Built-in rotating machinery operation monitoring protecting equipment and setting method thereof

A technology for rotating machinery and protection devices, applied in the field of rotating machinery operating conditions and intelligent monitoring and protection devices, embedded instruments and settings, can solve the problems of heavy software and hardware development workload, and achieve improved anti-interference performance and reduced prices. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

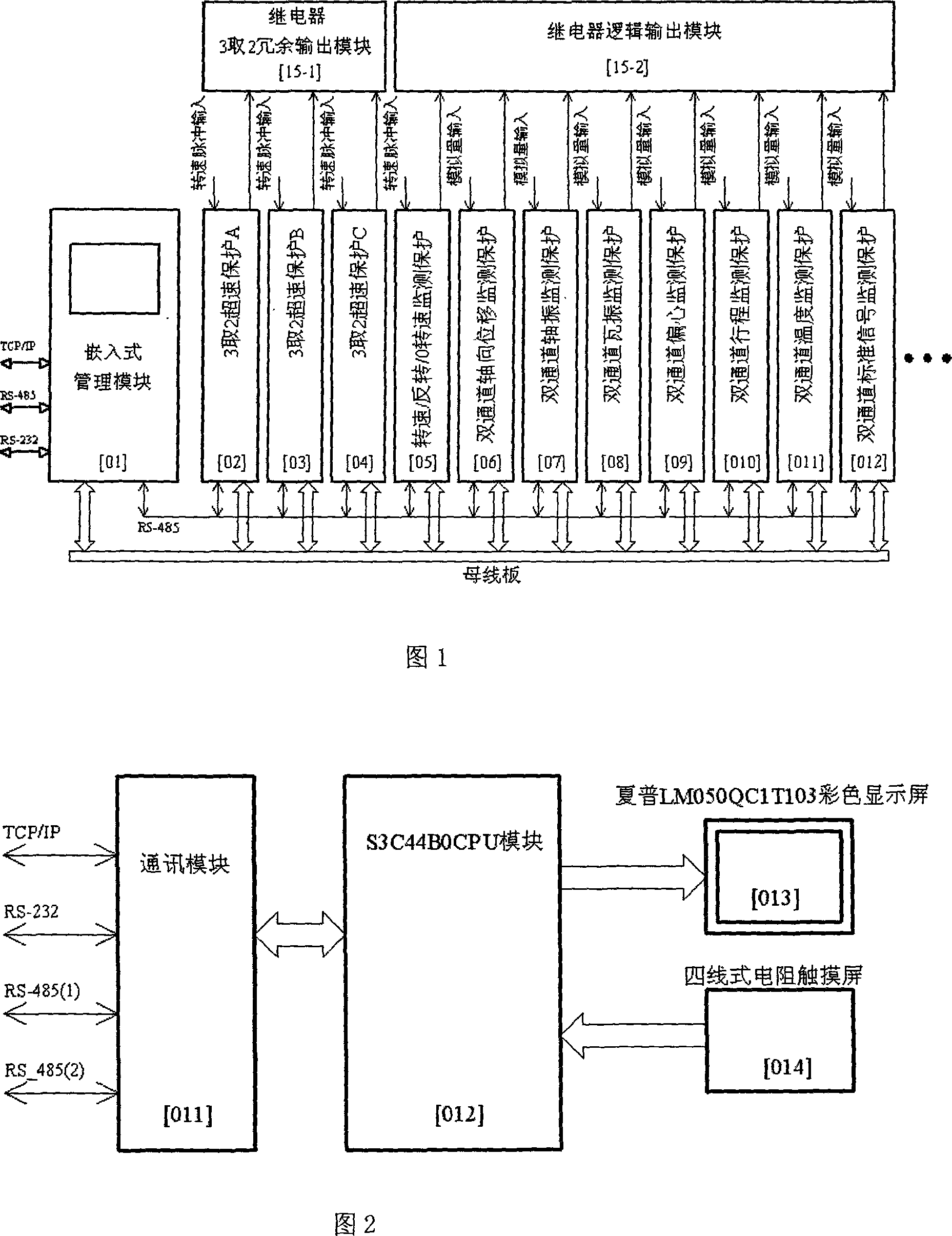

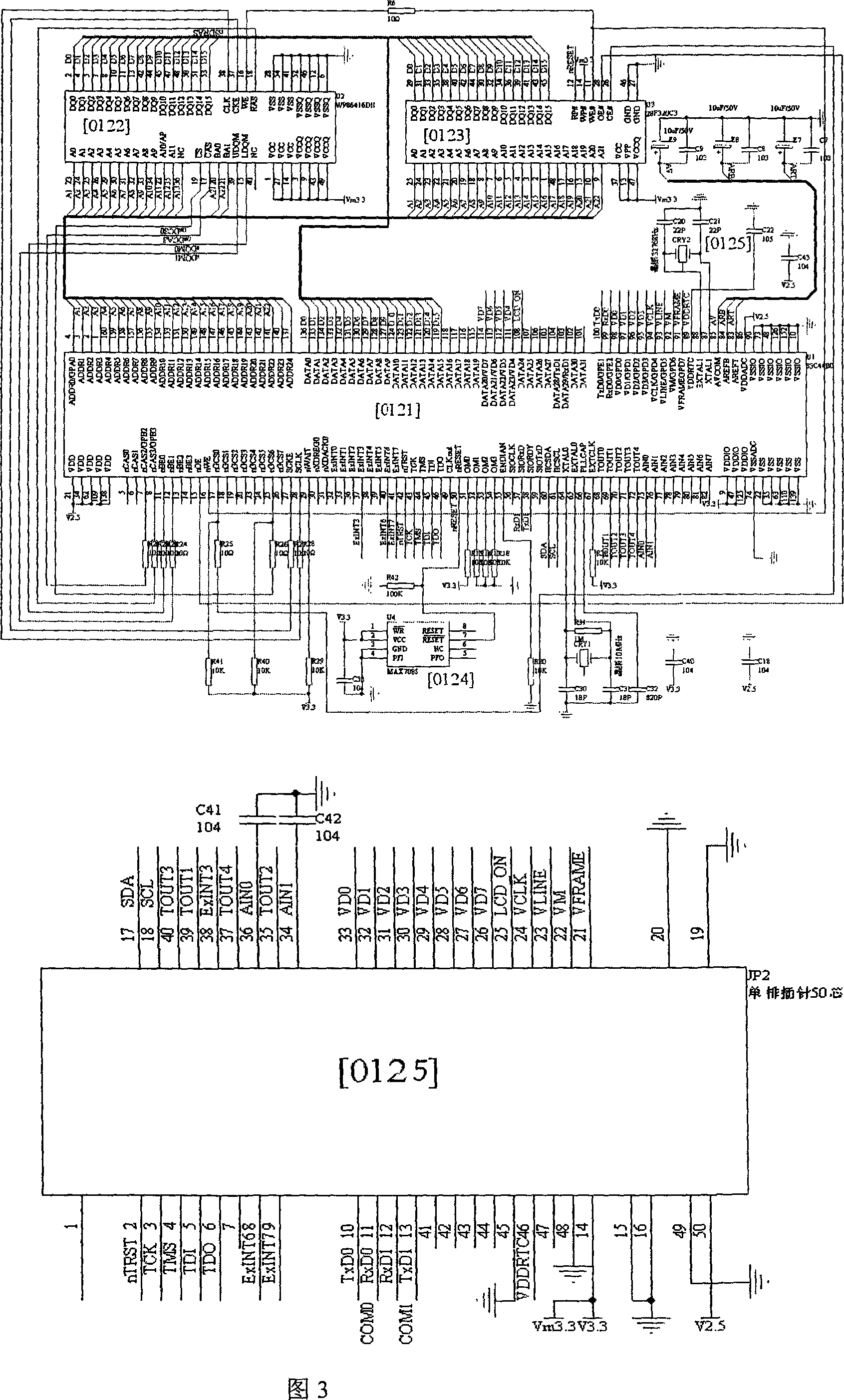

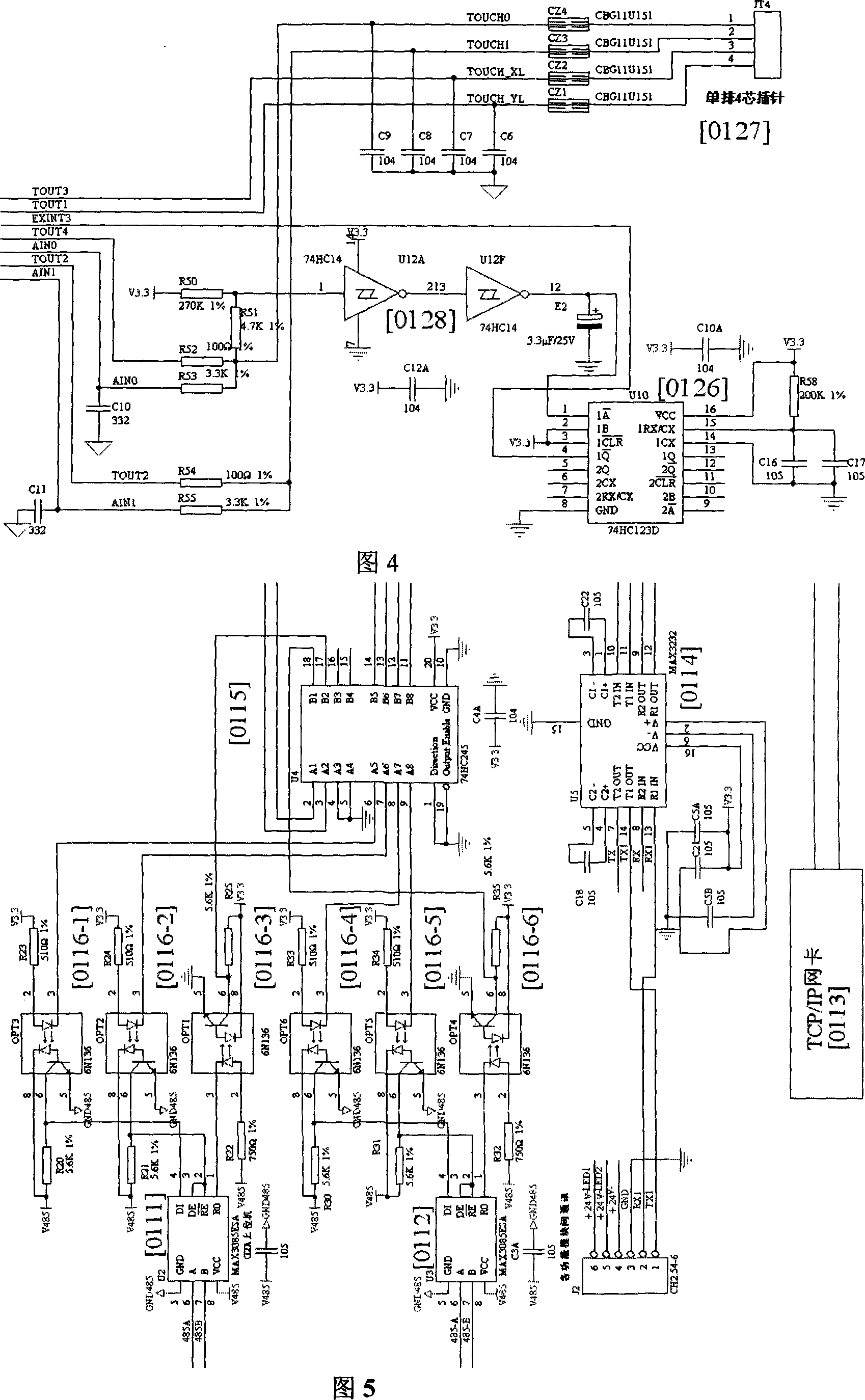

[0047] Embodiment of the setting method of the present invention: mark description in the figure: Fig. 3 has explained management module S3C44B0 embedded CPU module 012; Wherein: processor 0121, dynamic read-write memory SDRAM0122, FLASH solid-state disk 0123, power monitoring 0124, CPU module socket Pin 0125; Figure 4 management module touch screen circuit: monostable trigger 126, touch screen connector 127, Schmitt trigger 128; Figure 5 management module communication interface, communication interface RS-485 0112, RS-232 0114 , network card 0113, buffer 0115; Figure 7 function module LPC2114 embedded CPU circuit, embedded processor 111, A / D converter 112; 113-serial E 2 PROM; [114]-power supply monitoring; in the circuit diagram of the dual-channel 4-20mA current output of the functional module in Fig. 9, optocouplers 161, 162; Schmidt triggers 165, 166; multi-way switch 168; Input, wherein: emitter follower 131, 132; low-pass filter 133, 136; amplification and rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com