Double helix angle beveled wheel engage assistant

A helical gear and double helix technology, applied in belts/chains/gears, components with teeth, hoisting devices, etc., can solve the problems of poor manufacturability, difficult clearance adjustment, complex structure, etc., and achieve good manufacturability, coincidence The effect of large coefficient and high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

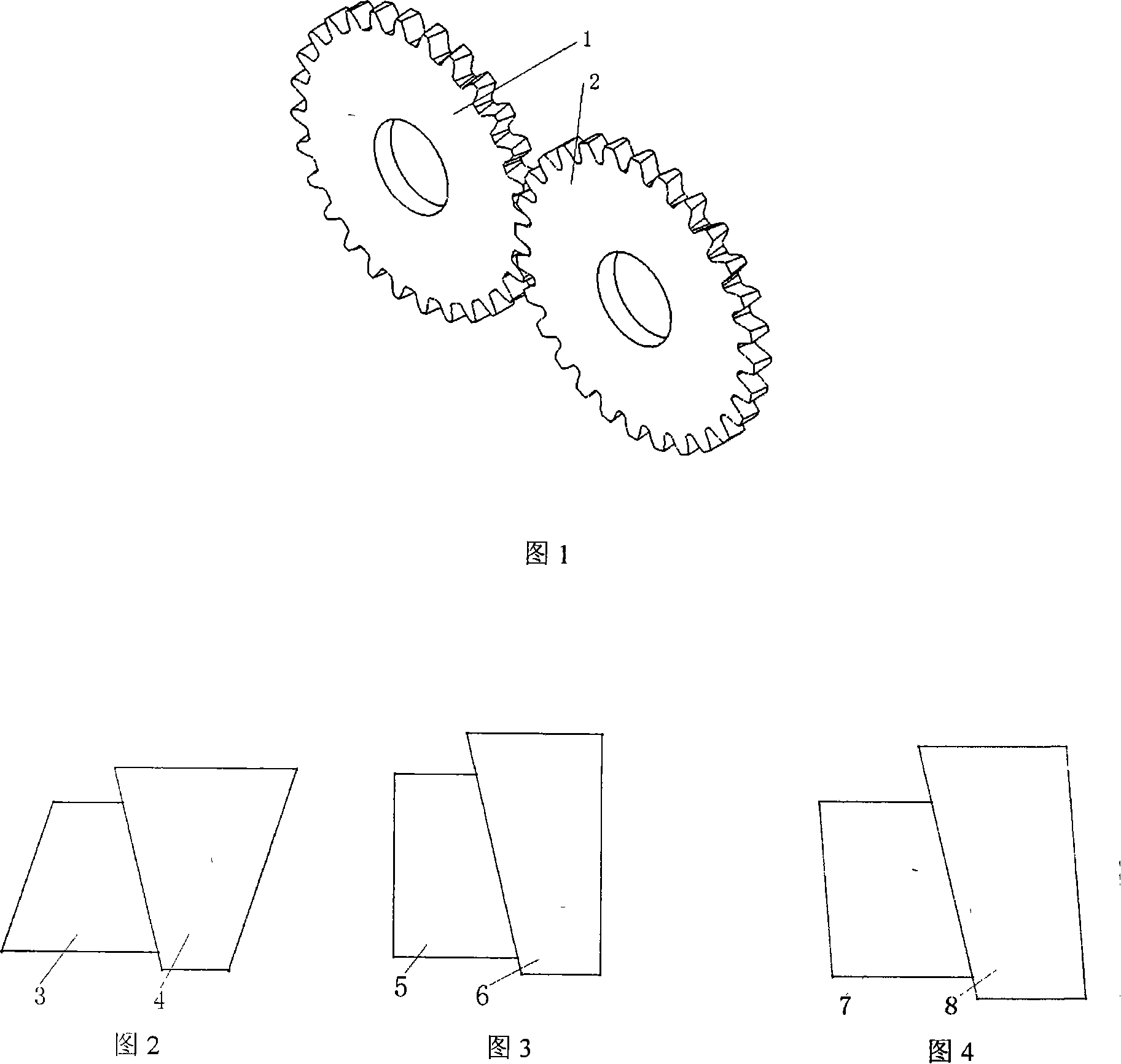

[0019] As shown in Figure 1, gear 1 and gear 2 are double helix angle helical gears with different helix angles. The right-handed helical tooth surface of gear 1 meshes with the left-handed helical tooth surface of gear 2; The right-handed helical tooth surfaces of gear 2 mesh. Due to the different helix angles, each tooth is tapered along the axial direction. Therefore, adjusting the relative position of gear 1 and gear 2 in the axial direction can adjust the meshing backlash of gear 1 and gear 2 to achieve precision. transmission.

[0020] Figure 2 shows the meshing of double helix angle helical gear teeth with opposite helix angles on the tooth surface, the double helix angle helical gear teeth 3 and 4 meshing with each other, the helix angles of teeth 3 and 4 Teeth of the same, opposite direction of rotation mesh. In Fig. 3, the helix angle of one tooth surface is zero, and the teeth 5 and 6 of the double helix angle helical gear with a non-zero helix angle of the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com