Flow quantity self-adjusting jetting stream vacuum generator

A vacuum generator and vacuum generation technology, which is applied in jet pumps, non-displacement pumps, machines/engines, etc., can solve problems such as inability to adapt to complex working conditions, increase user costs, and inability to adjust the flow rate of vacuum nozzles, etc., to achieve reduction Small effective cross-sectional area, automatic adjustment, and reduced air consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

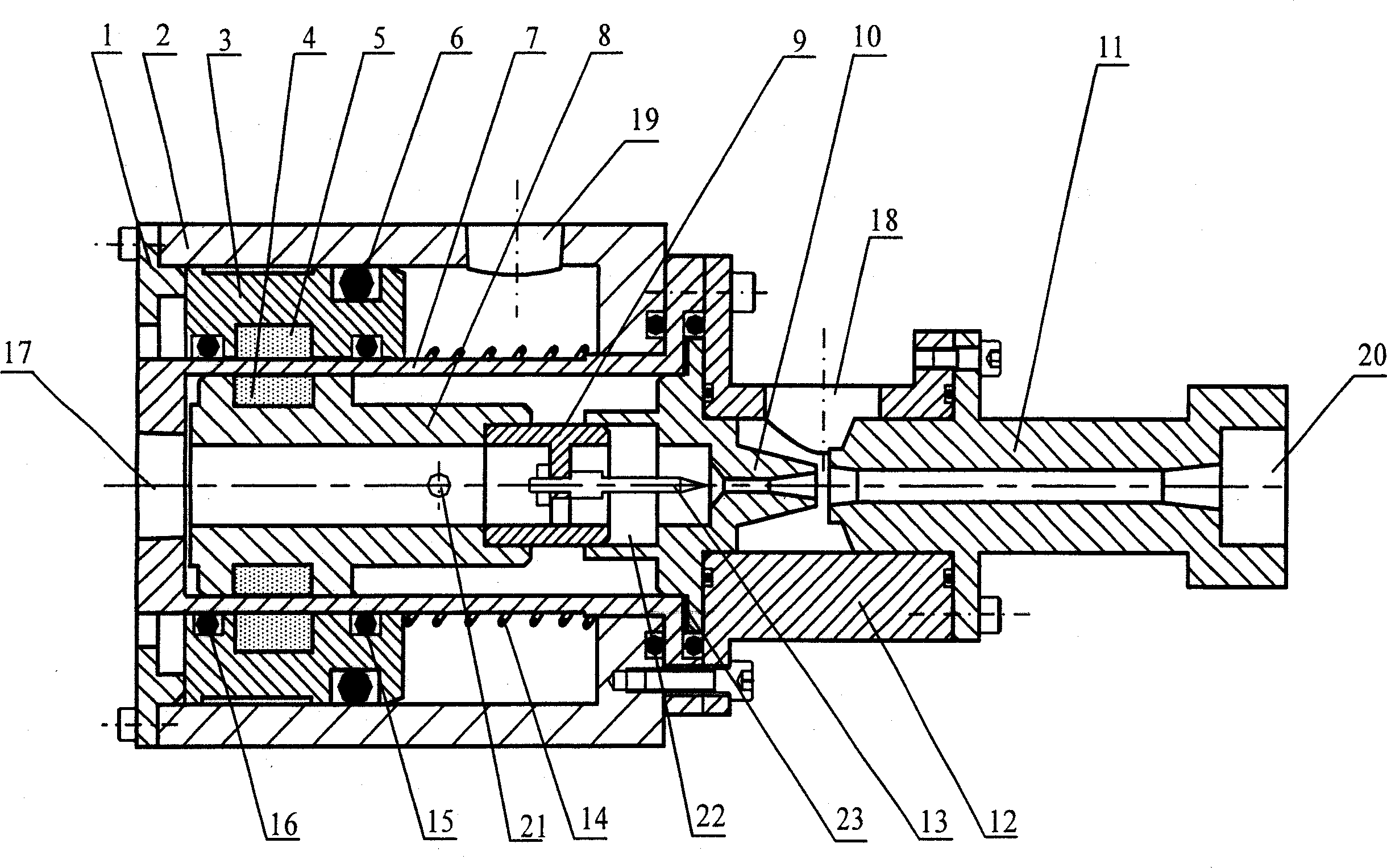

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0010] With reference to the accompanying drawings, the flow self-regulating jet vacuum generator of the present invention includes a flow self-regulating part and a vacuum generating part, and the flow self-regulating part is located at the front end of the vacuum generating part. Wherein, the vacuum generating part includes a nozzle 10, a receiving pipe 11 and a connecting pipe 12 connecting the nozzle 10 and the receiving pipe 11. The connecting pipe 12 is provided with a vacuum port 18 that can be connected with a vacuum suction cup. The nozzle 10 and the receiving pipe The tube 11 constitutes the gas flow passage of the vacuum generating portion, and the inner walls of the nozzle 10, the receiving pipe 11 and the connecting pipe 12 constitute a vacuum chamber. The flow self-regulating part includes a master cylinder and a slave cylinder. The master cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com