Method for processing printed circuit board waste and resource reusing

A technology for printed circuit boards and wastes, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. , The effect of reducing production costs and enriching economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further illustrated below through the embodiments in conjunction with the accompanying drawings.

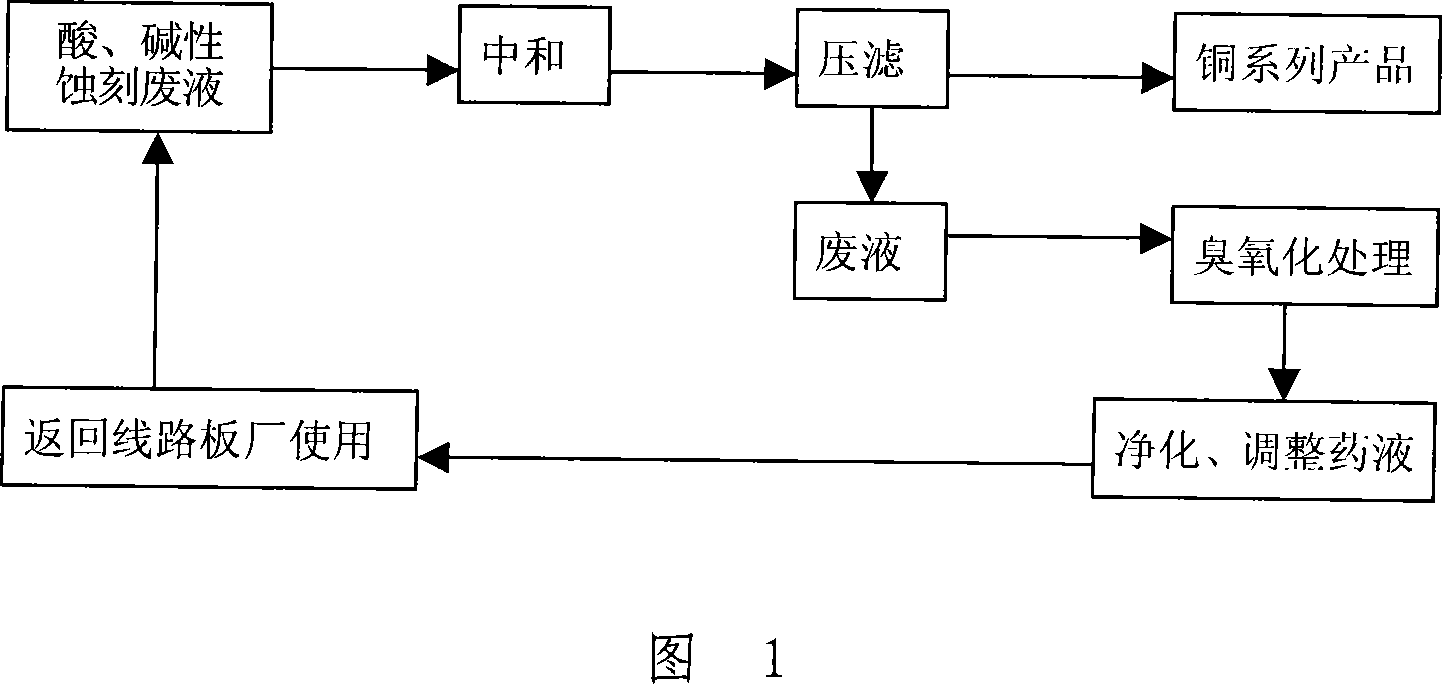

[0020] Fig. 1 is the flow chart of the recycling of etching waste liquid in the present invention, and its basic process is to neutralize acid and alkaline etching waste liquid, and press filter the neutralized waste liquid to obtain copper-containing products, which are obtained by press filtration The waste liquid is subjected to ozonation treatment, and then the treated waste liquid is purified, and the composition of the new etching liquid is adjusted according to the composition of the new etching liquid to obtain the new etching liquid.

[0021] Use ozone as an oxidant to regenerate the etching waste liquid of printed circuit boards. The metals in the waste liquid are separated and refined to make basic chemical raw materials, and the regenerated etching waste liquid becomes new etching liquid and returns to PCB manufacturers for use, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com