Flame retardance poly- p-benzene dicarboxylic acid trimethylene glycol ester and method for producing the same

A technology of trimethylene phthalate and a production method, which are applied in the field of flame retardant polytrimethylene terephthalate and its production, can solve the problems of unsustainable flame retardant performance, poor appearance of textiles, low flame retardant performance, and the like, To achieve the effect of simple process, excellent performance and stable flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

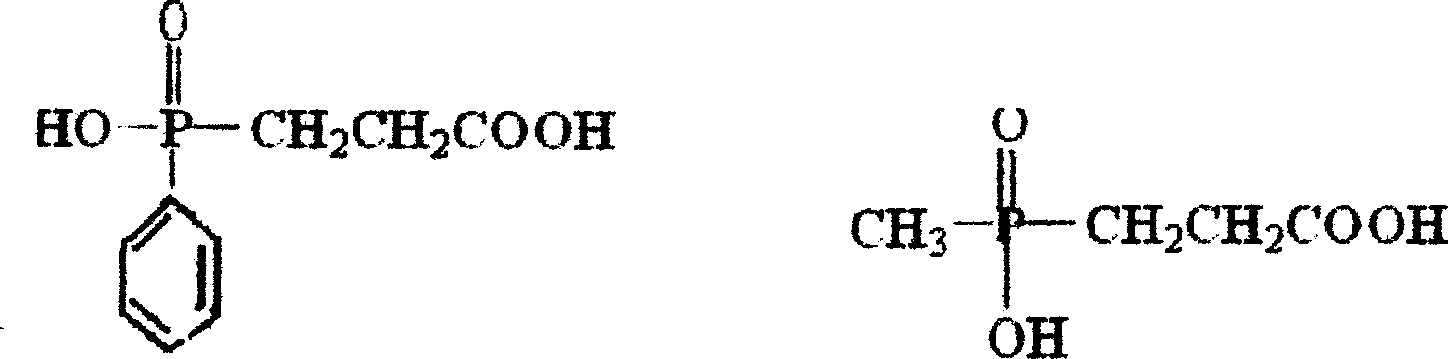

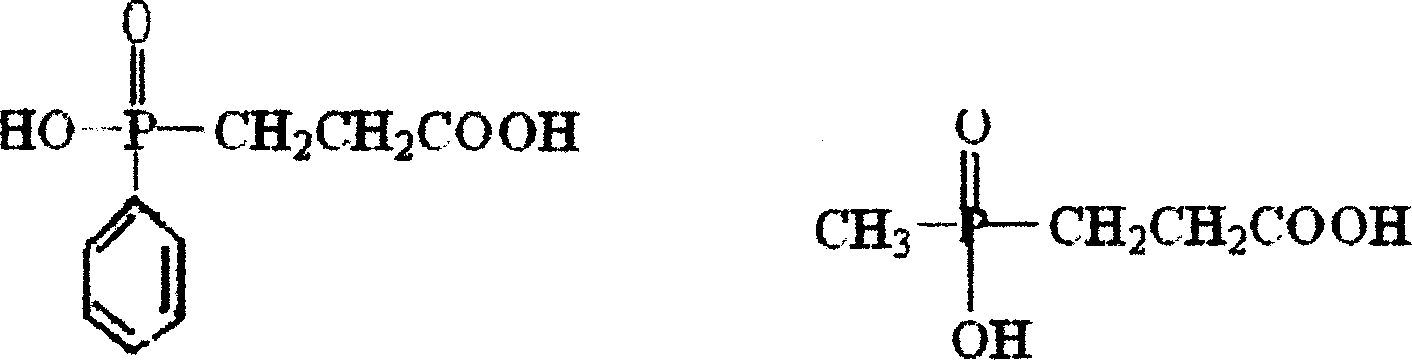

[0022] 1. Prepare propylene glycol solution of phosphoric acid ester: take 4.97 parts by weight of flame retardant shown in chemical formula (1), 8.49 parts of 1,3-propanediol, add them to the esterification kettle, and gradually heat up to 165°C under stirring , carry out the esterification reaction under normal pressure conditions, and when the water no longer distills off, the reaction ends, and a propylene glycol propionate-based phenylphosphate propylene glycol ester solution is obtained.

[0023] 2. Esterification and polycondensation: Take 166 parts of purified terephthalic acid and 89 parts of 1,3-propylene glycol to make a slurry, then transfer it to an esterification kettle, and carry out esterification reaction at a temperature of 225°C and normal pressure. End the esterification when no longer distilling off, move the esterification product into the polymerization device, add the propylene glycol propionate-based propylene glycol phenylphosphate solution prepared ab...

Embodiment 2

[0025] 1. Prepare propylene glycol solution of phosphoric acid ester Take 5.0 parts by weight of phosphorus-containing flame retardant shown in chemical formula (2), 10.66 parts of 1,3-propanediol, join in the esterification kettle, under stirring, gradually heat up to 165 ℃, carry out the esterification reaction under the condition of normal pressure, when the water no longer distills off, the reaction ends, and the propylene glycol solution of the phosphoric acid ester is obtained.

[0026] 2. Esterification and polycondensation Take 166 parts of purified terephthalic acid and 89 parts of 1,3-propanediol to make a slurry, then transfer it to an esterification kettle, and carry out esterification reaction at a temperature of 225°C and normal pressure. End esterification when distilling off again, move the esterification product into the polymerization device, add the propylene glycol solution of the phosphoric acid ester prepared above, then add the catalyst, stabilizer and an...

Embodiment 3

[0028] 1. Preparation of propylene glycol solution of phosphoric acid ester Take 22.77 parts by weight of phosphorus-containing flame retardant shown in chemical formula (3) and 29.83 parts of 1,3-propanediol, add them to the esterification kettle, and gradually heat up to 165 ° C under stirring , carry out the esterification reaction under normal pressure conditions, when the water no longer distills out, the reaction ends, and the propylene glycol solution of the phosphate ester is obtained.

[0029] 2. Esterification and polycondensation Take 166 parts of purified terephthalic acid and 89 parts of 1,3-propanediol to make a slurry, then transfer it to an esterification kettle, and carry out esterification reaction at a temperature of 225°C and normal pressure. End esterification when distilling off again, move the esterification product into the polymerization device, add the propylene glycol solution of the phosphoric acid ester prepared above, then add the catalyst, stabili...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com