Processing method of wastewater in the sebacic acid production and special extractor thereof

A wastewater treatment and extraction device technology, which is applied in the direction of processing wastewater treatment, extraction water/sewage treatment, neutralization water/sewage treatment, etc., can solve the problems of short resin use cycle, heavy backwashing workload, and large resin consumption and other issues to achieve the effect of reducing processing costs, improving production levels, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

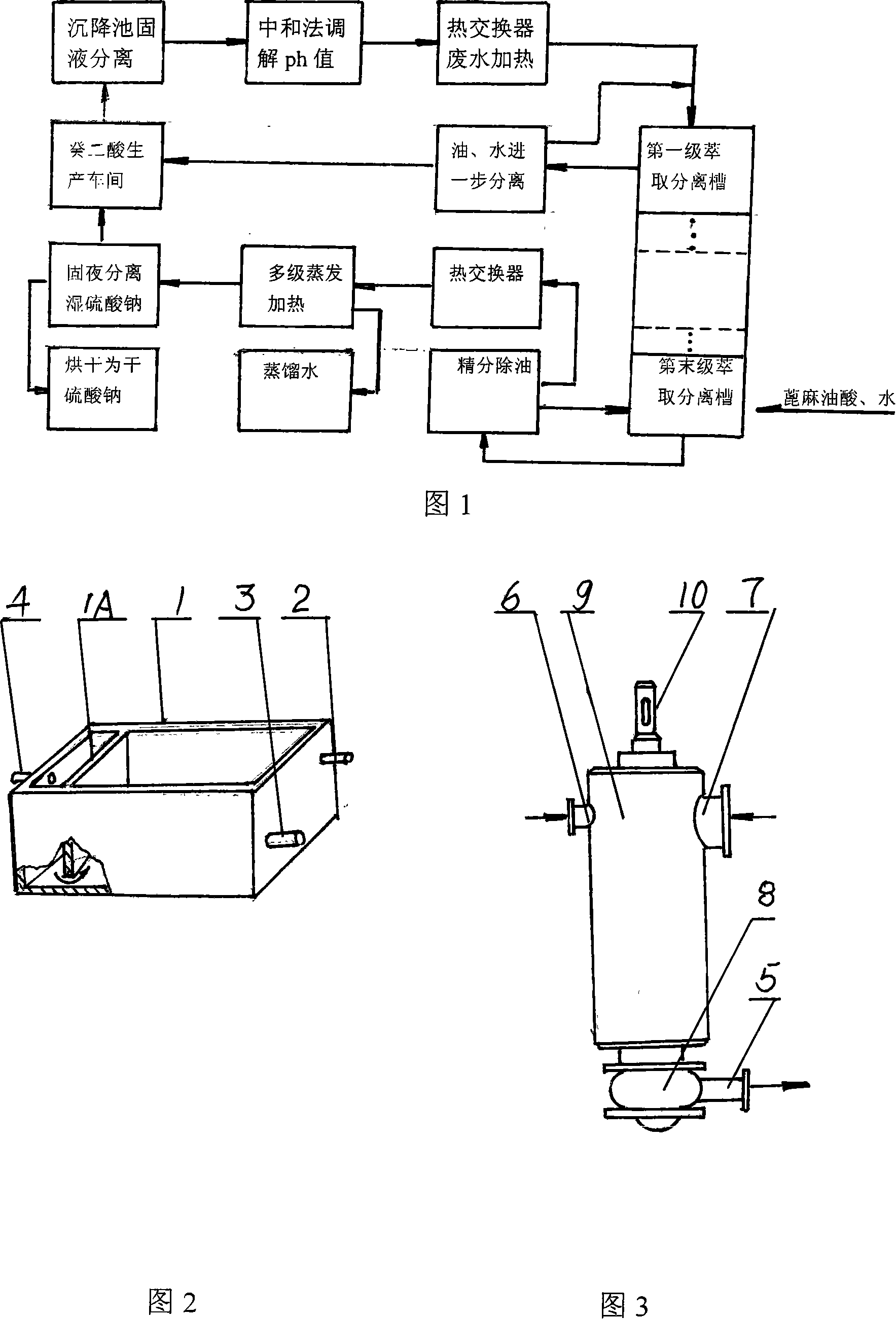

[0016] It can be clearly seen with reference to the drawings that the core of the present invention is to use ricinoleic acid as the extractant of the main forbidden phenol, to provide a practical treatment method, and to provide an ideal dedicated multi-stage extraction tank device.

[0017] The treatment method includes solid and liquid separation in the sedimentation tank, pH adjustment by the neutralization method, extraction of the forbidden material by the extractant, and separation of the forbidden material from the discharged water. The key is that the method uses ricinoleic acid as the extractant to extract and separate Sebacic acid is used to produce the banned phenol in wastewater, and the specific steps of mixing the extractant and the extract are used for repeated use.

[0018] In the following specific implementation instructions, reference is made to the relevant technical conditions given by the amount of wastewater generated under a production scale of 1-2 tons / ye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com