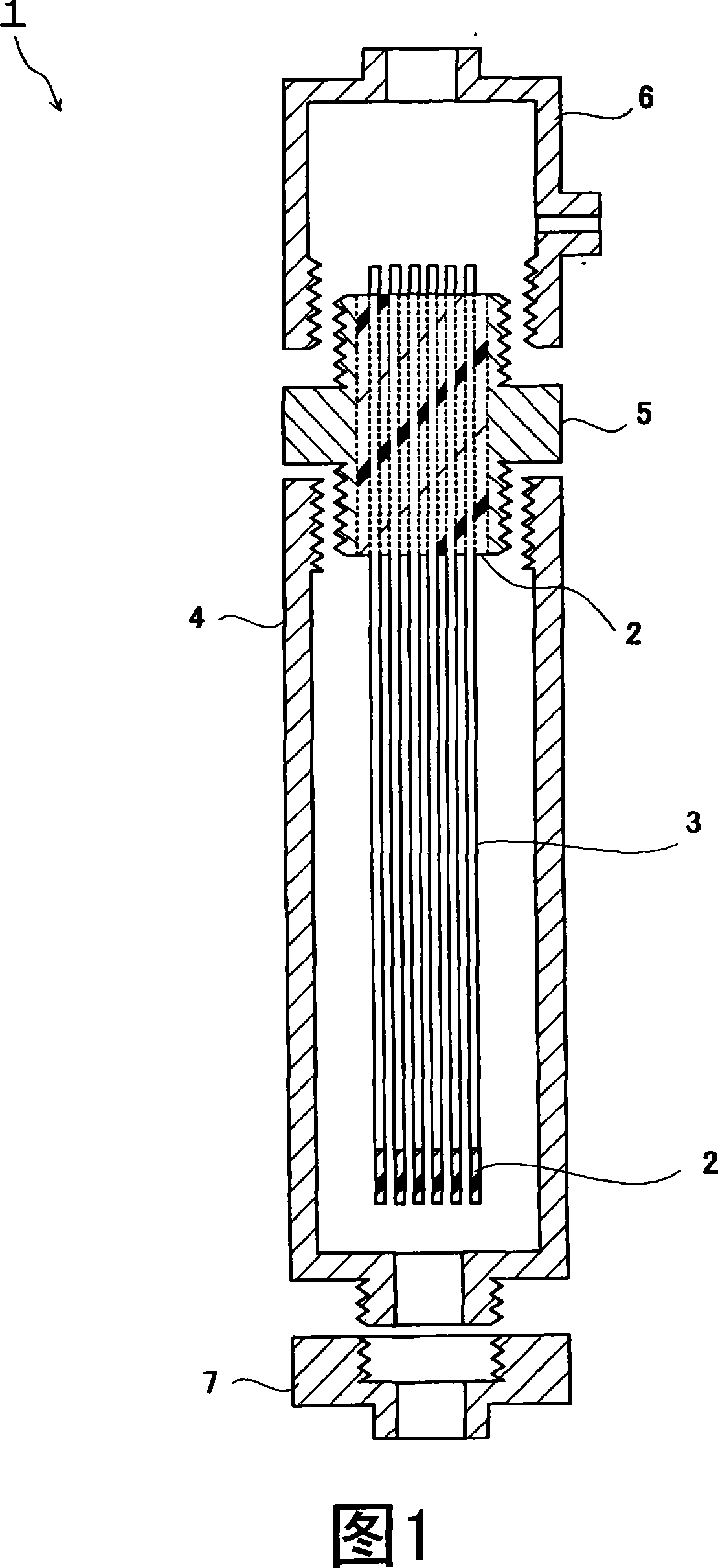

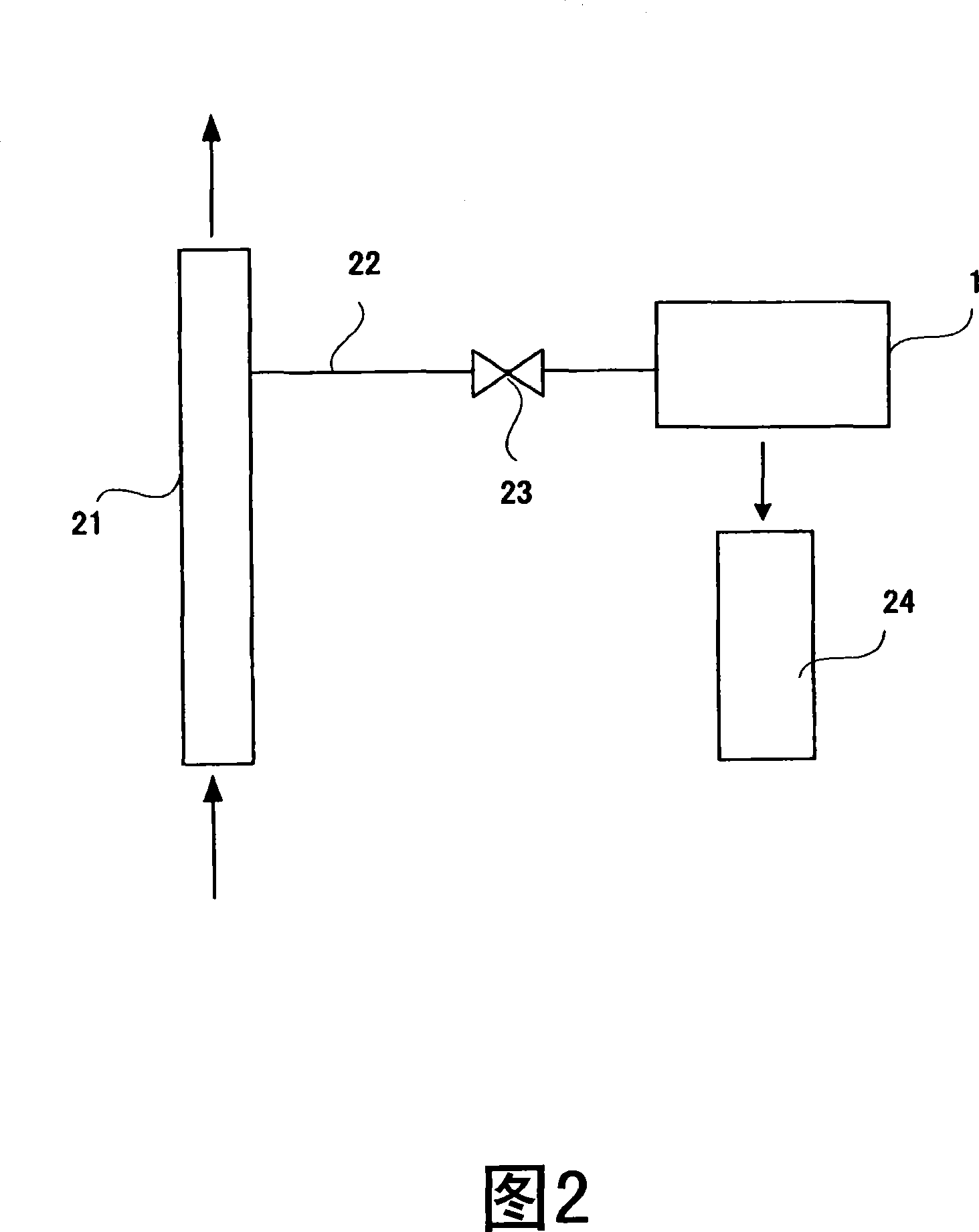

[0040] Next, a first embodiment of the present invention will be described with reference to Fig. 1 and Fig. 2 . Fig. 1 is a cross-sectional view showing the structure of a filter device for measuring the number of fine particles according to a first embodiment. FIG. 2 is a schematic view showing an example of a method for measuring the number of particles in ultrapure water using the filter device for measuring the number of particles shown in FIG. 1 .

[0041] As shown in Fig. 1, the filter device 1 for measuring the number of particles is manufactured by fixing a hollow fiber membrane 3 with one end closed with an adhesive 2 such as epoxy resin to a pipe joint through the adhesive 2 (resin mold part). 5 and other fixed members, and connect the outer cylinder 6 of the water supply part to one side of the pipe joint 5 (the opening end side of the hollow fiber membrane 3), and connect the outer cylinder 4 (support frame) of the drainage part to the other side (the open end sid...

no. 2 Embodiment approach

[0057] Next, a second embodiment of the present invention will be described.

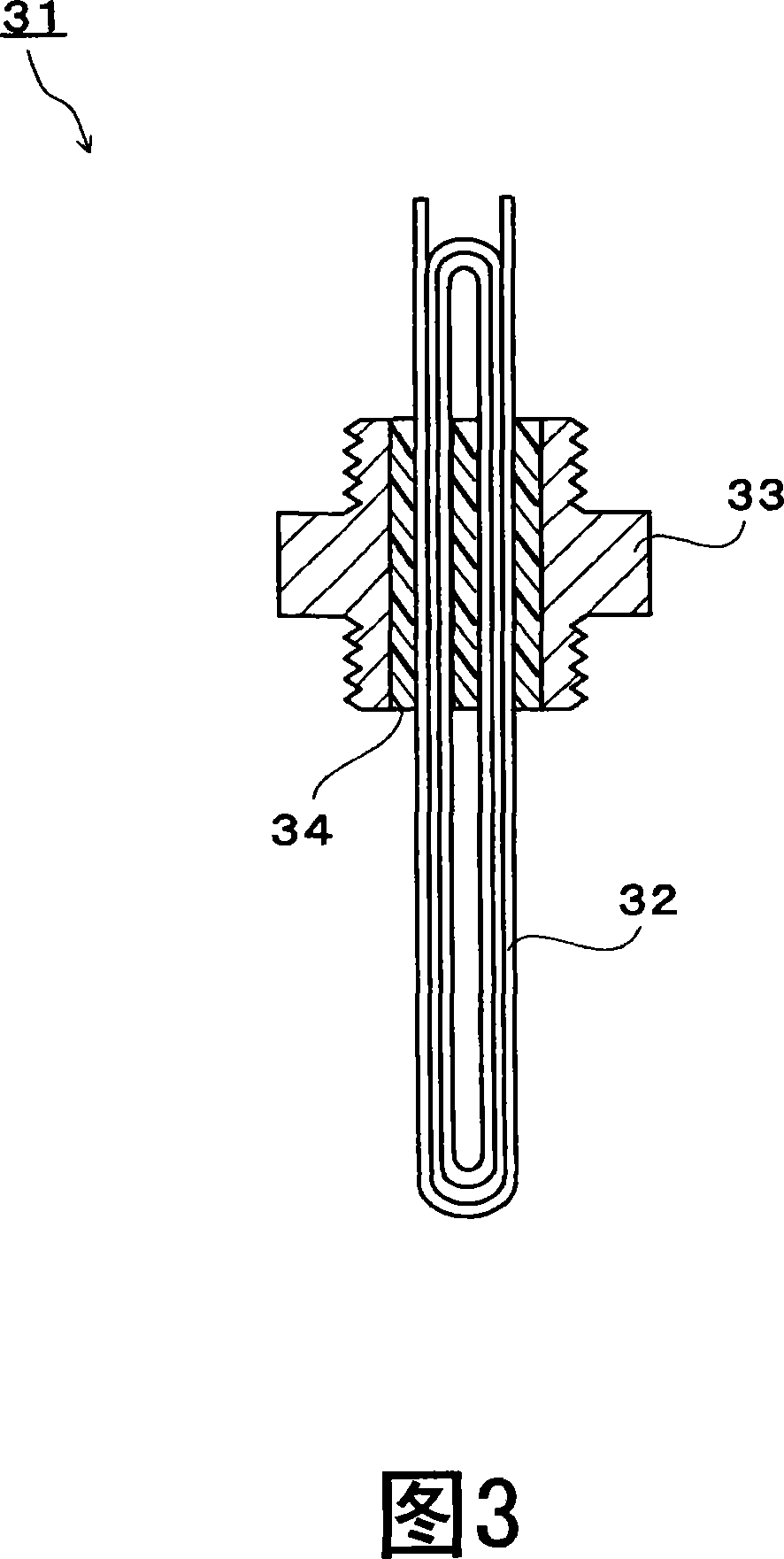

[0058] The filter device for particle number measurement is a hollow fiber membrane module having a hollow fiber membrane unit, wherein the hollow fiber membrane unit is bonded and fixed in a liquid-tight manner by an adhesive (resin mold part). It is constructed on the disassembled joint (fixed member). Examples of easily detachable joints (fixing members) include commercially available screw joints such as pipe joints, sockets, unions, and sleeves. Depending on the circumstances, it may be a machined product obtained by cutting a round bar or the like to provide an arbitrary screw thread, or a ferrule fitting or the like. The material of the joint (fixing member) depends on the sampling point, and examples thereof include plastics such as stainless steel, polyvinyl chloride resin, polyvinylidene fluoride resin, polyethylene resin, and polypropylene resin. In particular, stainless steel, polyviny...

no. 3 Embodiment approach

[0064] Next, a third embodiment of the present invention will be described with reference to FIG. 4 . Fig. 4 is a cross-sectional view showing the structure of a hollow fiber membrane unit used in a filter device for measuring the number of fine particles according to a third embodiment.

[0065] The hollow fiber membrane unit 201 has a hollow fiber membrane 203 whose both ends are sealed with a sealing resin 202 (adhesive). In addition, the hollow fiber membrane unit 201 is bonded and fixed to a fixing member such as a pipe joint 204 with an adhesive 205 (resin mold part) such as epoxy resin in a state where the closed portions at both ends are exposed. In this way, by sealing both ends of the hollow fiber membrane 203 with the sealing resin 202 or the like in advance, it is possible to keep the inner surface, which is the surface for capturing fine particles, clean until the time of use. In addition, the number of hollow fiber membranes 203 is not particularly limited, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com