Warp-weft two-way cross-layer connecting hollow fabric

A cross-layer and fabric technology, which is applied in the field of warp and weft two-way cross-layer connection hollow fabrics, can solve the problems of easy core structure and collapse, and achieve the effects of good energy absorption function, increased headroom height, and favorable bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

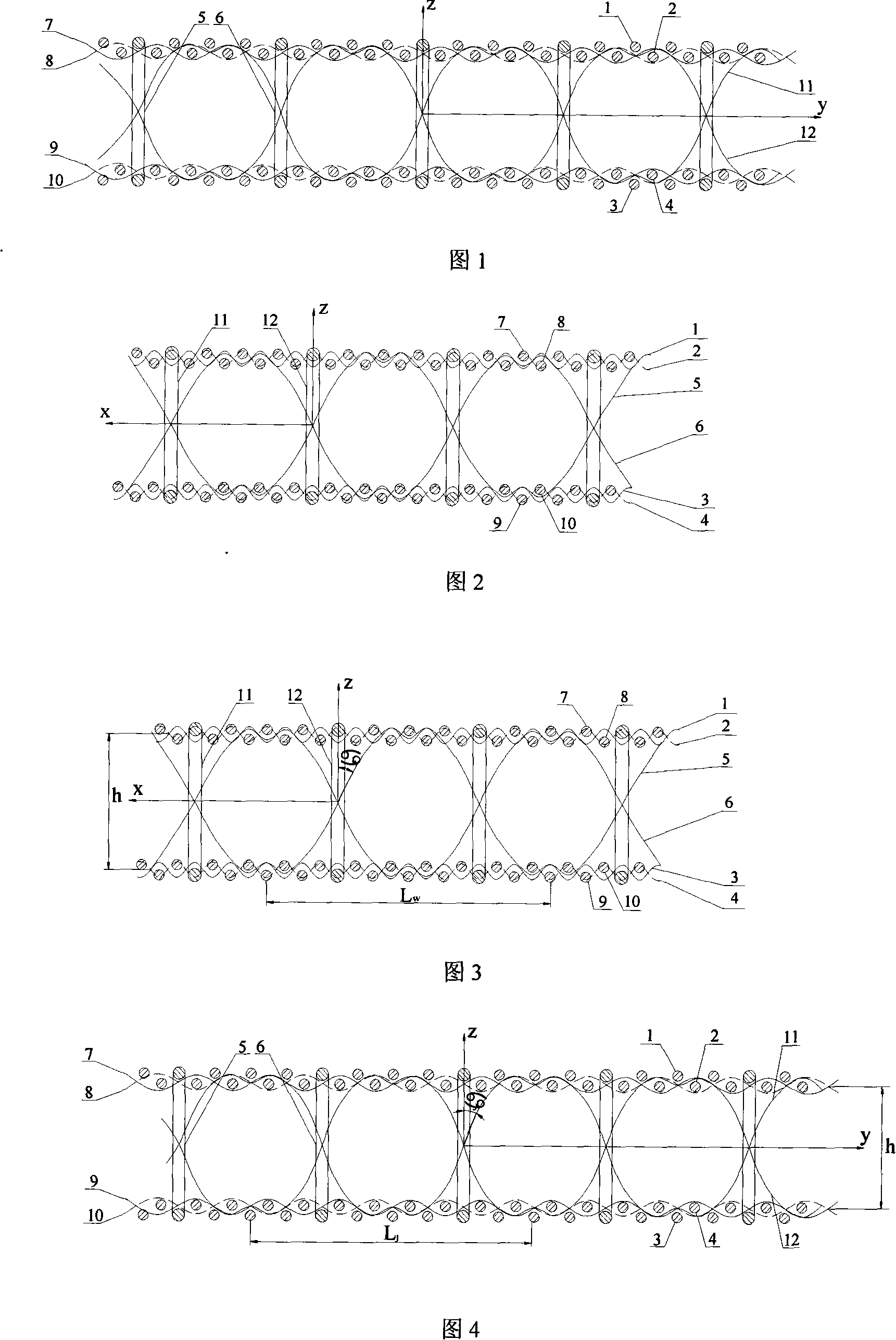

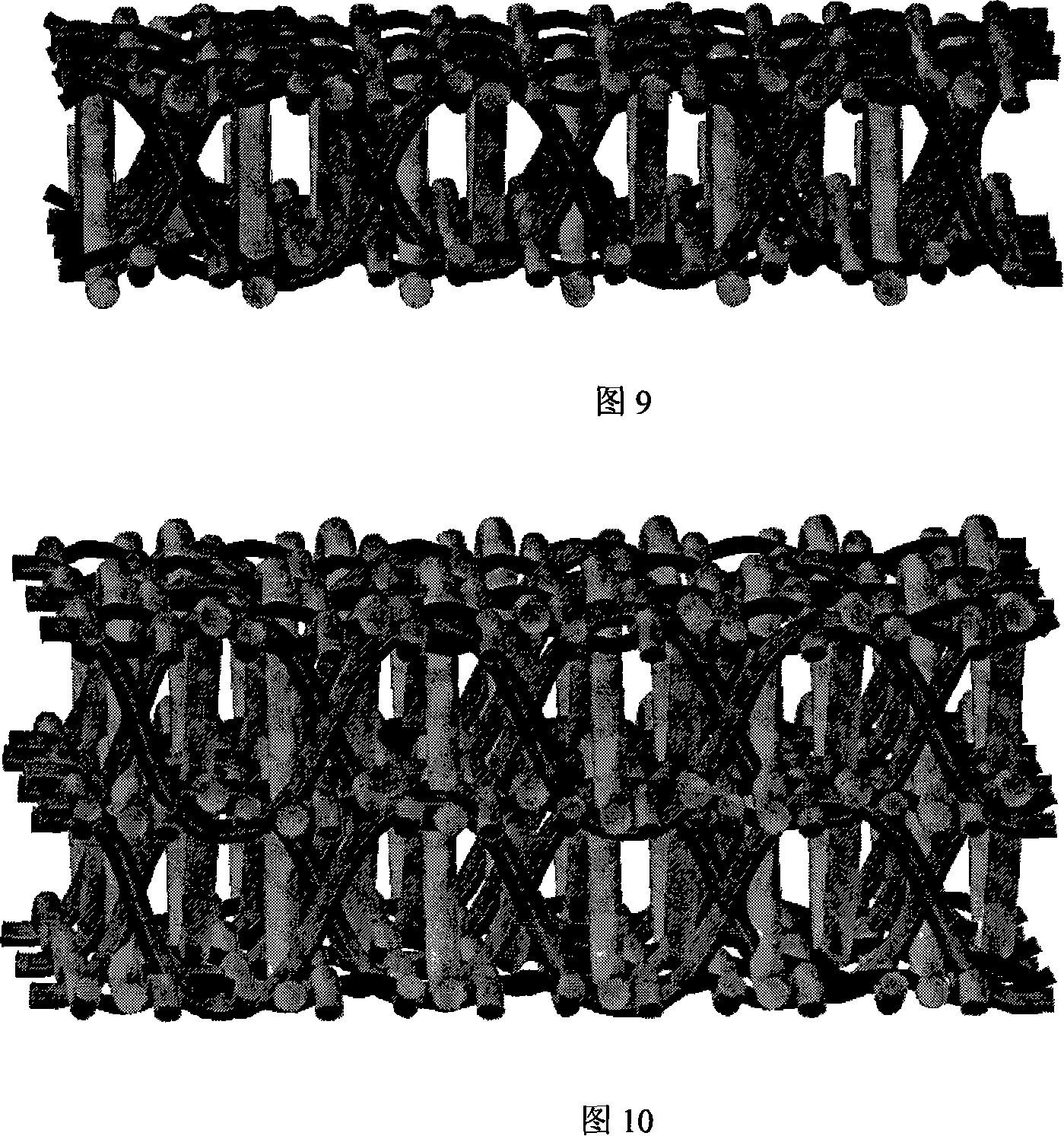

[0036] 1 to 4, 7 to 9, Example 1 consists of two systems of warp yarns (ground warps 7, 8, 9, 10 and connecting warps 11, 12) and two systems of weft yarns (ground weft 1, 2, 3, 4 and connecting wefts 5, 6) are interwoven or connected between layers. Ground warp (7, 8, 9, 10) and connecting warp (11, 12) respectively form two warp yarn systems; ground weft (1, 2, 3, 4) and connecting weft (5, 6) form two weft yarns respectively system. At the same time, it can also be considered that the two systems of connecting yarns (connecting warps 11, 12 and connecting wefts 5, 6) and two systems of ground weave yarns (ground warp yarns 7, 8, 9, 10 and ground yarns) that are perpendicular to each other Weft yarns 1, 2, 3, 4) are connected or interwoven across layers to connect the fabrics of the upper and lower layers into a whole.

[0037]Among them, the weft yarns (1, 2) of the upper layer and the warp yarns (7, 8) of the upper layer are interwoven to form the upper layer of the holl...

Embodiment 2

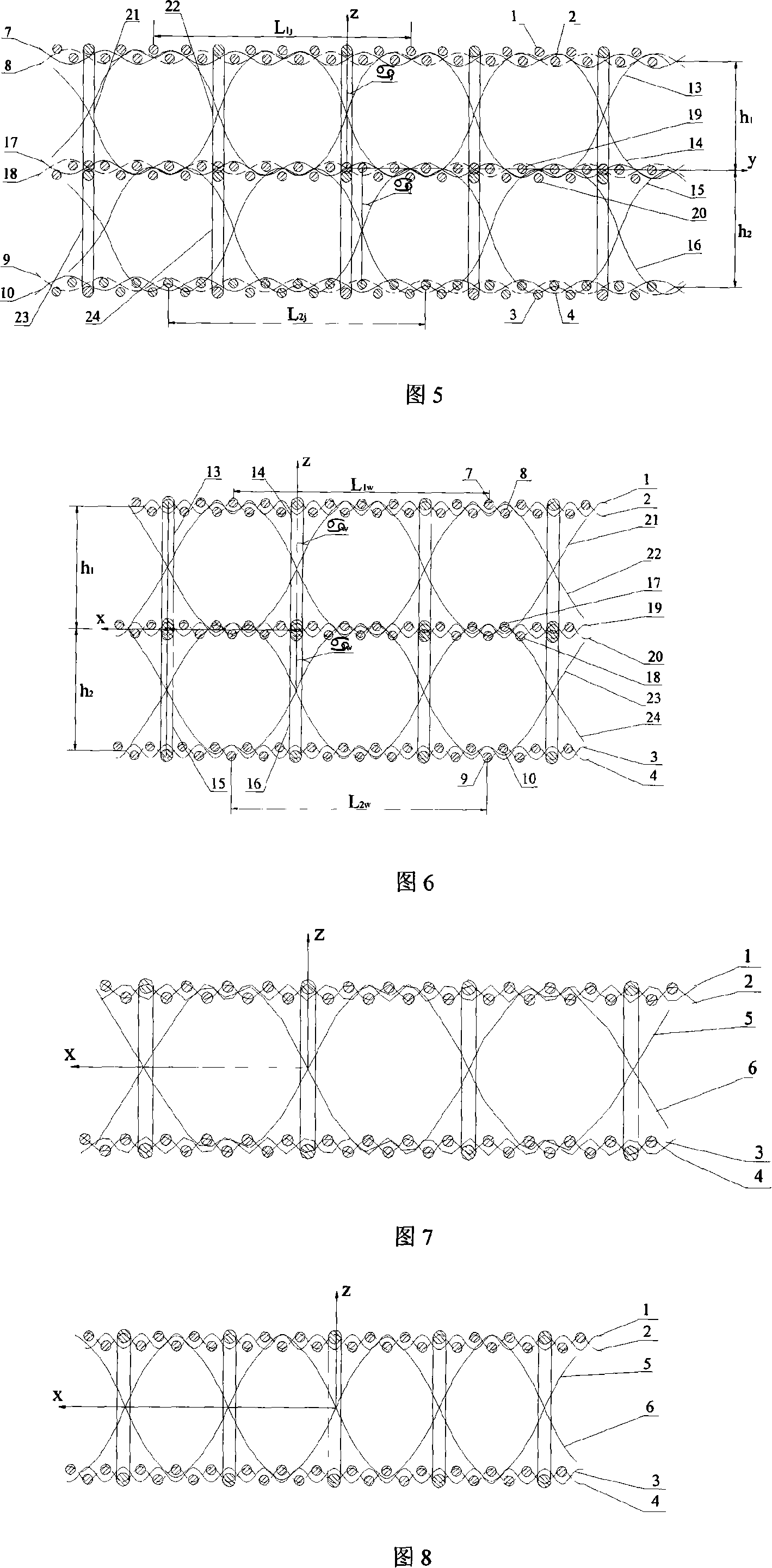

[0049] Referring to Fig. 5, Fig. 6 and Fig. 10, this embodiment includes a three-layer structure of an upper layer, a middle layer and a lower layer. The upper ground warp yarns (7, 8) interweave with the upper ground weft yarns (1, 2) to form the upper layer of the fabric, the middle ground warp yarns (17, 18) and the middle ground weft yarns (19, 20) interweave to form the middle plane of the fabric, and the lower ground The warp yarns (9, 10) interweave with the underlying weft yarns (3, 4) to form the lower layer of the fabric. The upper connecting warp yarns (13, 14) also interweave with the middle ground weft yarns (19, 20) across layers while interweaving with the upper ground weft yarns (1, 2), and the lower connecting warp yarns (15, 16) interweave with the middle ground weft yarns ( 19, 20) interweave while crossing layers and weft yarns (3, 4) of the lower layer. The upper connection weft yarn (21,22) also interweaves with the middle layer ground warp yarn (17,18) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com