Electric-controlled injection carburettor

An electronically controlled injection and carburetor technology, applied in fuel injection devices, machines/engines, engine components, etc., can solve problems such as destroying ecological balance, high engine emissions, and affecting the environment, achieving high-precision supply, prolonging service life, The effect of precise supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

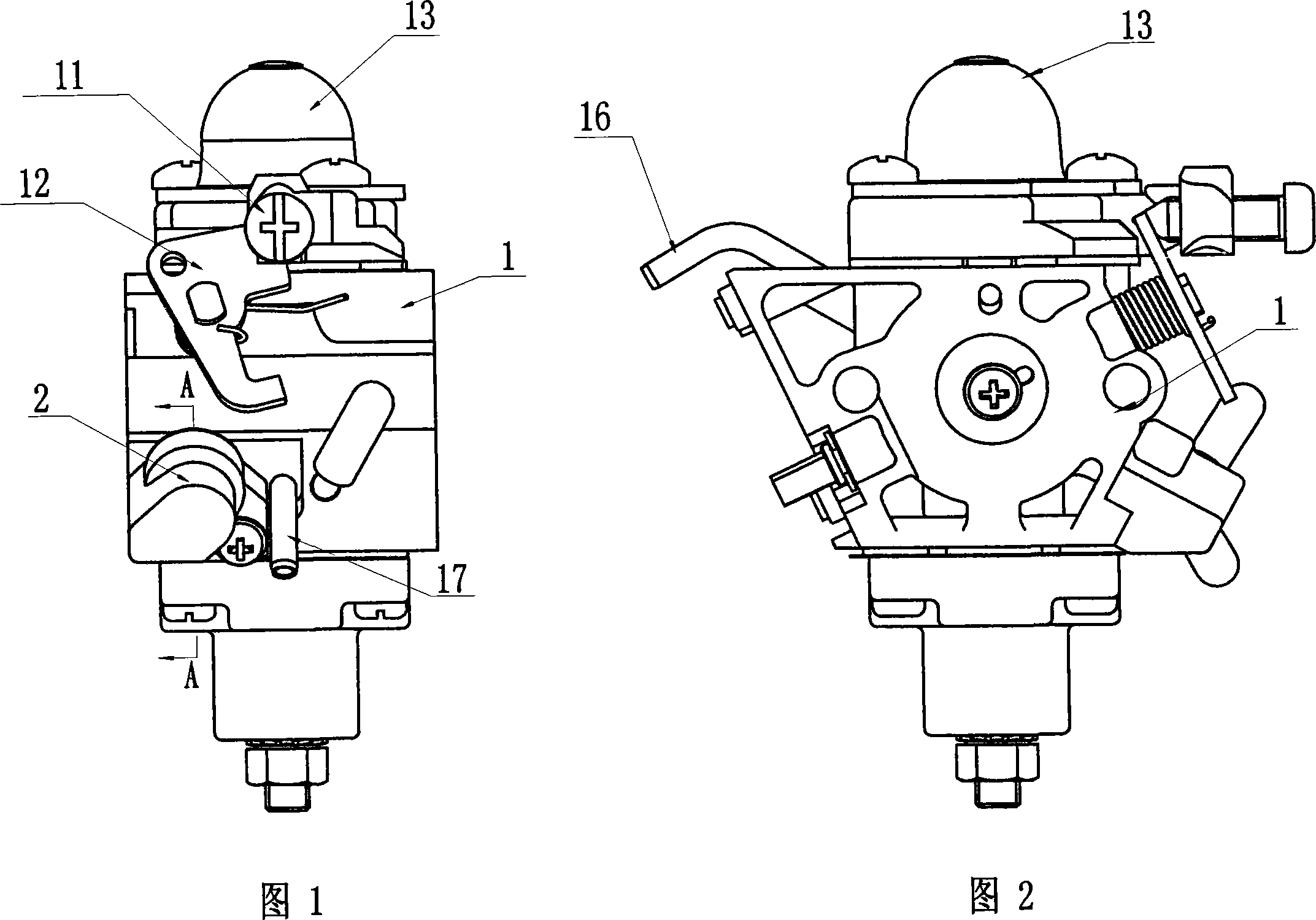

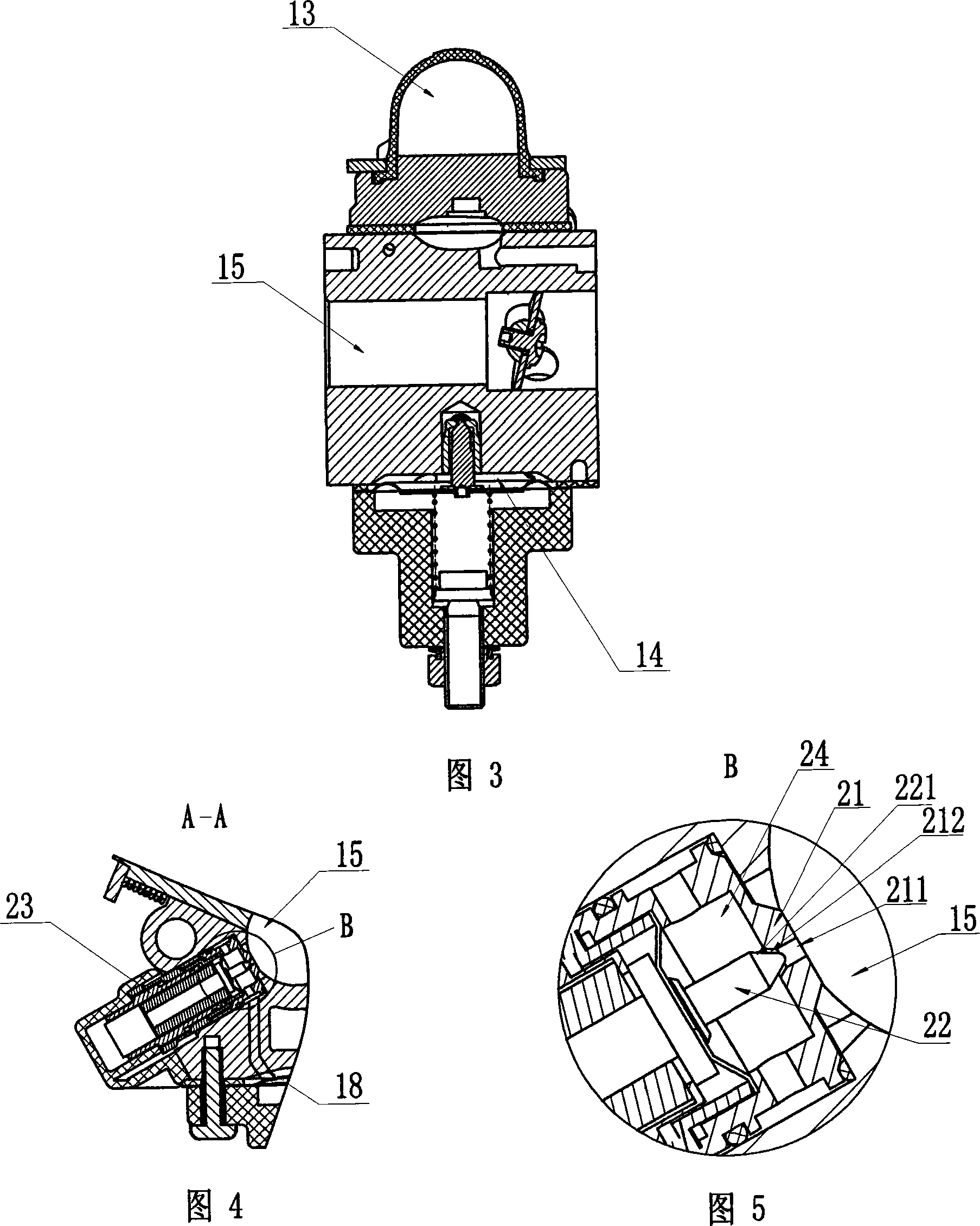

[0014] As shown in Fig. 1, Fig. 2, Fig. 3, Fig. 4 and Fig. 5, an electronically controlled injection carburetor includes a carburetor body 1 and a throttle adjusting screw 11 and a throttle shaft member 12 arranged on the carburetor body 1 , oil cup 13, oil storage chamber 14, throat pipe 15, oil inlet pipe 16 and oil return pipe 17, in the embodiment of the present invention, the channel 18 of the oil inlet pipe 16 and throat pipe 15 is provided with a The electromagnetic valve electronically controlled injection device 2, the electromagnetic valve electronically controlled injection device 2 includes a fuel injector 21, one end of which cooperates with the fuel injector 21 to control the fuel output. The other end of the ejector rod 22 is provided with a control ejector A magnetic induction mechanism 23 for telescoping the rod 22 . The fuel injector 21 is located at the top of the solenoid valve electronically controlled injection device 2, and its fuel injector 211 is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com