Method for preparing ethylene glycol by catalysis hydration

A technology for catalyzing hydration and ethylene glycol, applied in hydrolysis preparation, organic chemistry, etc., can solve the problems of toxicity, affecting the quality of ethylene glycol products, and it is difficult to ensure high-quality polyester grade EG and EO, etc., to achieve low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

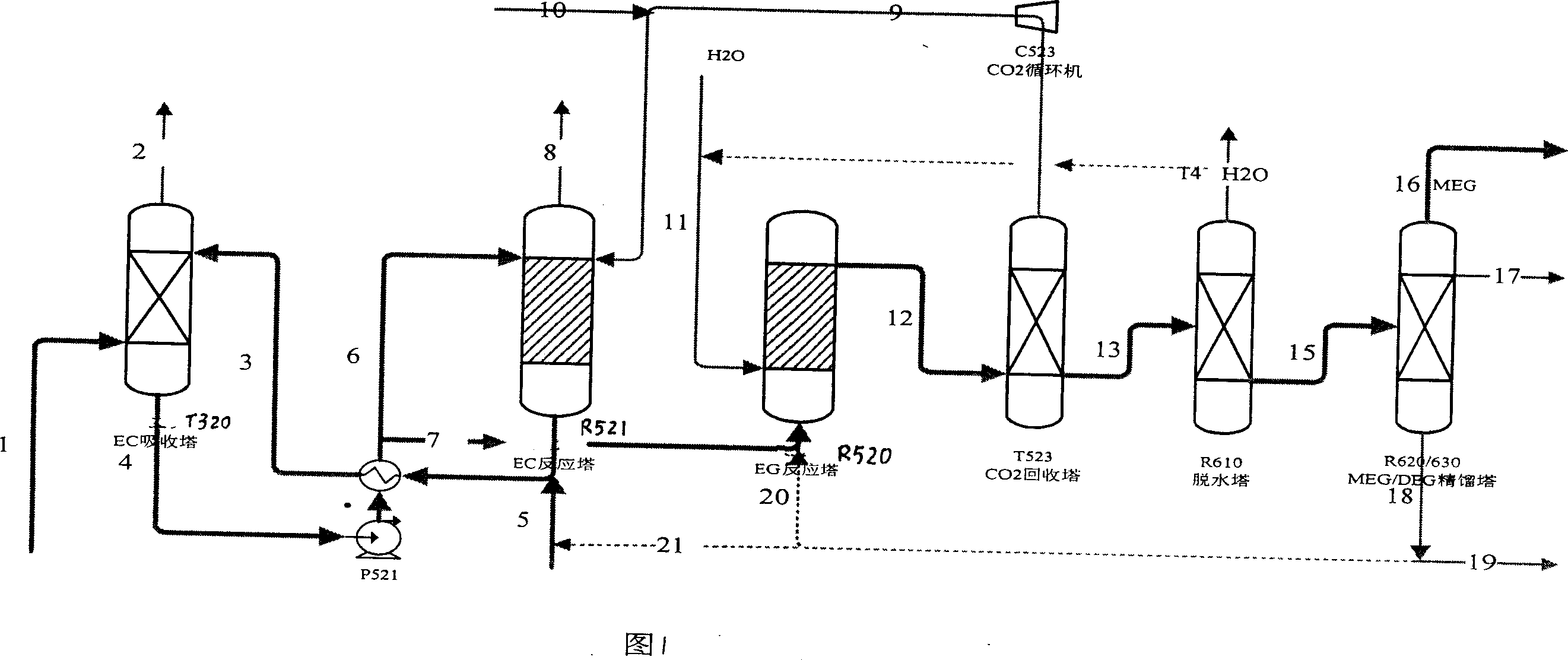

Image

Examples

Embodiment

[0042] (1) Absorption of ethylene oxide

[0043] The 60°C (50-90°C) gas obtained by desorption, containing 78mol% (generally obtain this content) of ethylene oxide, is introduced at a rate of 0.54kmol / h through the bottom of the countercurrent packed absorption tower T320 containing 40 layers , containing each 2~3% moles of potassium bromide and potassium carbonate (mixed with 50:50 by weight) bimetallic salt catalyst (catalyst and ratio need not be specifically limited) and ethylene carbonate of 20% moles of water (the content of water is not particularly limited) The mixed solution of ester and ethylene glycol (mixed by weight at 50:50, no special limitation) is used as the absorption solution at 40°C (room temperature is also acceptable) at 3.0kmol / h (the flow rate is not particularly limited, it can be proportional to the gas, and The volume of the tower) flows down from the top of the tower for countercurrent contact, and the absorption operating pressure is 0.13MPa (0.1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com