Disposable corn composite fertilizer and producing technique thereof

A compound fertilizer, one-time technology, applied in the direction of urea compound fertilizer, nitrogen fertilizer, potash fertilizer, etc., can solve the problems of reducing the fertilizer efficiency of one-time fertilization, failing to achieve one-time fertilization, etc., so as to improve the utilization rate of nitrogen fertilizer and reduce the loss of nitrogen. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 (the weight ratio of liquid ammonia and urea is 1:6.0; 231 kilograms of 45% phosphoric acid; 0.6 kilograms of amidine thiourea, 1.4 kilograms of thiourea)

[0034] The formula of the disposable corn compound fertilizer of the present invention is as follows:

[0035] Table 1

[0036] Liquid ammonia

(kg)

(kg)

(kg)

(kg)

amidinothiourea

(kg)

(kg)

Compound fertilizer 1

97.8

408.1

231.0

202.49

0.6

1.4

[0037] Its preparation steps are as follows:

[0038] The concentration is 45% (in P 2 O 5 Gauge) of dilute phosphoric acid was pressurized to 1MPa by phosphoric acid pump, and entered into the tubular reactor at 8.0t / h after metering control by flowmeter and regulating valve. Sulfuric acid with a concentration of 98% was pressurized to 1MPa by a sulfuric acid pump, and then entered into the tubular...

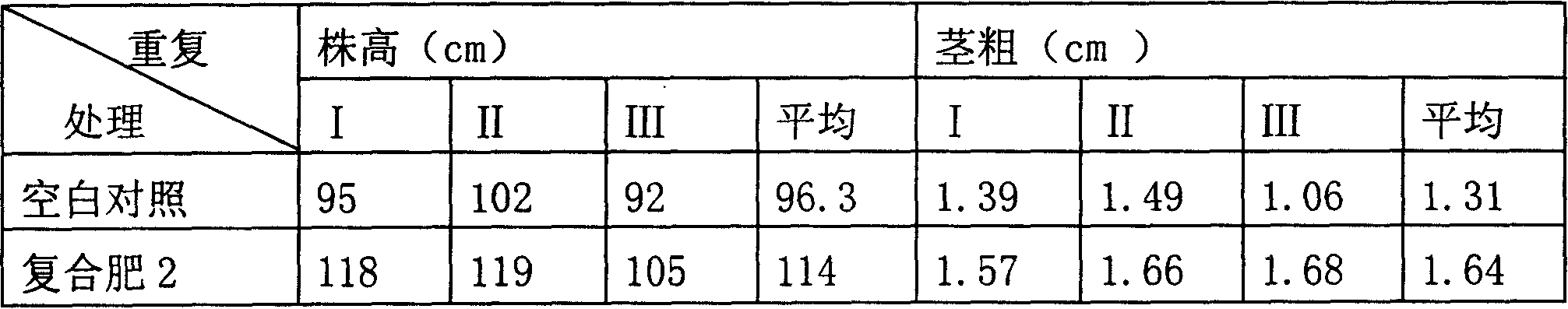

example 2

[0048] Example 2: (the weight ratio of liquid ammonia and urea is 1:6.2; 208 kg of 50% phosphoric acid; 1.0 kg of amidinothiourea, 1.0 kg of thiourea)

[0049] The formula of the disposable corn compound fertilizer of the present invention is as follows:

[0050] table 3

[0051] Liquid ammonia

(kg)

(kg)

(kg)

(kg)

amidinothiourea

(kg)

(kg)

Compound fertilizer 2

69.1

428.7

208

202.49

1.0

1.0

[0052] Its preparation steps are as follows:

[0053] The concentration is 50% (in P 2 O 5 Gauge) of dilute phosphoric acid was pressurized to 1MPa by phosphoric acid pump, and entered into the tubular reactor at 8.0t / h after metering control by flowmeter and regulating valve. Sulfuric acid with a concentration of 98% was pressurized to 1MPa by a sulfuric acid pump, and then entered into the tubular reactor at a rate of 6...

Embodiment 3

[0063] Embodiment 3 (the weight ratio of liquid ammonia and urea is 1:5.0; 208 kilograms of 50% phosphoric acid; 0.8 kilograms of amidine thiourea, 1.2 kilograms of thiourea)

[0064] The formula of the disposable corn compound fertilizer of the present invention is as follows:

[0065] table 5

[0066] Liquid ammonia

[0067] Its preparation steps are as follows:

[0068] The concentration is 50% (in P 2 O 5 Gauge) of dilute phosphoric acid was pressurized to 1MPa by phosphoric acid pump, and entered into the tubular reactor at 8.0t / h after metering control by flowmeter and regulating valve. Sulfuric acid with a concentration of 98% was pressurized to 1MPa by a sulfuric acid pump, and then entered into the tubular reactor at a rate of 6.0t / h after being metered and controlled by a flow meter and a regulating valve. Liquid ammonia (or gaseous ammonia, with a concentration of 99.5%) was metered and controlled by a flow meter and a regulating valve and entered th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com