Synthetic method of high-compactness phosphoric-acid-based wave-transmitting material

The technology of a phosphoric acid-based wave-transmitting and synthesis method is applied in the synthesis field of wave-transmitting materials, which can solve problems such as poor sealing, and achieve the effects of good sealing, not easy to break, and simple synthesis method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

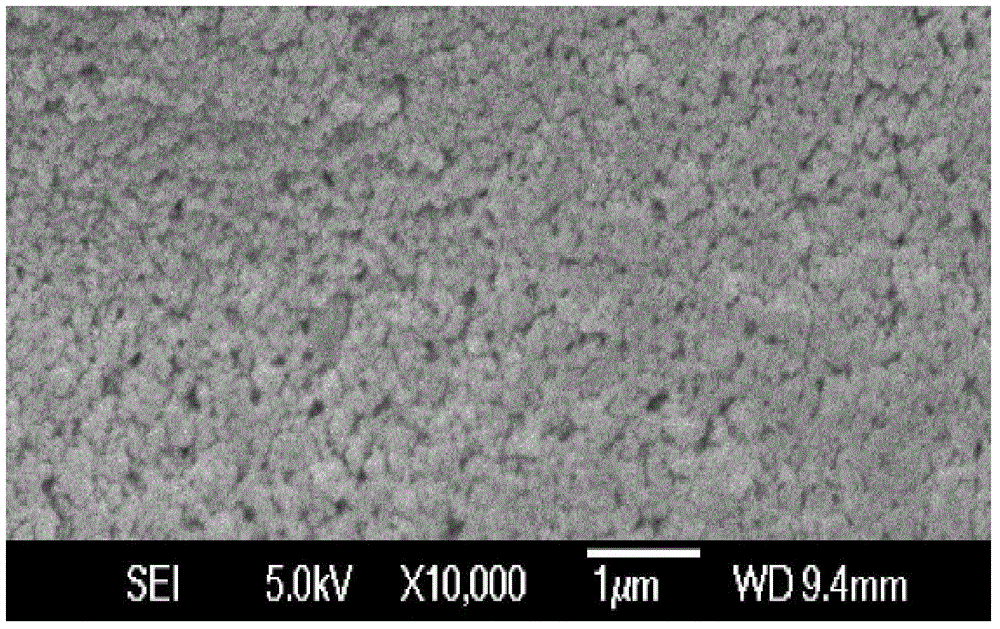

Image

Examples

Embodiment 1

[0019] Weigh 3g of zinc oxide, 10g of aluminum oxide and 5g of zirconia and mix them in beaker 1, place them in an ultrasonic cleaner, weigh 15g of aluminum dihydrogen phosphate solution with a mass fraction of 85% in beaker 2, and place the Add the mixture to beaker 2, then add 2mL of nickel nitrate solution with a concentration of 0.05mol / L and 2mL of ferric chloride solution with a concentration of 0.05mol / L, stir it with a glass rod, and place it in an ultrasonic Ultrasonic mixing is uniform in the cleaner, the ultrasonic frequency is 40KHz, the temperature is controlled at 60-80°C, and the ultrasonic vibration is dispersed for 2 hours. This slurry is used as the precursor of the wave-transparent material.

[0020] Soak the cut quartz fiber cloth with a size of 46mm×102mm in it. During this process, the ultrasonic frequency is changed to 20KHz. After soaking for 12 hours, take it out and calcinate it in a tube furnace. When calcining, the heating rate is 5°C / min. After cal...

Embodiment 2

[0022] Weigh 2g of zinc oxide, 10g of alumina, 3g of silicon dioxide, 5g of zirconia and 3g of titanium dioxide and mix them in beaker 1, place them in an ultrasonic cleaner, weigh 20g of aluminum dihydrogen phosphate solution with a mass fraction of 85% in the beaker In step 2, add the mixture in beaker 1 to beaker 2, then add 2 mL of nickel nitrate solution with a concentration of 0.05 mol / L and 2 mL of ferric chloride solution with a concentration of 0.05 mol / L, and use a glass rod After stirring, place it in an ultrasonic cleaner to mix evenly with ultrasonic waves. The ultrasonic frequency is 40KHz, the temperature is controlled at 60-80°C, and the ultrasonic vibration is dispersed for 2 hours. This slurry is used as a wave-transparent material precursor.

[0023] Soak the cut quartz fiber cloth with a size of 46mm×102mm in it. During this process, the ultrasonic frequency is changed to 20KHz. After soaking for 12 hours, take it out and calcinate it in a tube furnace. When...

Embodiment 3

[0025] Weigh 2g of zinc oxide, 5g of aluminum oxide, 3g of silicon dioxide, 7g of zirconia and 3g of titanium dioxide and mix them in beaker 1, place them in an ultrasonic cleaner, weigh 15g of aluminum dihydrogen phosphate solution with a mass fraction of 85% in the beaker In step 2, add the mixture in beaker 1 to beaker 2, then add 2 mL of nickel nitrate solution with a concentration of 0.05 mol / L and 2 mL of ferric chloride solution with a concentration of 0.05 mol / L, and use a glass rod After stirring, place it in an ultrasonic cleaner to mix evenly with ultrasonic waves. The ultrasonic frequency is 40KHz, the temperature is controlled at 60-80°C, and the ultrasonic vibration is dispersed for 2 hours. This slurry is used as a wave-transparent material precursor.

[0026] Soak the cut quartz fiber cloth with a size of 46mm×102mm in it. During this process, the ultrasonic frequency is changed to 20KHz. After soaking for 12 hours, take it out and calcinate it in a tube furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com