High-sensitivity resonance type optical fiber peg-top based on slow light group velocity

A high-sensitivity, fiber optic gyroscope technology, applied in the coupling of optical waveguides, Sagnac effect gyroscopes, optics, etc., can solve the problems of low sensitivity, unable to meet the attitude alignment of missiles and commercial aircraft, and achieve small size, The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

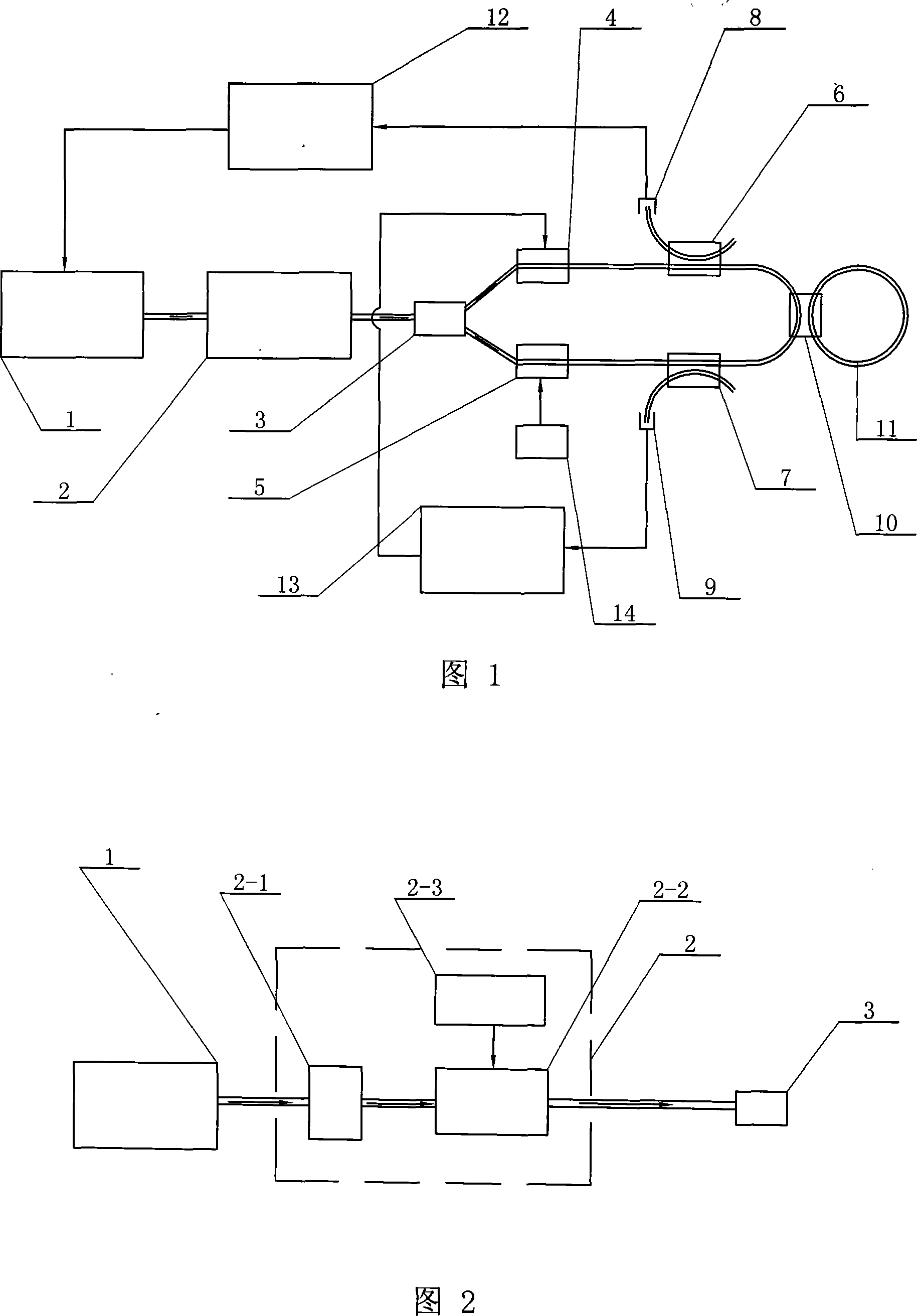

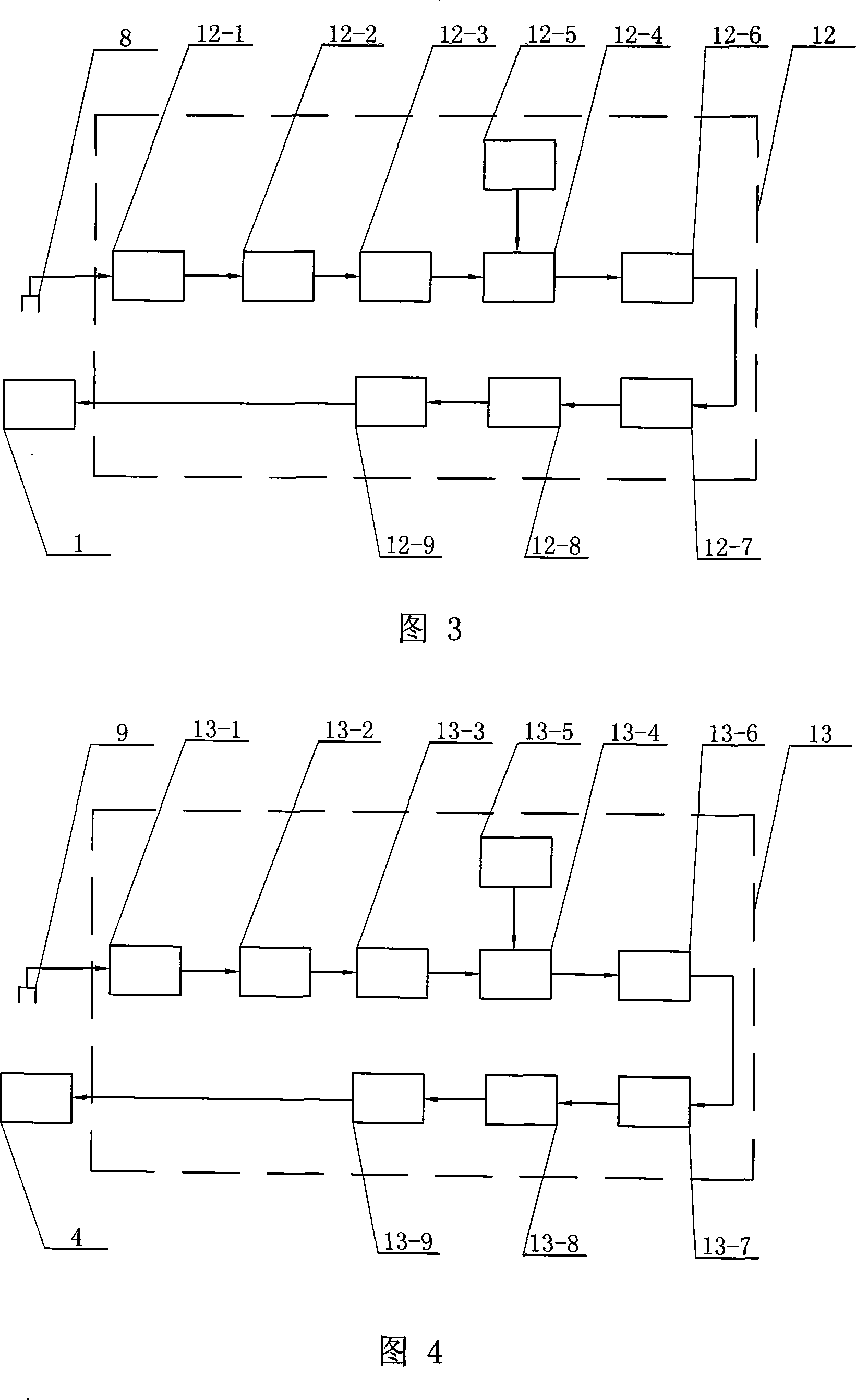

[0008] Specific Embodiment 1: This embodiment is described in conjunction with Fig. 1, Fig. 2, Fig. 3, and Fig. 4. This embodiment consists of a frequency conversion laser 1, a group velocity control system 2, an optical fiber beam splitter 3, and a first lithium niobate phase modulator 4. The second lithium niobate phase modulator 5, the first fiber coupler 6, the second fiber coupler 7, the first detector 8, the second detector 9, the third fiber coupler 10, the dispersion fiber ring resonator 11. The first signal processing and feedback system 12, the second signal processing and feedback system 13, and the modulation signal generating circuit 14;

[0009] The dispersion fiber ring resonator 11 is a hollow coil wound by a dispersion fiber; the laser output end of the frequency conversion laser 1 is connected to the optical input end of the group velocity control system 2 through an optical fiber, and the optical output end of the group velocity control system 2 is connected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com