Multilayer composite material fire-extinguished blanket

A multi-layer composite material and fire blanket technology, which is applied in fire rescue and other fields, can solve the problems of poor storage time, damage to the atmospheric ozone layer, and impact on fire extinguishing effects, etc., and achieve the effect of strong practicability, soft texture, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

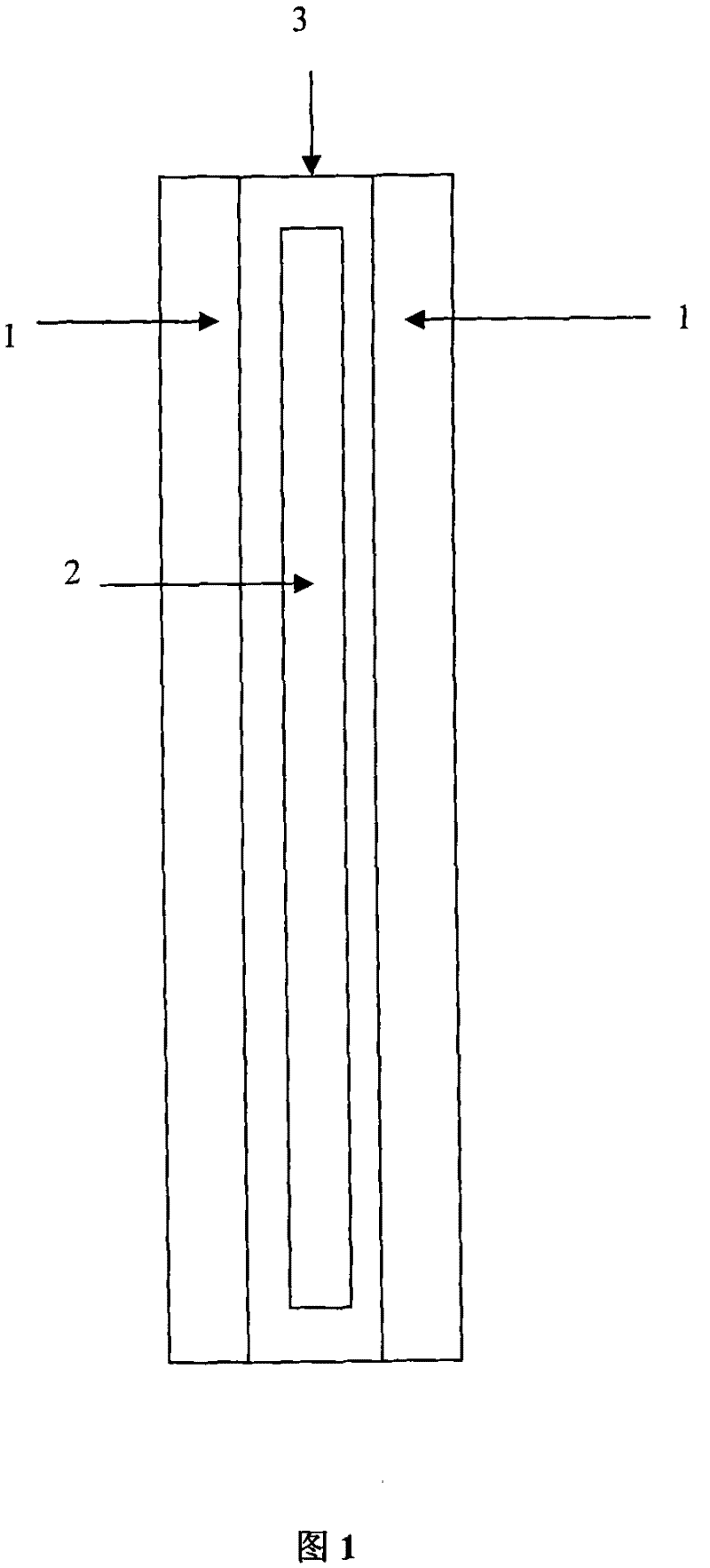

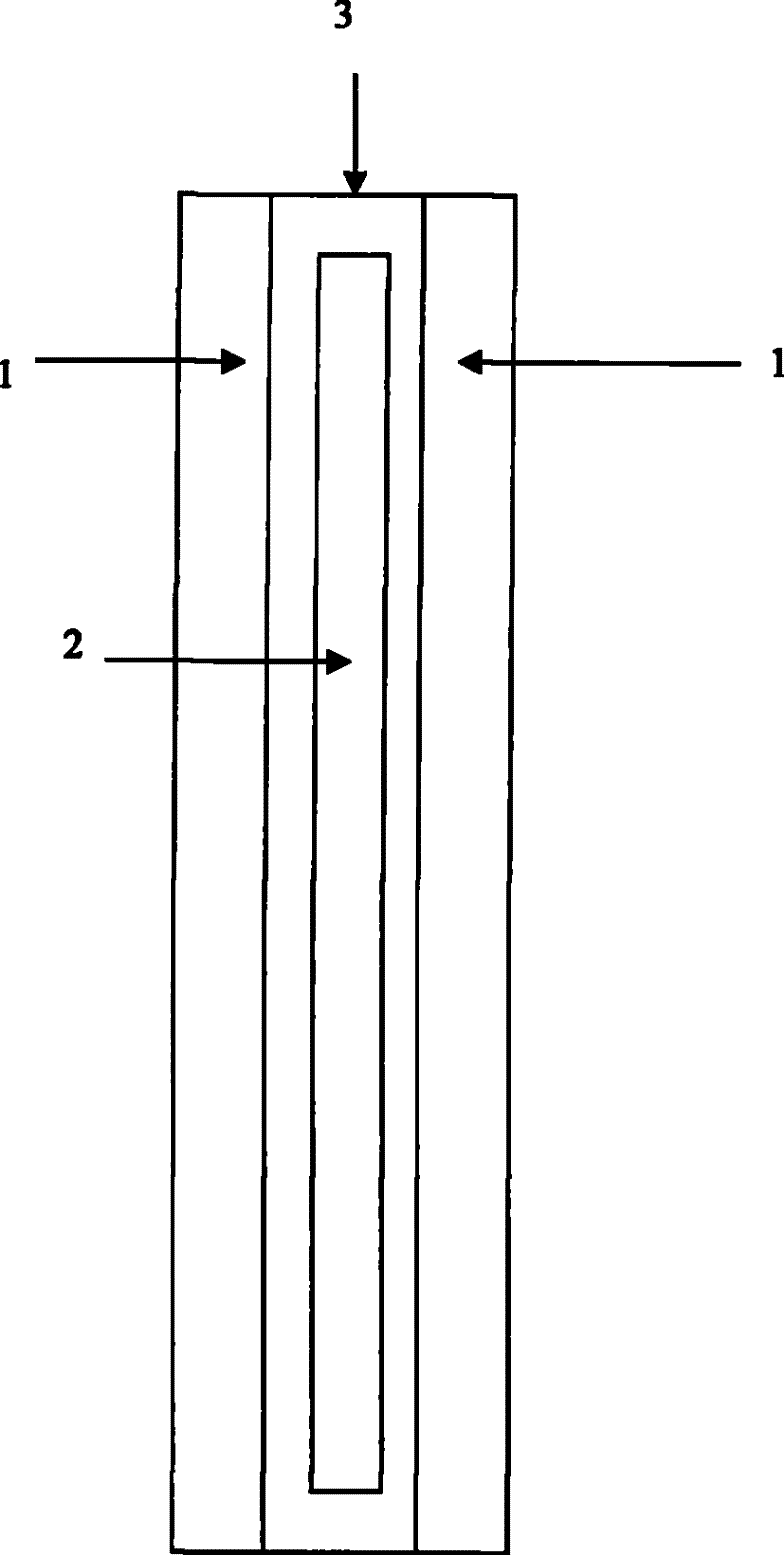

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0028] A multi-layer composite material fire-extinguishing blanket, which is in the shape of a blanket, is made of soft high-silica refractory fiber and fibrous activated carbon filter cloth, and is continuously sewn with 0.3 mm heat-insulating and flame-retardant tweezers on the four sides; The high-silica glass fiber and the fibrous activated carbon filter cloth are all high-performance high-temperature resistant inorganic composite fibers, and the main component of the high-silica glass fiber is silicon dioxide (SiO 2 ). The silicon dioxide (SiO 2 ) content is higher than or equal to 96%, the softening point is close to 1700°C, and it can be used for a long time at 900°C. The maximum operating temperature of the fibrous activated carbon filter cloth is 1000°C, which can reach the ignition point of air above 500°C, and at the same time, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com