Method for preparing D-amino acid by biological catalysis

A biocatalysis and amino acid technology, applied in the field of compound preparation, can solve the problems of various types of emissions, complex process, high price, etc., and achieve the effects of controlling enantiomeric purity, simple steps and short routes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1D

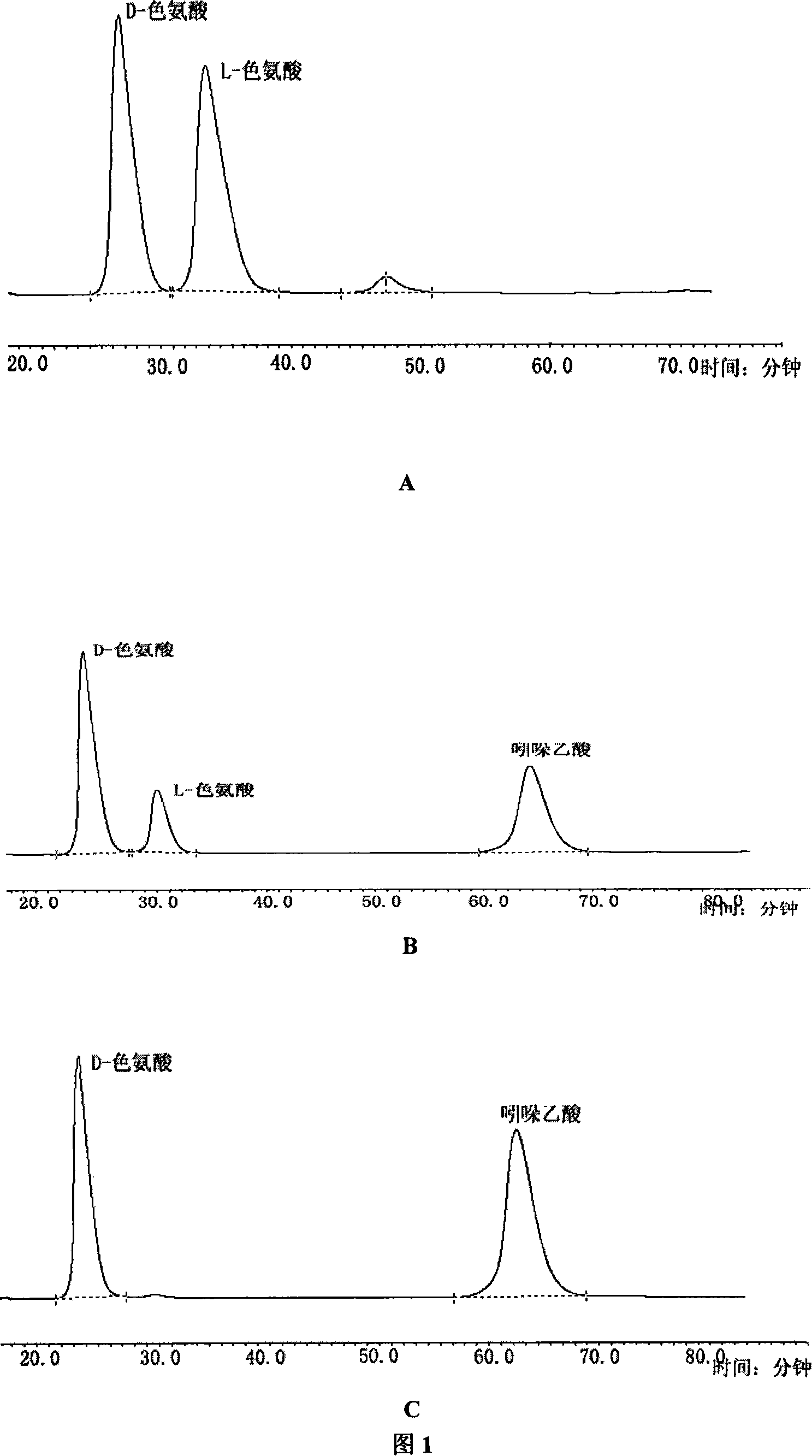

[0019] The preparation of embodiment 1D-tryptophan and indole acetic acid

[0020] In a 500mL shake flask (in 28 flasks at the same time), culture yeast Rhodotorulagraminis (ATCC 20804) (Rhodotorula pasture), grow for 24 hours, centrifuge, pour out the supernatant, freeze, ultrasonically break the wall, and make a homogenate , put it back into the shaker flask, add the same amount of racemate D, 50 mg of L-tryptophan to each bottle; adjust the pH to 7.3, ventilate the air, seal it with ventilation, put it back in the temperature-controlled shaker, and shake it in a circular manner. Take one milliliter sample for analysis at 0 hour, 6 hours and 12 hours, track the progress of the reaction, ultrafilter, dilute, inject into HPLC for tracking analysis, use Daiselu crown ether column, Crownpak CR(+), D-Try , tr=22min, L-Try, tr=30min. The analysis time was extended to 120 minutes. The results are shown in Figure 1, which shows the change process of the amount of each substance in ...

Embodiment 2

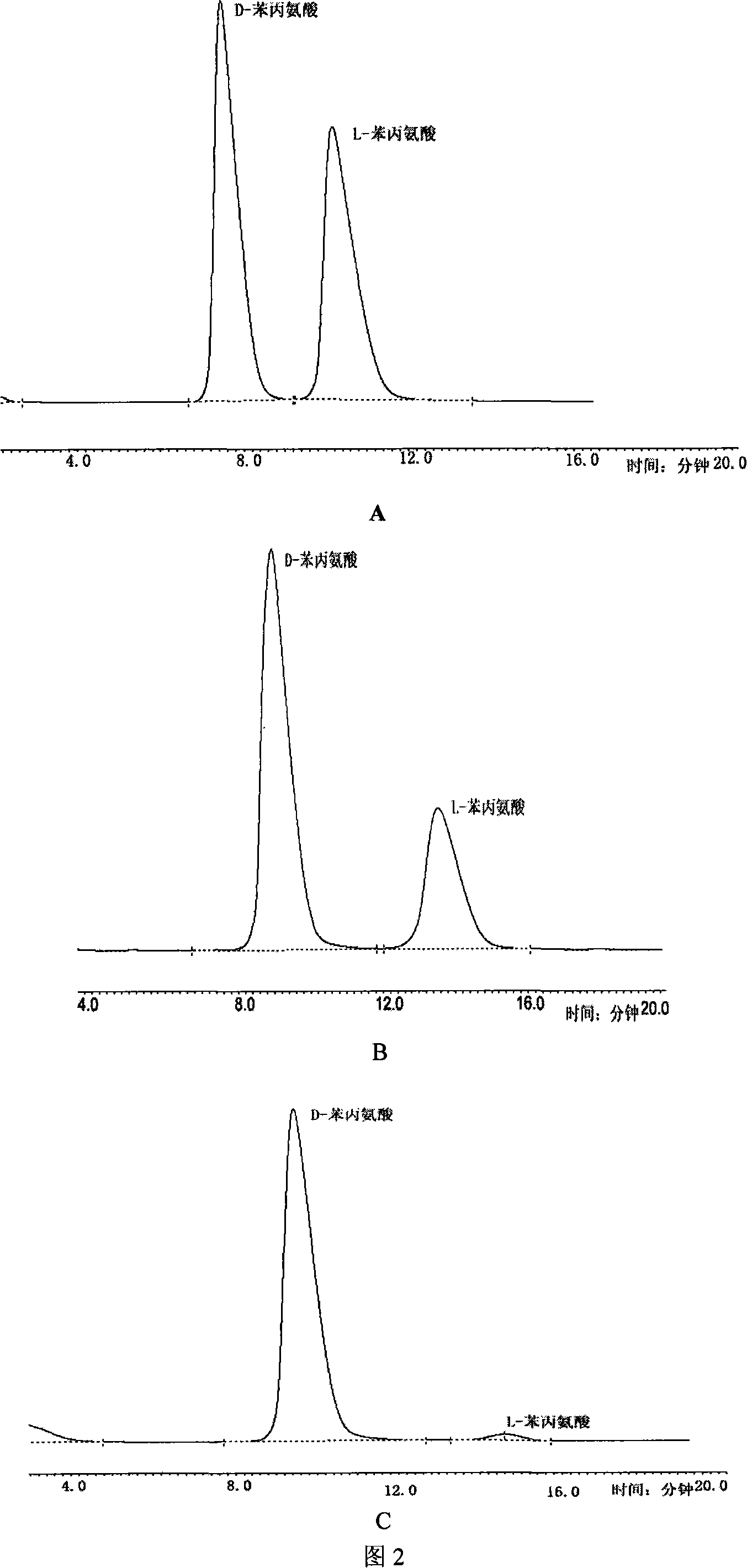

[0022] The preparation of embodiment 2D-phenylalanine

[0023] In a 500mL shake flask, culture yeast Rhodotorula graminis (ATCC 20804) (Rhodotorula grass), grow for 24 hours, centrifuge, pour out the supernatant, freeze, ultrasonically break the wall, make a homogenate, divide evenly and shake back In the bottle, add the same amount of racemate D, 50 mg of L-phenylalanine to each bottle; adjust the pH to 7.3, ventilate the air, put it back in the temperature-controlled shaker, shake it circularly, and take out one milliliter of the sample periodically for Analysis, tracking the reaction process, in the reaction of 4h, 6h and 40h, ultrafiltration, dilution, injection into HPLC for tracking analysis, using Daise Crown Ether column, Crownpak CR (+), D-Phe, tr=7.5min, L- Phe, tr = 11 min. The analysis time was extended to 60 min. No other detectable products were found. Separation with ion exchange resin to obtain pure D-phenylalanine (D-Phe).

[0024] Referring to Fig. 2, it i...

Embodiment 3D

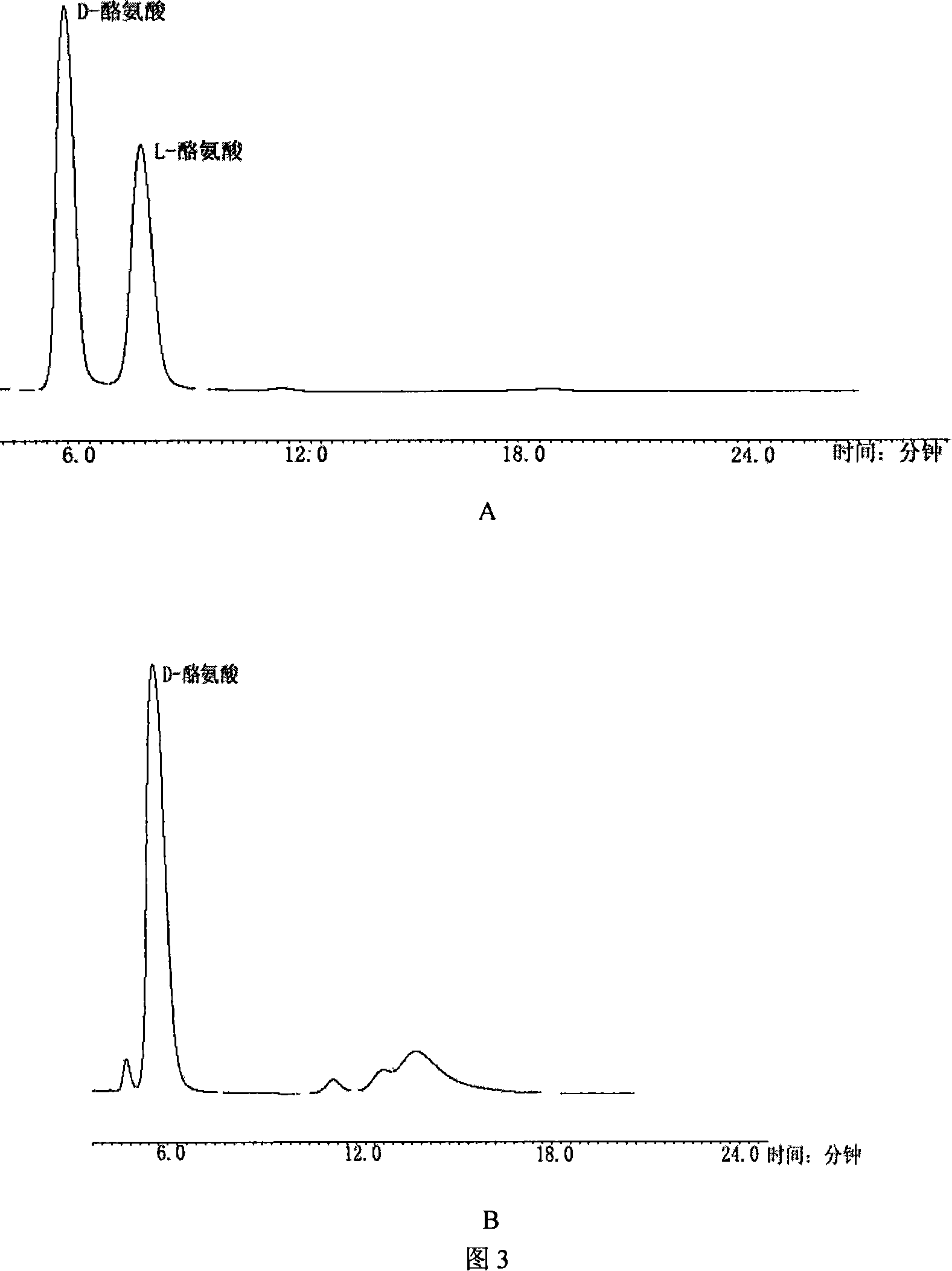

[0026] The preparation of embodiment 3D-tyrosine

[0027] In a 500mL shake flask, culture yeast (Rhodotorula graminis) (ATCC 20804), grow for 24 hours, centrifuge, pour out the clear liquid, freeze, ultrasonically break the wall, make a homogenate, put it back into the shake flask, Add racemate D, 50 mg of L-tyrosine; adjust the pH to 7.3, ventilate the air, put it back in the temperature-controlled shaker, shake it in a circular manner, take out one milliliter of samples for analysis in stages, and track the reaction progress. After 4 hours of reaction , 6h and 40h, ultrafiltration, dilution, injected into HPLC for follow-up analysis, using a large road crown ether chromatographic column, Crownpak CR (+), D-Tyr, tr=6min, L-Tyr, tr=9min. The analysis time is extended to 60 minutes. Separation with ion exchange resin to obtain pure D-tyrosine (D-Tyr).

[0028] Referring to Fig. 3, it is the change process of the amount of each substance in the biotransformation process of tyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com