Shockproof conductive polyphenyl ether compound and method for making same

A polyphenylene ether and compound technology, which is applied in the field of conductive polyphenylene ether compound and its preparation, can solve the problems of mechanical properties and processing properties, and achieve the effects of improving mechanical properties, high practical value and excellent mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

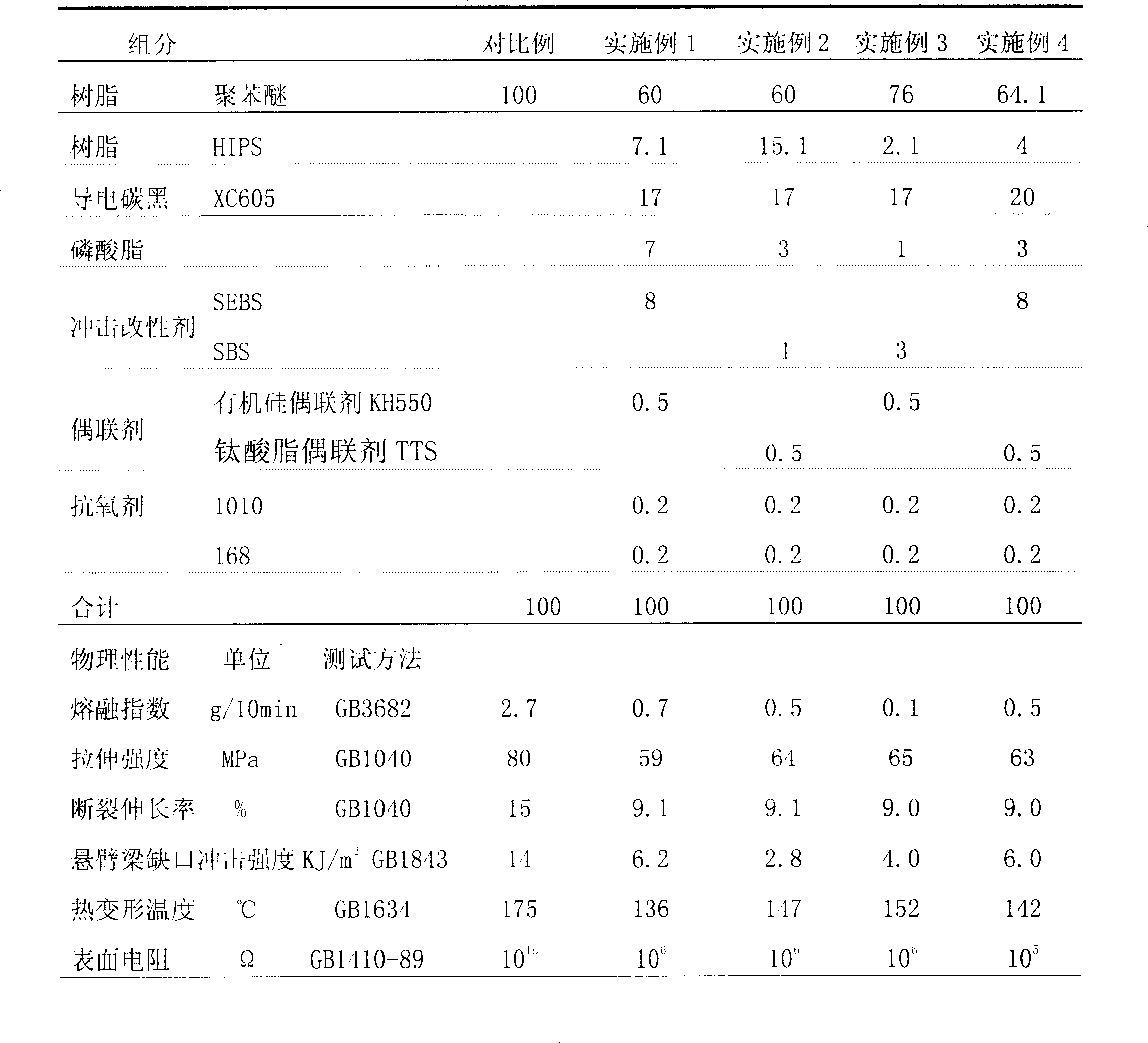

Image

Examples

Embodiment Construction

[0017] The preparation steps of the impact-resistant conductive polyphenylene ether compound of the present invention are:

[0018] Adopt high-speed pre-mixing and dispersing one-time extrusion process. First, the polyphenylene ether resin, high impact polystyrene, phosphate ester, impact modifier, antioxidant, coupling agent and other additives are dispersed and mixed by a high-speed mixer, and then directly enter the twin-screw extruder for processing. The black is processed by side feeding into the twin-screw extruder, extruded, cooled, dried, pelletized and packaged. The temperature of each partition of the screw barrel should be kept at 240-270°C. The aspect ratio of the twin-screw extruder is 38, and the screw speed is 400 rpm.

[0019] According to the above preparation method, in this embodiment, polyphenylene ether is used as polyphenylene ether with a characteristic viscosity of 0.40dl / g, HIPS with a butadiene rubber content of 3-10%, and the carbon black is XC605,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com