High-voltage static atomizing preparing technique for nano-grade cellulosic material

A technology of nano-scale cellulose and high-voltage electrostatic spraying, which is applied in fiber raw material processing, textiles and papermaking, etc., can solve the problems that nano-scale cellulose materials have not been reported, and achieve the effect of simple preparation method and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] a. Put 2 parts of wood pulp cellulose (commercially available product) and 48 parts of ionic liquid AMIMCl in a flask, heat it in a constant temperature oil bath at 80°C, stir at high speed (600rpm), wait until the cellulose is dissolved, and become transparent amber To dilute the cellulose solution, 50 parts of dimethylformamide (DMF, Beijing Chemical Factory, analytical grade) were added to dilute the ionic liquid solution of cellulose. The process can be carried out under normal pressure. (AmimCl is 1-allyl-3-methylchloroimidazole, prepared by the method described in the literature "Acta Polymerica Sinica, 2003, 3:448-451" by Ren Qiang, and N-methylimidazole And allyl chloride into a three-necked flask, filled with N 2 Protect, heat to reflux in an oil bath at 60°C while stirring. Stop the reaction after 7 hours, use a rotary evaporator to evaporate excess allyl chloride, and cool to room temperature; use ether as the extractant, apply vigorous stirring, extract and remo...

Embodiment 2

[0028] a. Put 1 part of wood pulp cellulose (commercial product) and 99 parts of ionic liquid AMIMCl in a flask, heat in a constant temperature oil bath at 80°C, stir at high speed (600rpm) until the cellulose is dissolved and the system is transparent Amber solution. The process can be carried out under normal pressure.

[0029] b. Add the solution to a 10mL injection needle, use a 16# needle, control the voltage at 30kV, and a receiving distance of 15cm. Use aluminum foil for the receiving plate and acetone for the coagulation bath. After receiving, the system is a transparent and colorless suspension with nanofibers. The average diameter of the plain material is 800nm.

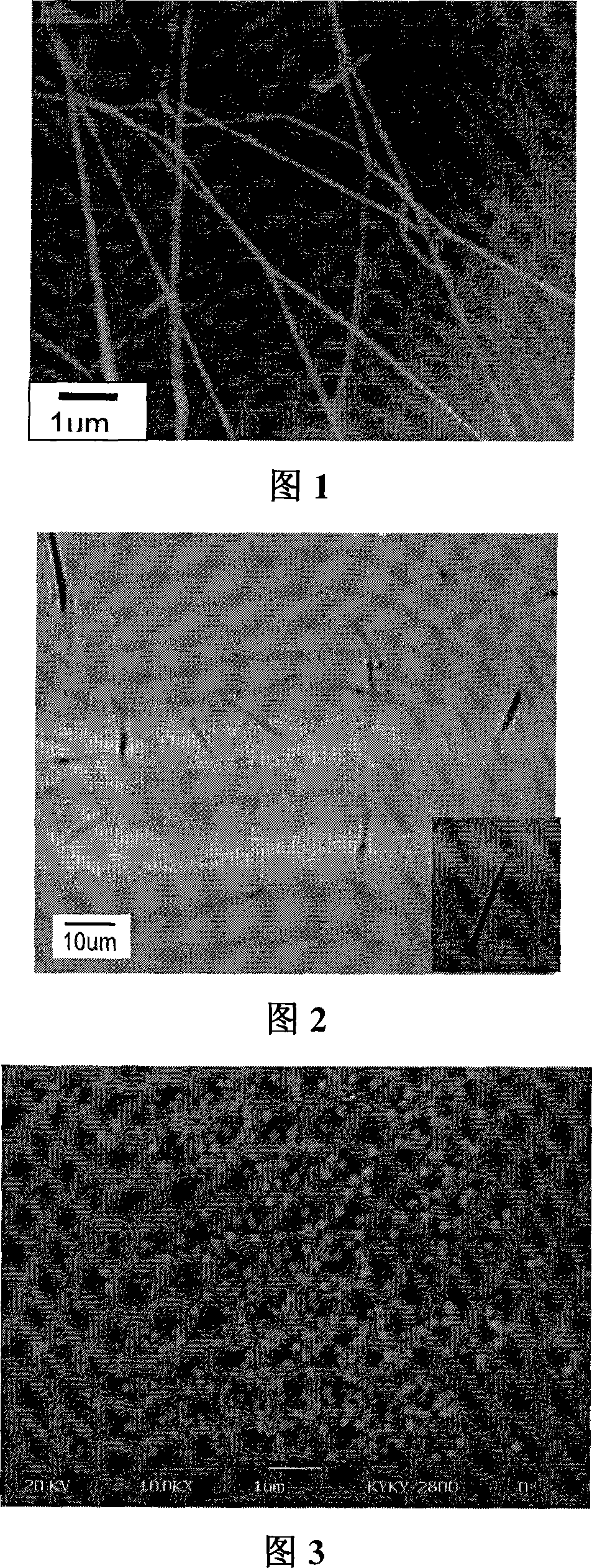

[0030] c. Use filtration and screening methods to separate the nano-cellulose material from the coagulation bath, and then recover the solvent. The electron microscope photo is shown in Figure 2.

Embodiment 3

[0032] a. Put 2 parts of wood pulp cellulose (commercial product) and 98 parts of ionic liquid AMIMCl in a flask, heat in a constant temperature oil bath at 80°C, and stir at high speed (600rpm) until the cellulose is dissolved and the system is transparent. Amber solution. DMF is added to dilute the ionic liquid solution of cellulose. The process can be carried out under normal pressure.

[0033] b. Add the solution to a 10mL injection needle, use a 16# needle, control the voltage at 30kV, and receive a distance of 15cm. Use aluminum foil for the receiving plate and water for the coagulation bath. After receiving, the system is a transparent and colorless suspension with nanofibers. The average diameter of the plain material is 200nm.

[0034] c. Use filtration and screening methods to separate the nano-cellulose material from the coagulation bath, and then recover the solvent. The electron microscope photo is shown in Figure 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com