Method for extracting and culturing strain capable of making tea fragrant

A cultivation method and technology for aged tea, which are applied in the directions of pre-extraction tea treatment, fungi, etc., can solve the problems of slow fermentation speed, insufficient quality, deterioration of tea leaves, etc., and achieve stable composition ratio, improve quality and flavor, and be easy to make. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

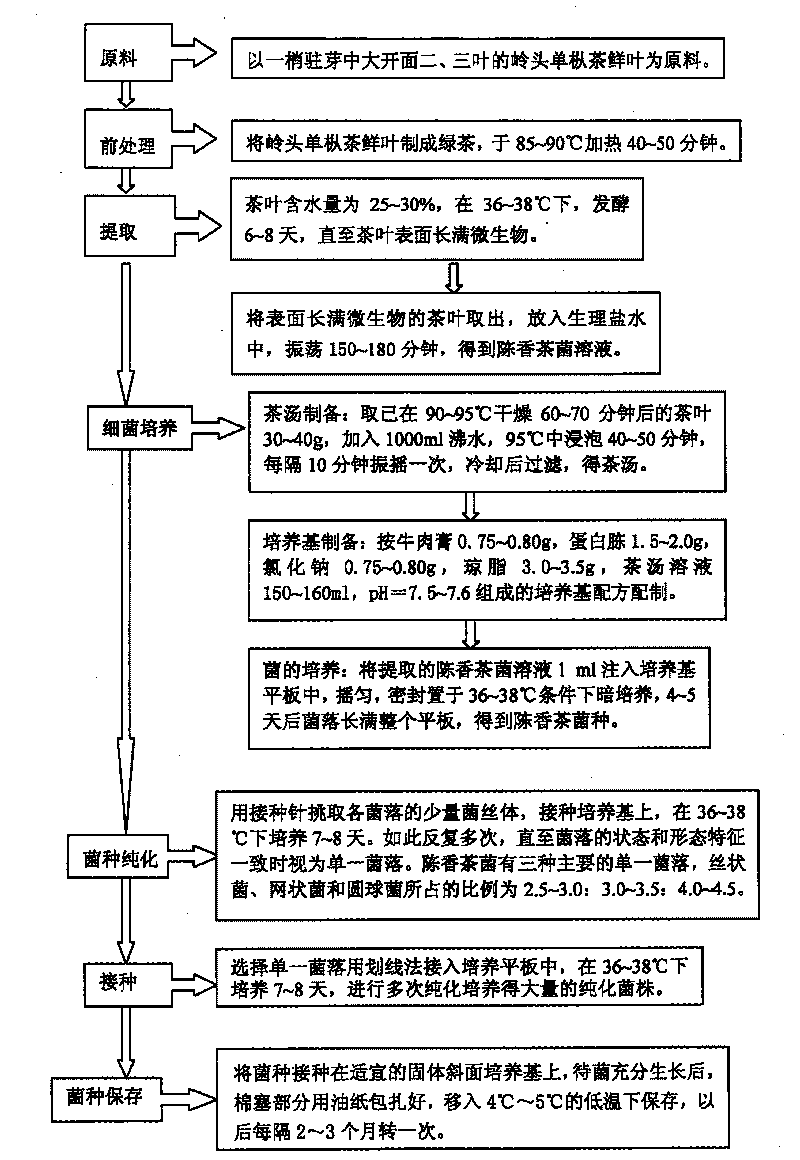

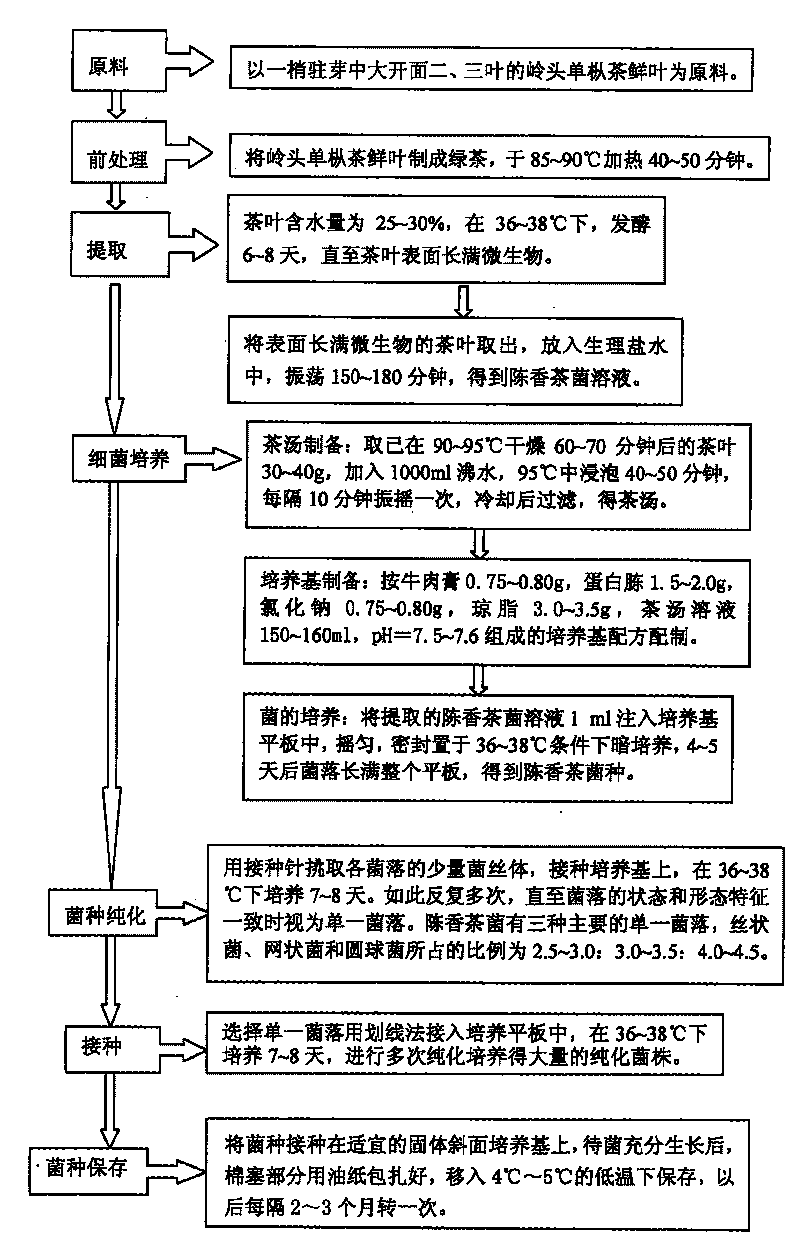

[0024] The preparation procedure flowchart of the present invention is attached figure 1 As shown, it specifically includes the following steps:

[0025] (1) Selection of raw materials: The fresh leaves of Lingtou Dancong tea with large openings and two or three leaves in a shoot bud are used as raw materials.

[0026] (2) Raw material treatment: prepare green tea from the fresh leaves of Lingtou Dancong tea according to the green tea manufacturing process, heat at 85-90° C. for 40-50 minutes, and kill the microorganisms remaining on the tea leaves.

[0027] (3) Extraction of aged tea fungus: put the processed raw materials in step (2) into a sealed container, add sterile water to make the water content of the tea leaves 25-30%, and ferment for 6 hours at 36-38°C ~8 days, until the surface of the tea leaves is covered with microorganisms. Take out the tea leaves covered with microorganisms on the surface, put them into physiological saline, shake for 150-180 minutes, let the...

Embodiment 1

[0037] The concrete steps of embodiment 1 are as follows:

[0038] (11) Selection of raw materials: The fresh leaves of Lingtou Dancong tea with large openings and two or three leaves in a shoot bud are used as raw materials.

[0039] (12) Raw material treatment: prepare green tea from the fresh leaves of Lingtou Dancong tea according to the green tea manufacturing process, heat at 85° C. for 40 minutes, and kill the microorganisms remaining on the tea leaves.

[0040] (13) Extraction of aged tea fungus: put the processed raw materials in step (12) into a sealed container, add sterile water to make the water content of the tea leaves 25%, and ferment for 6 days at 37°C until the tea leaves The surface is overgrown with microorganisms.

[0041] The tea leaves covered with microorganisms on the surface are taken out, put into physiological saline, and shaken for 150 minutes, so that the microorganisms on the tea leaves are transferred into the solution to obtain the aged tea fu...

Embodiment 2

[0050] The concrete steps of embodiment 2 are as follows:

[0051] (21) Selection of raw materials: The fresh leaves of Lingtou Dancong tea with large openings and two or three leaves in a shoot bud are used as raw materials.

[0052] (22) Raw material treatment: prepare green tea from the fresh leaves of Lingtou Dancong tea according to the green tea manufacturing process, heat at 90° C. for 50 minutes, and kill the microorganisms remaining on the tea leaves.

[0053] (23) Extraction of aged tea fungus: put the processed raw materials in step (22) into a sealed container, add sterile water to make the water content of the tea leaves 30%, and ferment them for 8 days at 38°C until the tea leaves The surface is overgrown with microorganisms.

[0054] The tea leaves covered with microorganisms on the surface are taken out, put into physiological saline, and shaken for 180 minutes, so that the microorganisms on the tea leaves are transferred into the solution to obtain an aged te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com