High-speed movable bearing in particular for the mounting of a main spindle of a machine tool

A floating bearing, high-speed technology, applied in the direction of rolling contact bearings, ball bearings, shafts and bearings, can solve the problems of material damage, low load capacity, complete failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

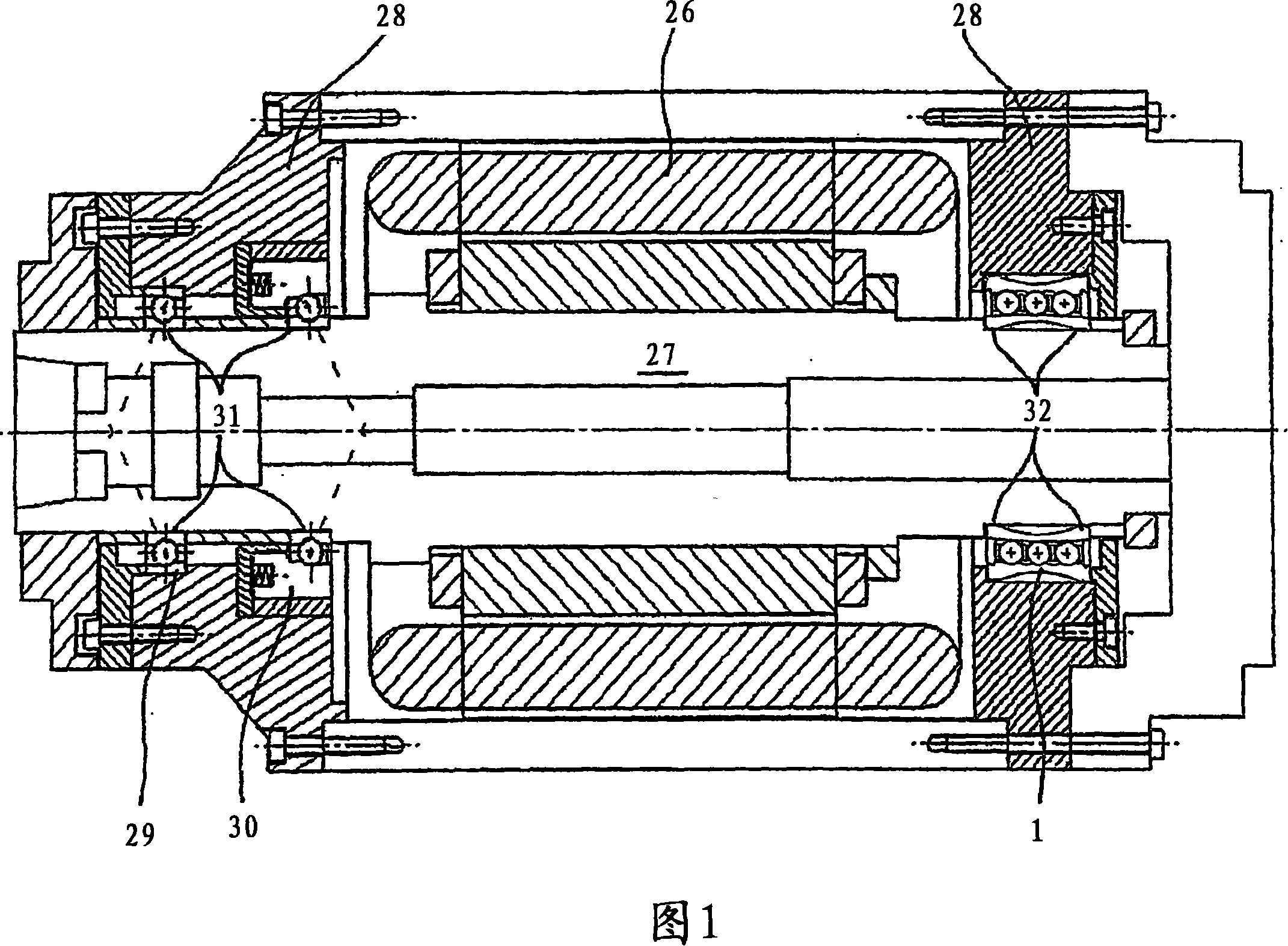

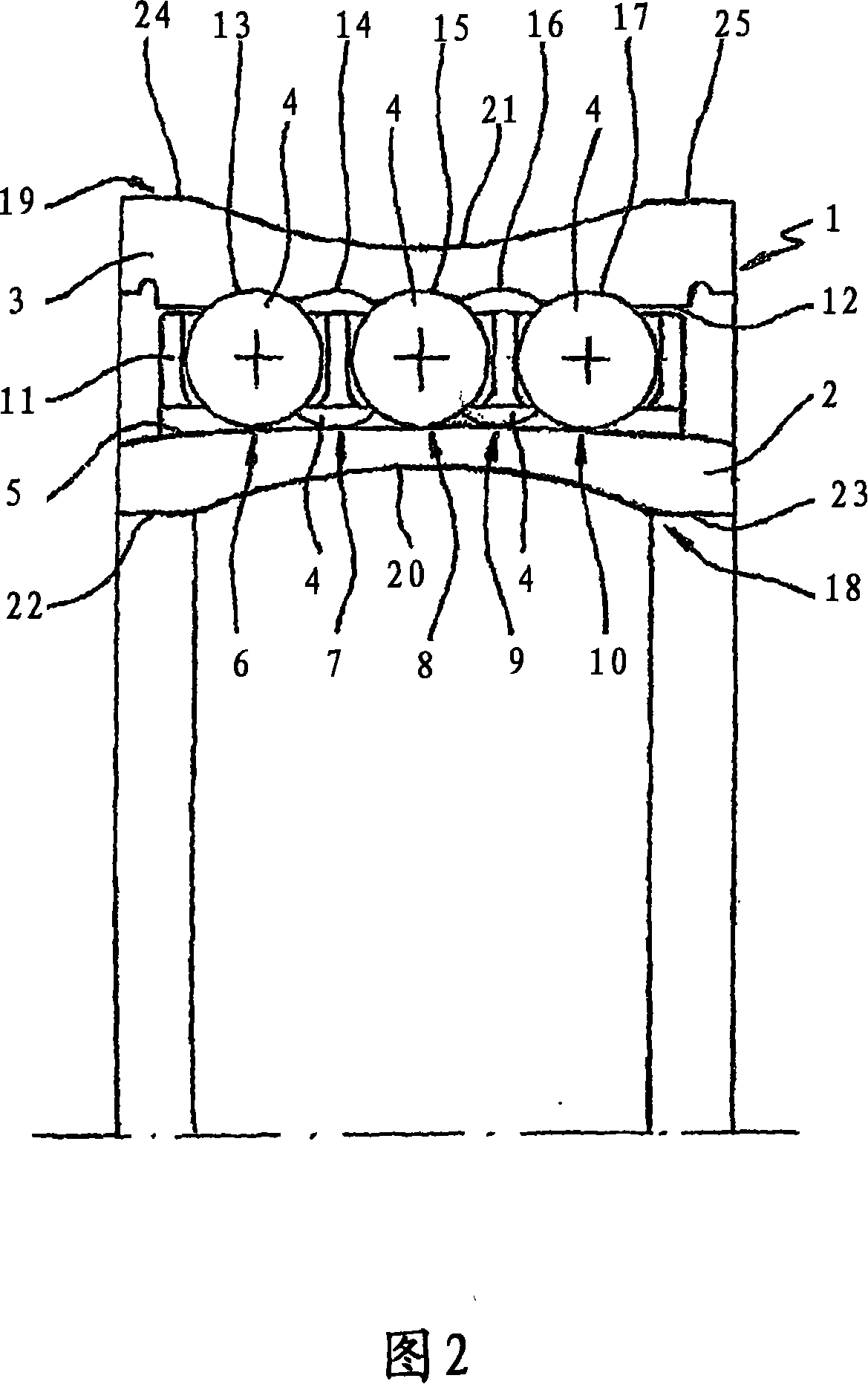

[0017]FIG. 1 shows schematically a drive for a processing machine tool, which essentially comprises an electric motor 26 and a spindle 27 driven by the motor. The main shaft 27 is visibly mounted at one end in two angular contact ball bearings 29 , 30 which are formed as fixed bearing seats 31 in the main shaft housing 28 . The other end of the main shaft 10 is supported in a floating bearing seat 32 which is formed by the high-speed floating bearing 1 according to the invention. For this reason, it can be seen from FIG. 2 that the high-speed floating bearing 1 basically includes an inner bearing ring 2 fixed on the main shaft 27, an outer bearing ring 3 fixed in the main shaft housing 28, and some bearing rings 2 arranged on the bearing ring 2. , 3 between the rolling elements 4 and has the possibility to function as a floating bearing, that is, the axial movement of the inner bearing ring 2 in the area of its rolling surface 5 for the rolling elements 4 .

[0018] Further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com