Light solidifying coloring composition and color filter using the same

A coloring composition and photocurable technology, which is applied in the direction of instruments, optics, and optomechanical equipment, can solve the problems of residual film rate, pixel intensity, pattern shedding or defect, resolution support body adhesion decline, etc., to achieve optical Improved curing efficiency and high cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0259] Here, an example in which a photocurable coloring composition α-1 containing a colorant (pigment) is prepared, and the curable composition α-1 is used to produce a color filter for use in a liquid crystal display element will be described.

[0260] [1. Preparation of photocurable coloring composition α-1]

[0261] 1-1. Preparation of pigment dispersion (Q1): black

[0262] As the pigment, 27 parts by mass of carbon black MA-20 [manufactured by Mitsubishi Chemical Corporation, specific black pigment (A)], benzyl methacrylate / methacrylic acid copolymer (copolymerization ratio 70 / 30 molar ratio, weight average molecular weight A mixed liquid consisting of 30000) 8 parts by mass and 65 parts by mass of propylene glycol monomethyl ether acetate was mixed and dispersed by a bead mill for 20 hours to prepare a pigment dispersion (Q1).

[0263] Regarding the obtained pigment dispersion liquid (Q1), the average particle diameter of the pigment was measured according to the dynamic l...

Embodiment 2~12

[0313] At least 1 of the specific initiator (compound 1) in the composition α-1 used to prepare the photocurable coloring composition α-1 in Example 1 and the black pigment used in the pigment dispersion liquid (Q1) All of them were replaced with those shown in Table 1 below, except that the photocurable coloring compositions α-2 to α-12 were prepared in the same manner as in Example 1. Using these, in the same manner as in Example 1, a color filter having a colored pattern was obtained. In addition, the same evaluation as in Example 1 was performed. The results are shown in Table 1.

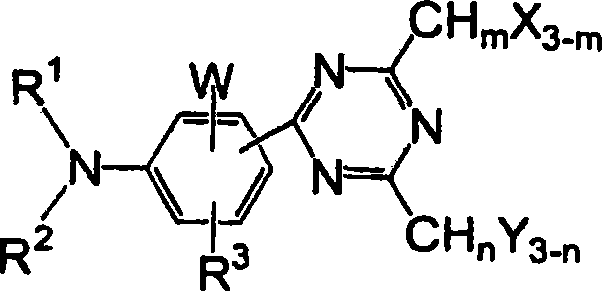

[0314] In addition, the structures of the specific initiators (Compound 2 to Compound 4) used here are shown below.

[0315] Compound 2

[0316]

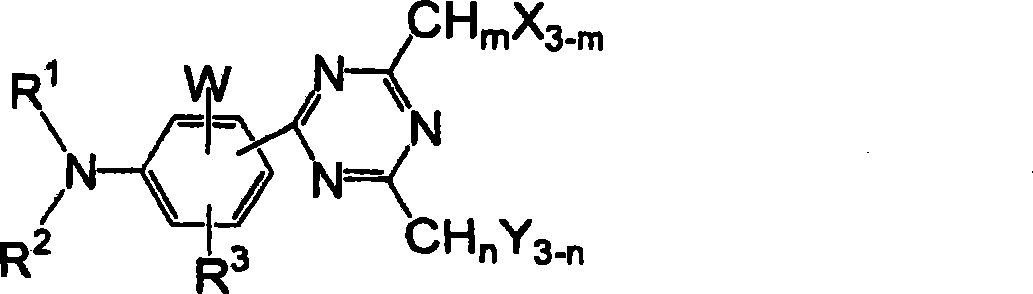

[0317] Compound 3

[0318]

[0319] Compound 4

[0320]

[0321] The details of the black pigments (for the present invention, for comparison) described in Table 1 are as follows.

[0322] [Specific black pigment (A): non-coated type] Specific surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com