Ground pit type high-heat aerobic organisms fermentation odour remover and method for degradation of organic effluvial waste dump fertilizer

A biological fermentation and aerobic biological technology, applied in the preparation of organic fertilizers, the treatment of biological organic parts, organic fertilizers, etc., can solve the problems of organic waste pollution and other problems, and achieve the effect of saving energy consumption and sufficient oxygen supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

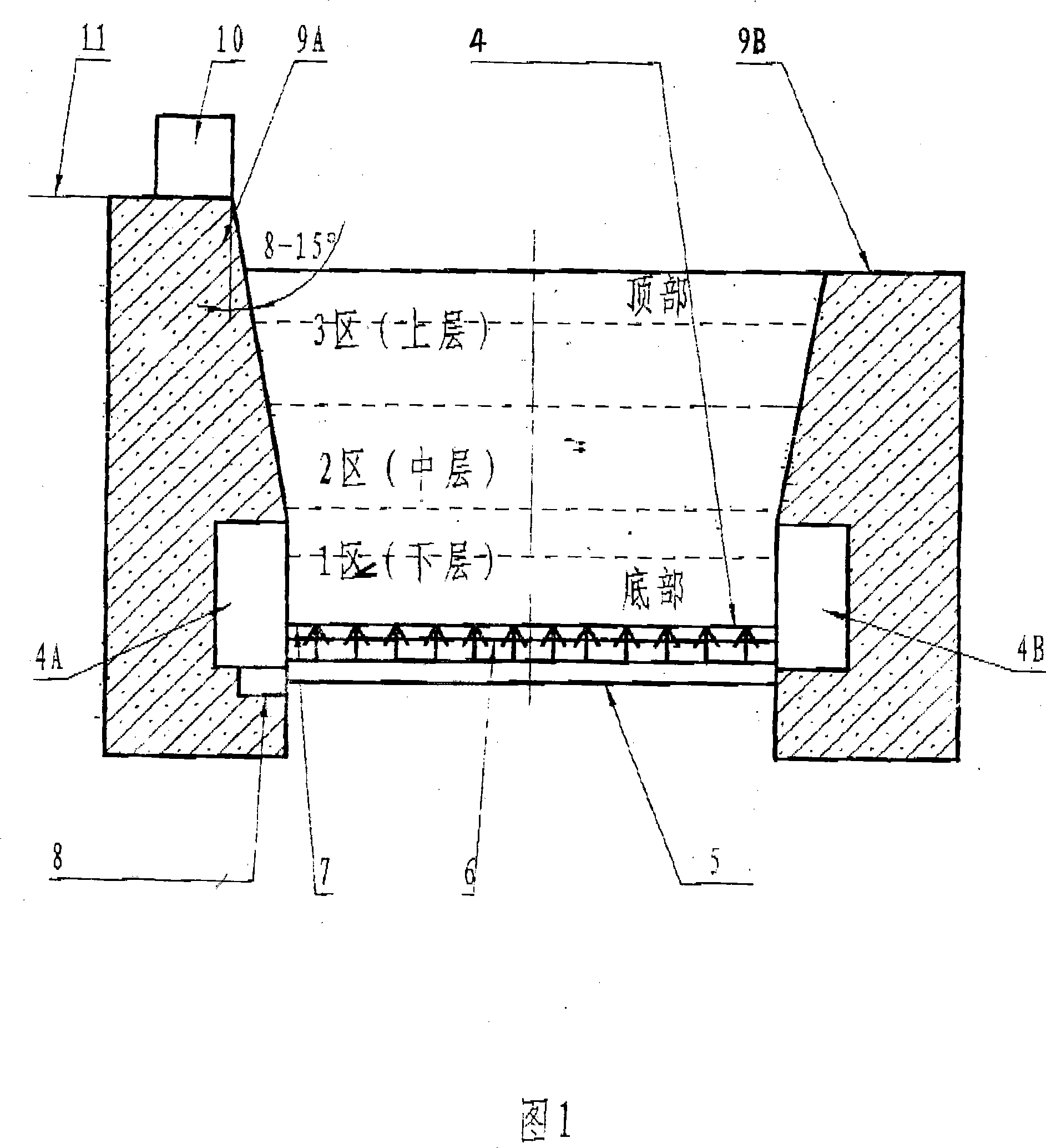

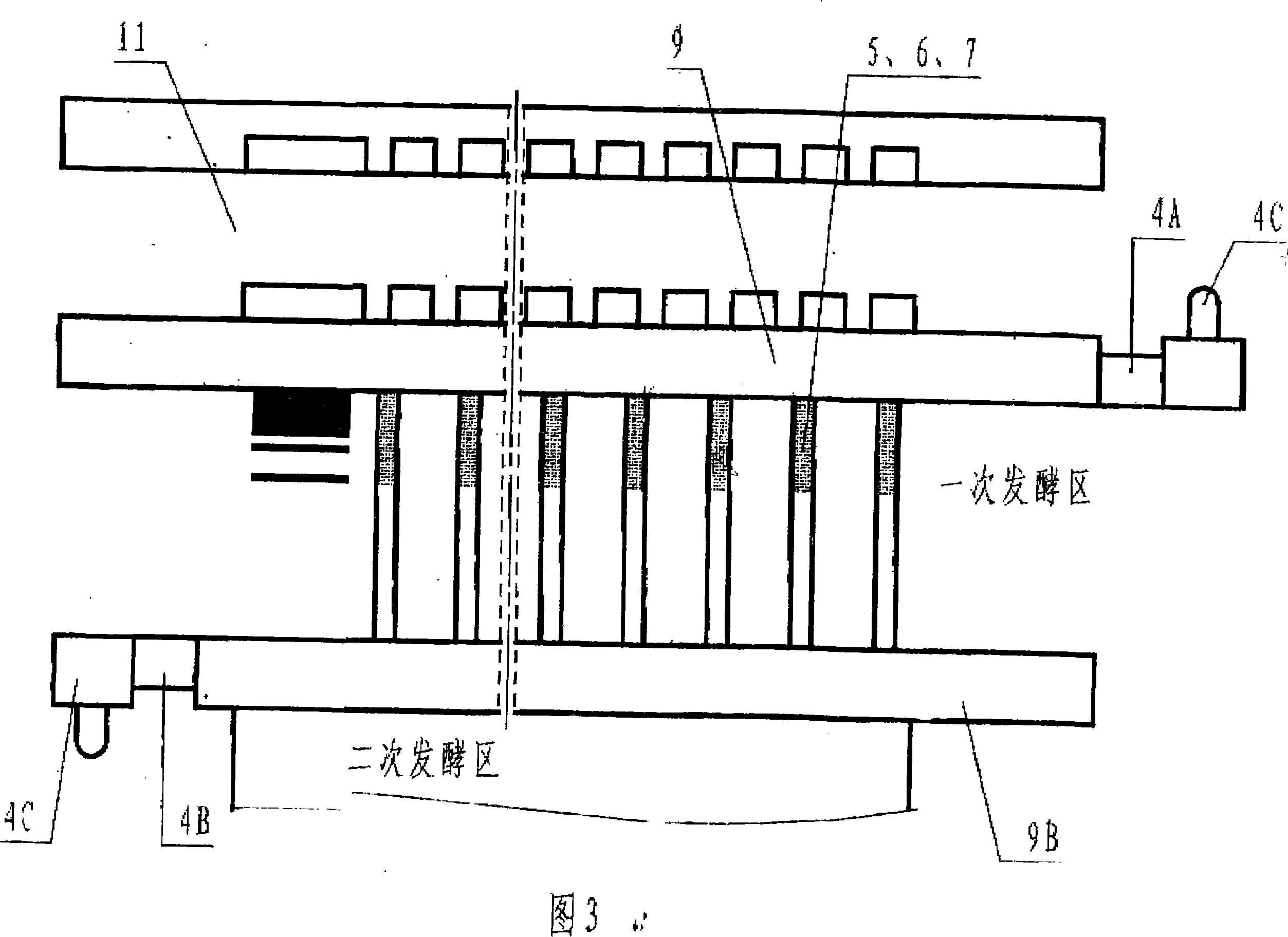

[0097] Example 1: A pit type high temperature aerobic biological fermentation deodorizer, with a daily treatment of 430m 3 Take organic waste as an example. First, set up two adjacent pits, which are the first biological fermenter and the second biological fermenter. The length is 53m, the width is 15m, the wall height is 2.25m, and its bottom surface is 3 meters above the ground. , to prevent rainwater from pouring back, and dozens of ventilation and oxygen supply ditches 5 are arranged on the bottom surface, and each ventilation and oxygen supply ditch is equipped with 50 ventilation and oxygen supply pipes 6, and the two ends of the ventilation and oxygen supply pipes 6 are connected to the inner sides of the walls 9A and 9B on both sides. The layout is 100mm wide, 400mm high, and 50m long. The rectangular main air ducts 4A and 4B are connected. The main air ducts are respectively connected to two fans 4C. The fan power is 11KW and the air volume is 15000m 3 / h, wind press...

Embodiment 2

[0129] Embodiment 2: A pit type high temperature aerobic biological fermentation deodorizer, with a daily treatment of 430m 3 Take organic waste as an example. First, set up two adjacent pits, which are the first biological fermenter and the second biological fermenter. The length is 53m, the width is 15m, the wall height is 2.25m, and its bottom surface is 5 meters above the ground. , to prevent rainwater intrusion. Dozens of ventilation and oxygen supply ditches 5 are arranged on the bottom surface, and each ventilation and oxygen supply ditch is equipped with 150 ventilation and oxygen supply pipes 6. The 50m-long rectangular main air ducts 4A and 4B are connected, and the main air ducts are respectively connected to two fans 4C, with a fan power of 40KW and an air volume of 50,000m 3 / h, the wind pressure is 2500Pa, and the fans are used to ventilate and supply oxygen to the main air pipe 4 respectively. The fans are controlled by the PLC computer and the frequency conve...

Embodiment 3

[0160] Example 3: A method for degrading the stench of organic malodorous waste using a pit-type mesophilic aerobic biological fermentation deodorizer, with a daily treatment of 430m 3 Taking organic waste as an example, first, set up the above-mentioned biological fermentation deodorizer, the specific steps are as follows:

[0161] (1) The dump truck will use the potential difference from the elevated road to unload the biologically pretreated materials directly onto the bottom surface of the fermenter, pile them up along the wall into a 0.4-1.2m high oblique triangle pile, and unload the materials one by one , until it is full; or use a dump truck to directly drive into the bottom surface of the first biological fermenter, and unload and pile up into strips one by one;

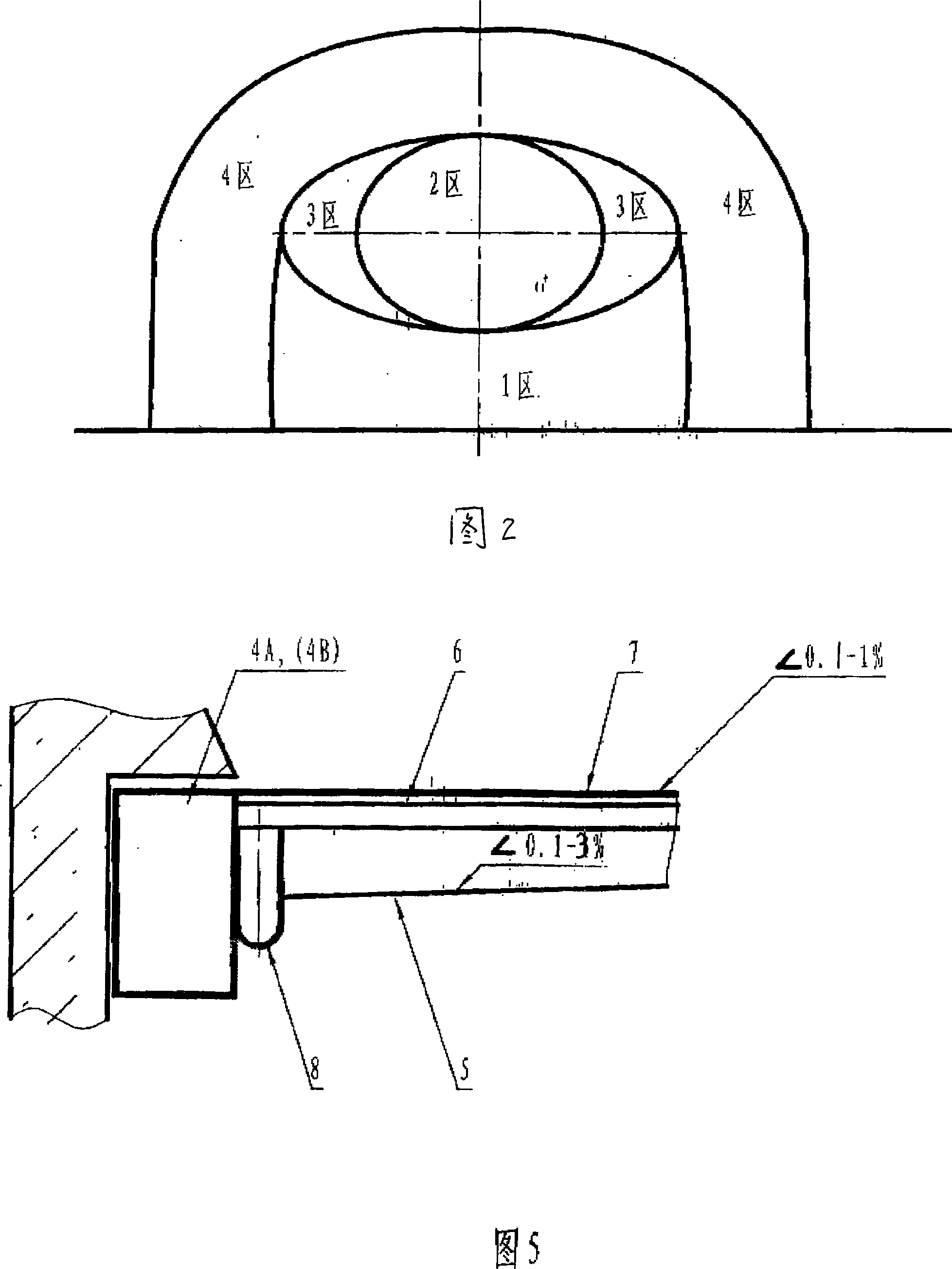

[0162] (2) Divide the biological fermenter into three sections, the first section is 0-4m, the second section is 4-7.6m, the third section is 7.6-10.8m, and the bucket and arm length of the special compostin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com