Method of preparing functional ceramic material

A technology of functional ceramics and premixed liquid, applied in the field of preparing functional ceramic materials, can solve the problems of deformation and bending of ceramic body, slow down drying rate, large size, etc., to prevent deformation and cracking, shorten drying time, and ensure uniformity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

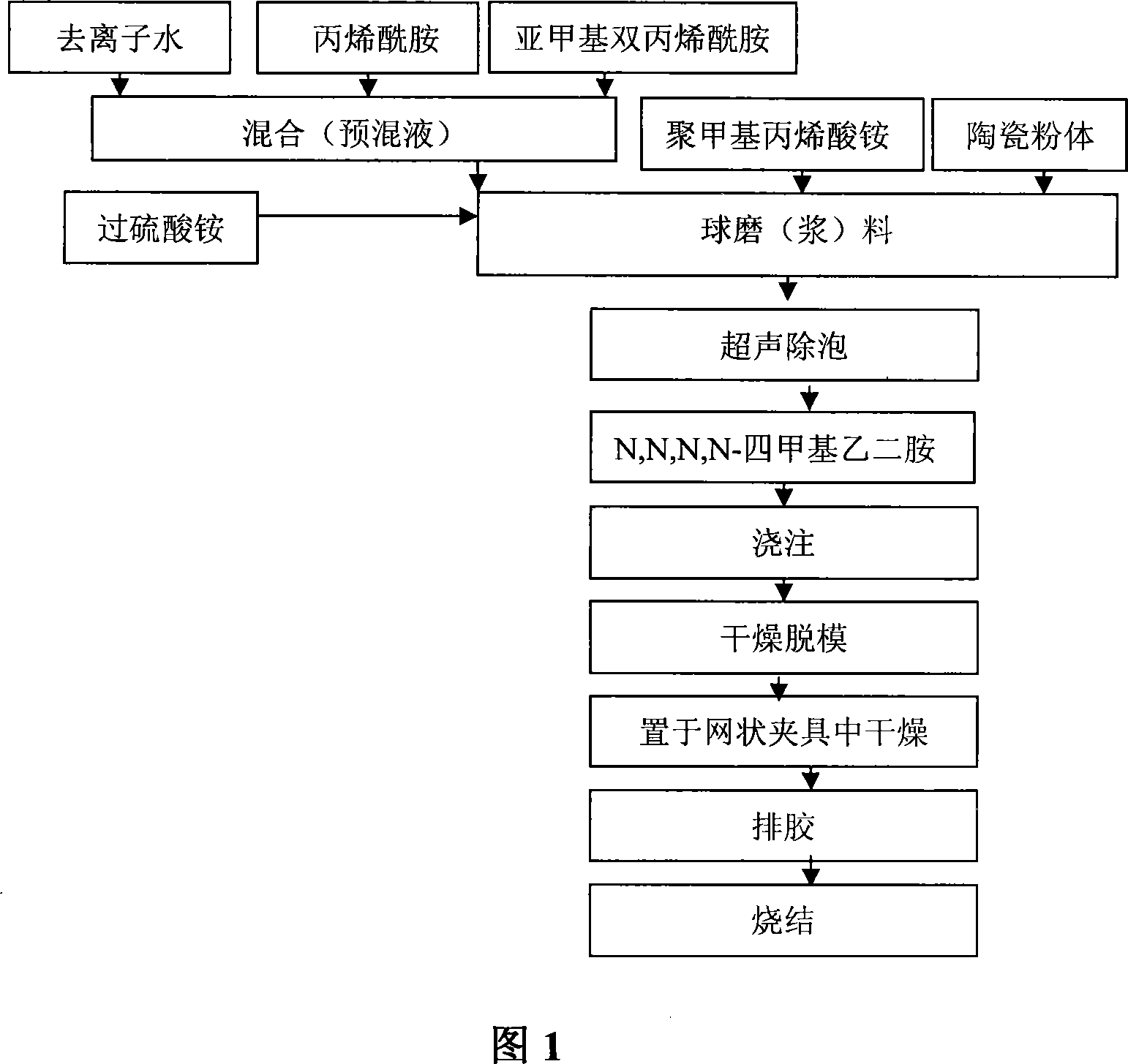

Method used

Image

Examples

example 1

[0021] Preparation of large size 0.15(PbZn 1 / 3 Nb 2 / 3 o 3 )+0.85[Pb(Zr 0.54 Ti 0.46 )O 3 ]Piezoelectric Ceramics.

[0022] The specific process is:

[0023] (1) by chemical formula, prepare PZN-PZT powder with solid phase synthesis method;

[0024] (2) 500g powder was mixed with 65.8ml premix, 25g dispersant and 1.75g initiator and ball milled for 2 hours to prepare a slurry with a solid phase content of 50vol% and a viscosity of 90mPa.s;

[0025] (3) Pour out the slurry, add catalyzer 0.8g, pour in the annular mold of Φ 21cm, the mold is the glass plate that the surface is stuck with metal ring, so that demoulding;

[0026] (4) The mold is placed in the air for 24 hours and demoulded, and then put into a mesh fixture, wherein the mesh fixture is a square steel wire mesh with two side lengths of 25cm, and the four sides are fixed with steel bars, and then the four sides of the steel bars are fixed. Drill four screw holes at the corner to clamp the two steel meshes to...

example 2

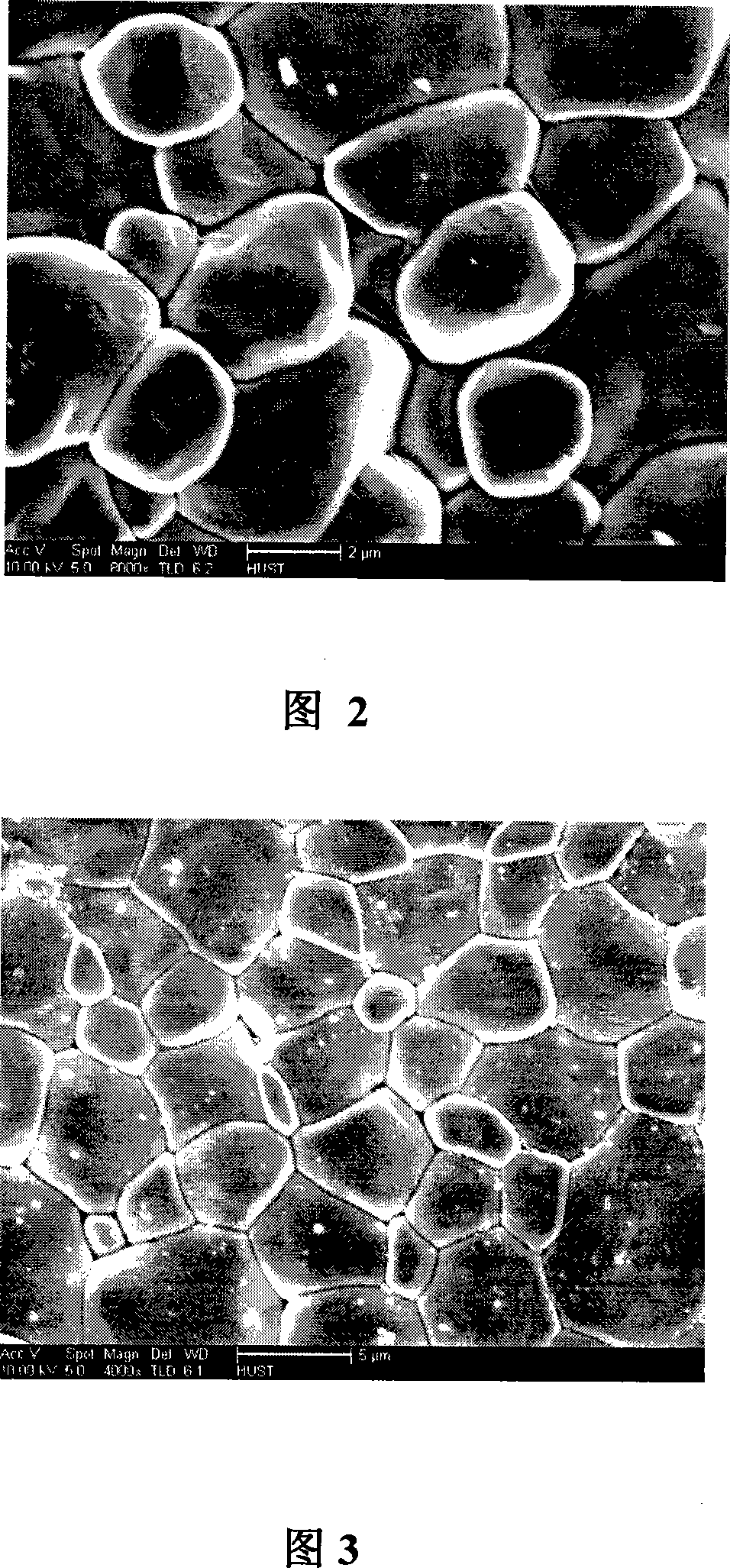

[0034] Preparation of large-sized Pb[(Mn 0.3 Nb 0.7 ) 1 / 2 (Mn 0.3 Sb 0.7 ) 1 / 2 ] 0.2 (Zr 95 Ti 5 ) 0.8 o 3 Pyroelectric ceramics. According to the chemical formula, the powder is prepared by the solid phase synthesis method, the sintering temperature is 1240°C, and the others are the same as in Example 1. The size of the ceramic after sintering is Φ15.8cm, and the density is 7.51g / cm 3 , using the same method to test its dielectric constant is 251, dielectric loss is 4%, pyroelectric coefficient is 7.5×10 -4 C / m 2 °C (30 °C), the dielectric constant uniformity is 4.8%, and its SEM image is shown in Figure 3.

example 3

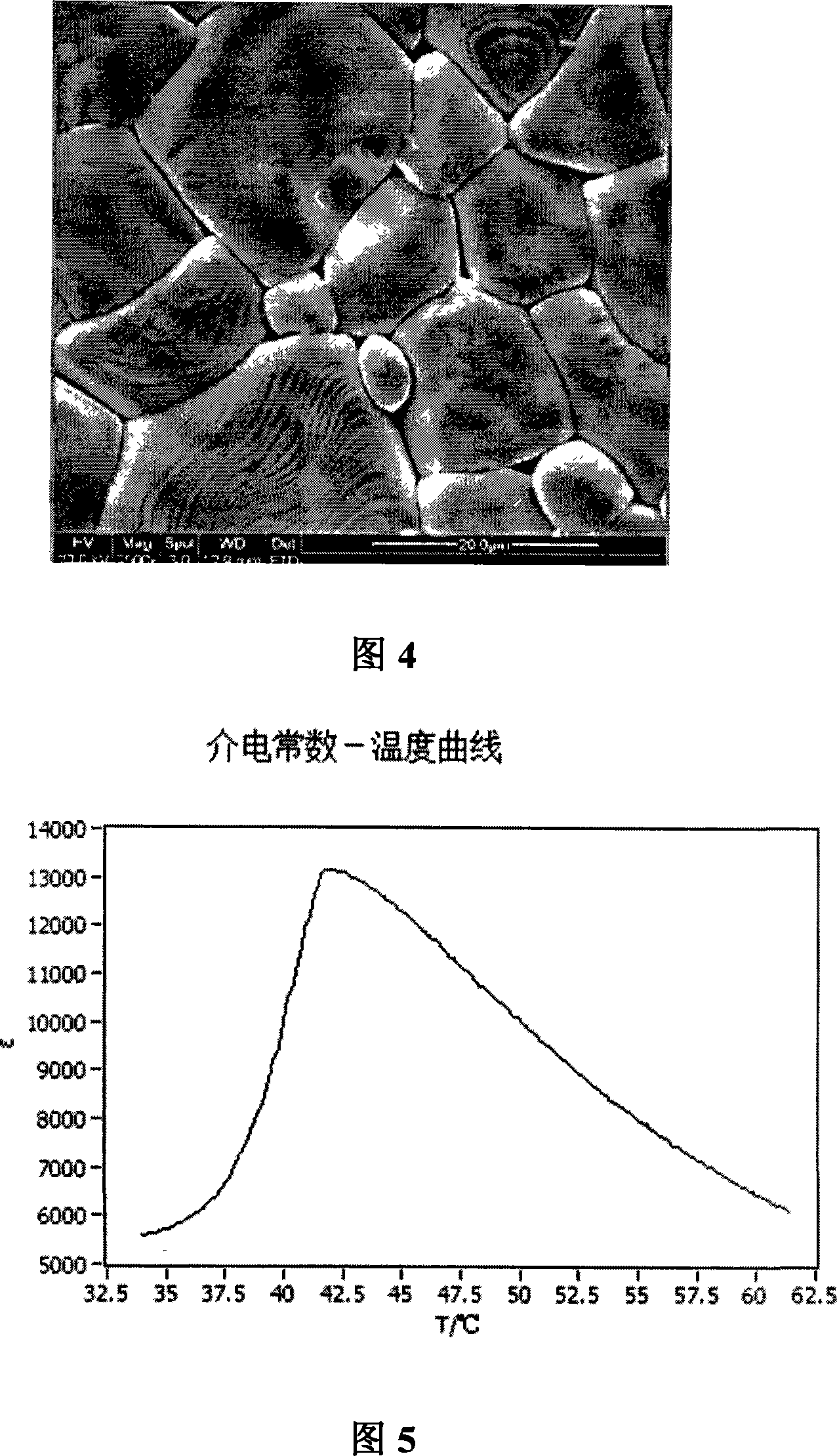

[0036] Preparation of large-sized Ba by water-based gel injection molding combined with mesh fixture drying method 0.7 Sr 0.3 TiO 3 Pyroelectric ceramics.

[0037] The specific process is:

[0038] (1) by chemical formula, prepare BST powder with solid-phase synthesis method;

[0039] (2) 300g powder was mixed with 50ml premix, 15g dispersant and 1.35g initiator and ball milled for 2 hours to prepare a slurry with a solid phase content of 48vol% and a viscosity of 110mPa·s;

[0040] (3) pour out the slurry, add catalyst 0.7g, inject in the mold, and pour in the mold of Φ 16cm;

[0041] (4) Place the mold in the air for 24 hours before demoulding, put in the mesh fixture, put the fixture in a constant temperature and humidity box, place it in a humidity of 95% and a temperature of 10°C for three days, then adjust it to a humidity of 80%, Place it in a temperature of 25°C for two days, then adjust it to a humidity of 65% and a temperature of 30°C for three days;

[0042](5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com