Thermal contracting polyester film and method for preparing same

A polyester film and heat shrinking technology, applied in the field of heat shrinkable polyester film, can solve the problems of unsuitable heat shrinkage modification, reduce crystallization rate, etc., and achieve excellent heat shrinkage effect, low cost, and cost reduction effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

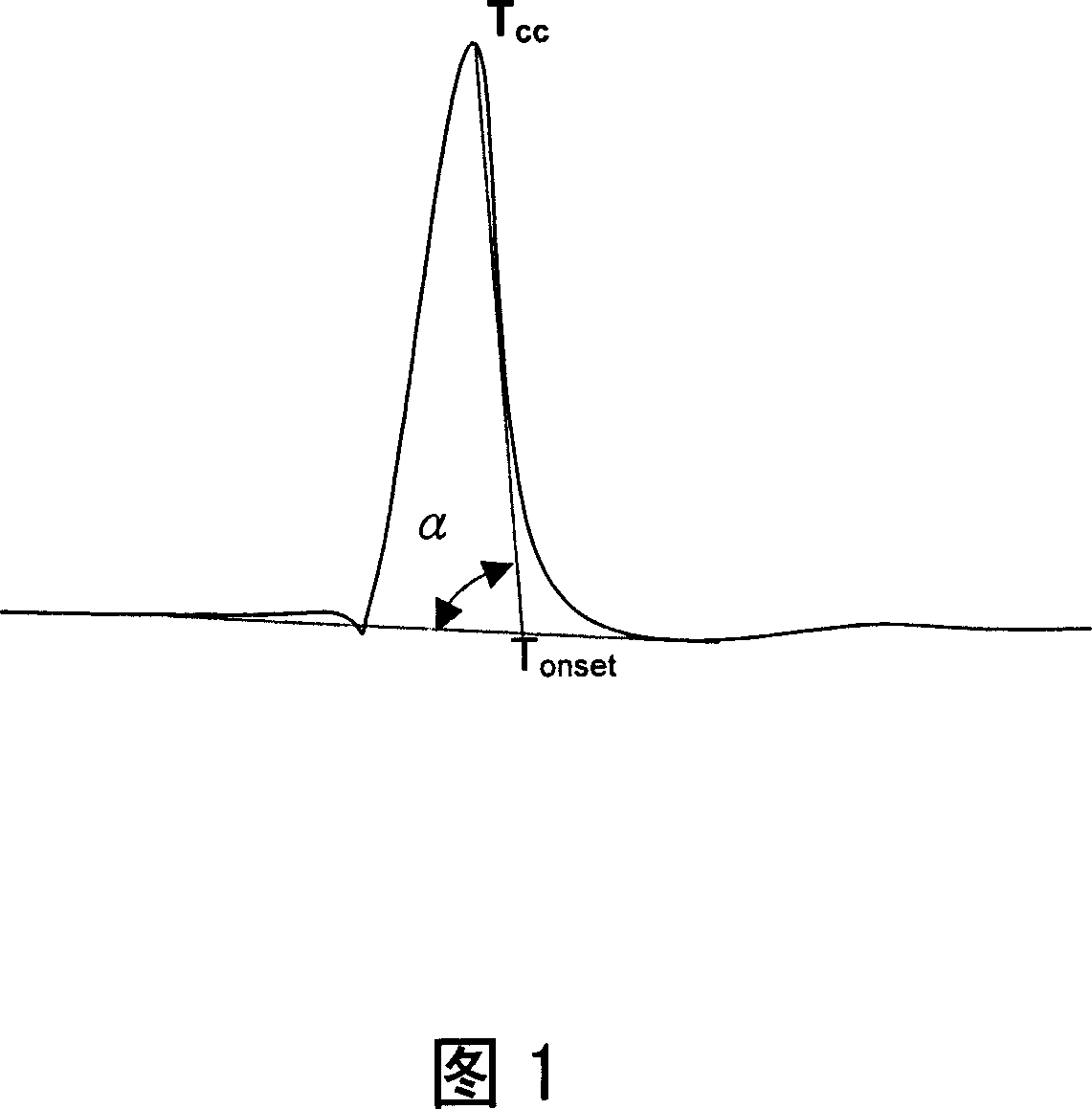

Image

Examples

Embodiment 1

[0068] I. Preparation of Modified Copolyesters

[0069] Pour terephthalic acid, ethylene glycol, and 1,3-dihydroxy-2-methylpropane in a molar ratio of 1:0.998:0.249 into a stirring tank and stir to form a paste, and add 75ppm of heat stabilizer ( Phosphoric acid), and then pour the paste into the esterification tank, heat up and stir, and carry out the esterification reaction at the same time, which lasts 6 to 7 hours, and the pressure in the tank is controlled at 3kg / cm 2 Within the same time, let the water generated by the reaction be distilled and collected through the rectification tube. The final temperature of the esterification end is 250°C, and then the esterified product in the reaction tank is transferred to the condensation reaction tank, and 300ppm of antimony trioxide and 50ppm of cobalt acetate are added as catalysts, and the temperature is gradually raised to 285°C, and within 2 hours Vacuum to about 1torr. Until the intrinsic viscosity (intrinsic viscosity, I...

Embodiment 2

[0084] I. Preparation of Modified Copolyesters

[0085] The copolyester of the present embodiment is prepared in the same manner as in Example 1, except that the molar ratio of terephthalic acid, ethylene glycol and 1,3-dihydroxy-2-methylpropane is 1: 1.05: 0.20. And the obtained modified PET copolyester has a melting point of 206.52° C. and a crystallization temperature of 133.49° C. in the heating curve.

[0086] II. Production of heat-shrinkable polyester film

[0087] Eight heat-shrinkable polyester film samples were prepared in the same manner as in Example 1, Part II.

[0088] III. Shrinkage test of heat-shrinkable polyester film

[0089] Heat shrinkage test method: Same as the above-mentioned JIS Z1709 standard.

[0090] Test Results :

[0091] As shown in Table 4, except that the shrinkage rate of sample 5 is almost 0 because it is not stretched, the shrinkage rate of the other samples is distributed between 51-67%, which means that the heat shrinkable film of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com