Easy-to-clean milling and boiling integrated soya-bean milk machine

An easy-to-clean soymilk machine technology, applied in the field of soymilk-making devices, can solve the problems of difficult cleaning of filter cups, unsatisfactory crushing of soybean materials, and short circuit of circuit boards, etc., to achieve good taste, less solid particles, and sufficient flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following examples are further explanations and illustrations of the present invention, and do not constitute any limitation to the present invention.

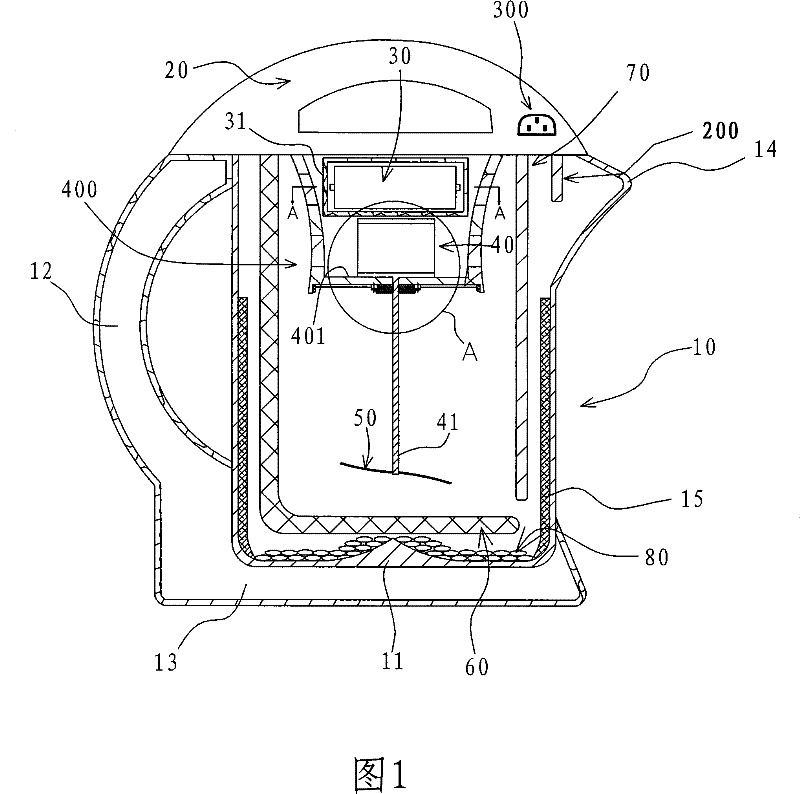

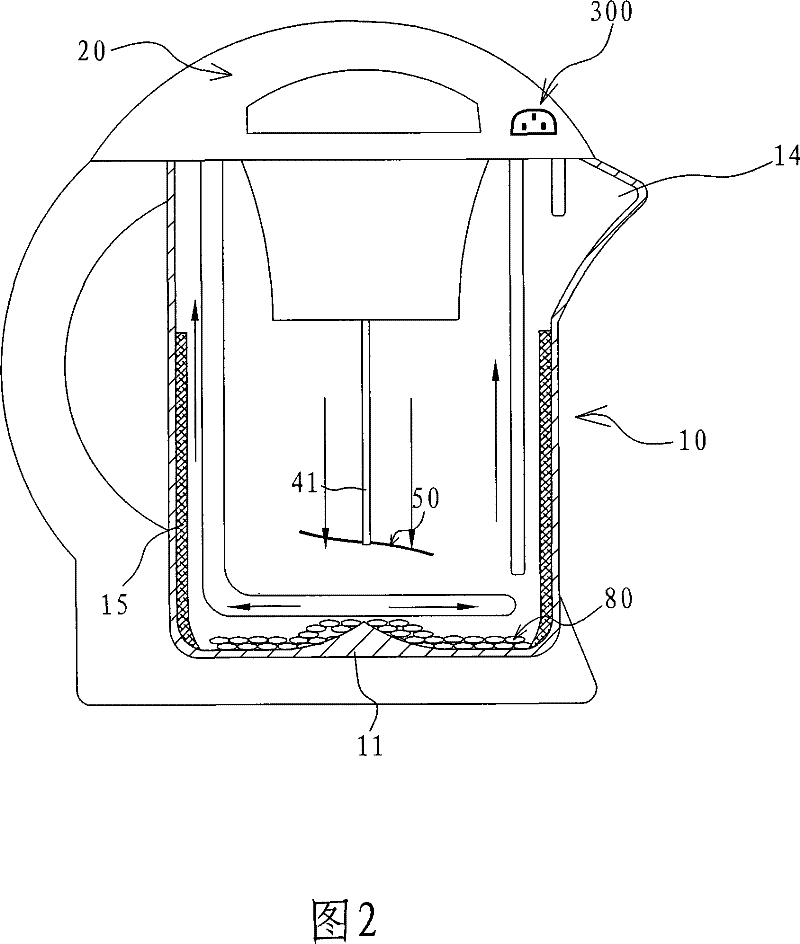

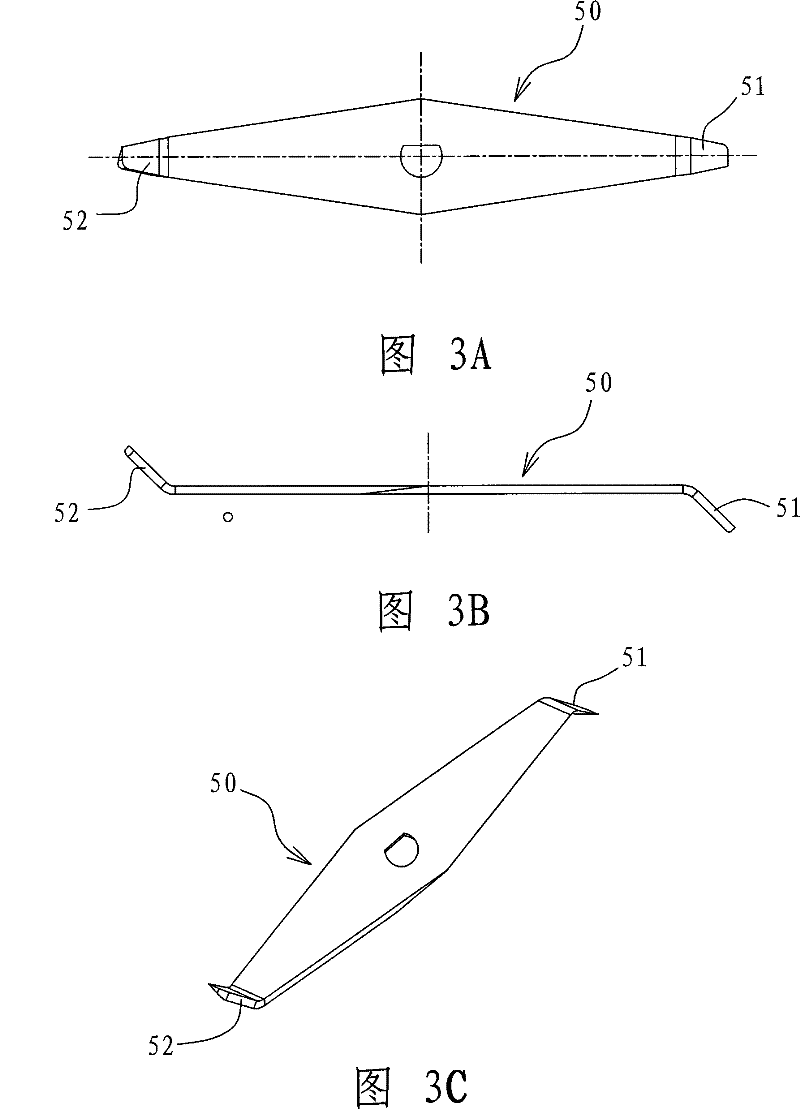

[0021] Referring to FIG. 1 , the easy-to-clean integrated grinding and cooking soybean milk machine of the present invention includes a body 10 , an upper cover 20 , a circuit board 30 , a motor 40 , a rotating blade 50 , an electric heating element 60 , an overflow prevention switch 200 and a temperature sensor 70 . The body 10 is a cylindrical body with an open upper part made of plastics or metal. It is provided with a protruding liquid outlet 14 on the side wall near the top. Base 13. A detachable upper cover 20 is arranged on the upper part of the body, and a micro switch is arranged between the upper cover and the handle 12 and snapped together. The upper cover 20 is a hollow body, in which devices such as power terminals 300 can be installed, and the power terminals are connected to the circuit board 30 thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com