Inherently safe, nuclear proliferation-proof and low-cost nuclear energy production method and device

An inherently safe, nuclear energy production technology, applied in nuclear power generation, nuclear engineering, reactors, etc., can solve problems such as misjudgment and processing by operators, difficult energy market, core melting, etc., and achieve low-cost effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

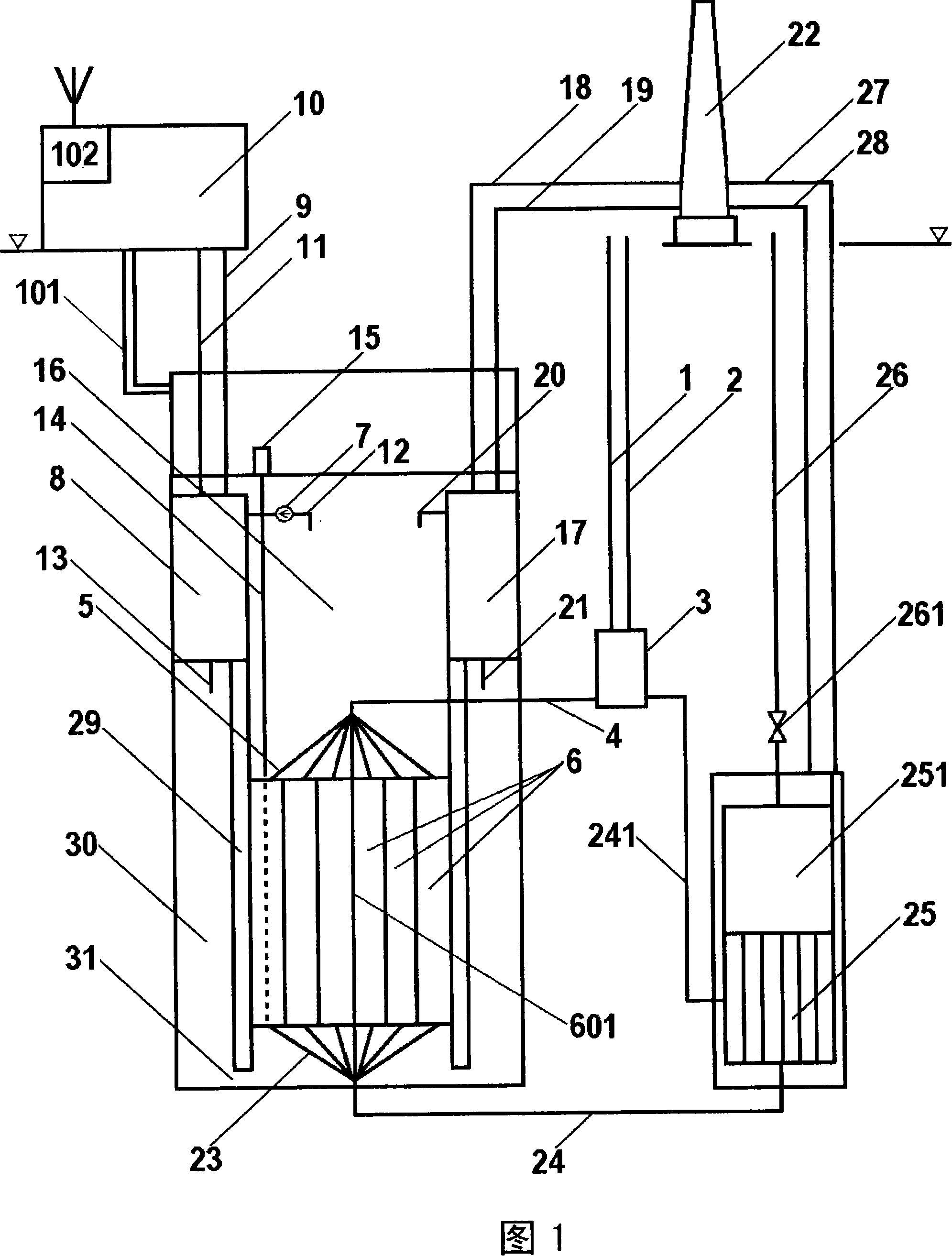

[0083] Fig. 1 shows the process system diagram of the genuine inherently safe, non-proliferation, and low-cost nuclear energy production method and device proposed by the present invention.

[0084] The nuclear energy production method shown in Figure 1 adopts the following process steps in a fully automated quasi-liquid fuel reactor process: the coated nuclear fuel particles (hereinafter referred to as "coated particles") are mixed with a certain proportion of high-boiling point heat carrier to produce A kind of liquid-like nuclear fuel with a certain flow capacity (hereinafter referred to as "quasi-liquid fuel"); the quasi-liquid fuel is divided into a bunch of fuel boxes to form the reactor core: start the reactor: increase power operation: non-stop The stack is continuously refueled; the depleted quasi-liquid fuel with a low burnup degree discharged from each fuel box is recycled back to the core for reuse; the "spent fuel" that has reached the deepest burnup level is sent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com