Target surface focal spot monitoring device

A monitoring device and a target surface technology, applied in the field of targeting systems, can solve the problems of small magnification of long focal length microscopes, inability to truly reflect the focal spot condition, low measurement accuracy of the focal spot on the target surface, etc., and achieve convenient optical axis docking and structure Compact, high-precision adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

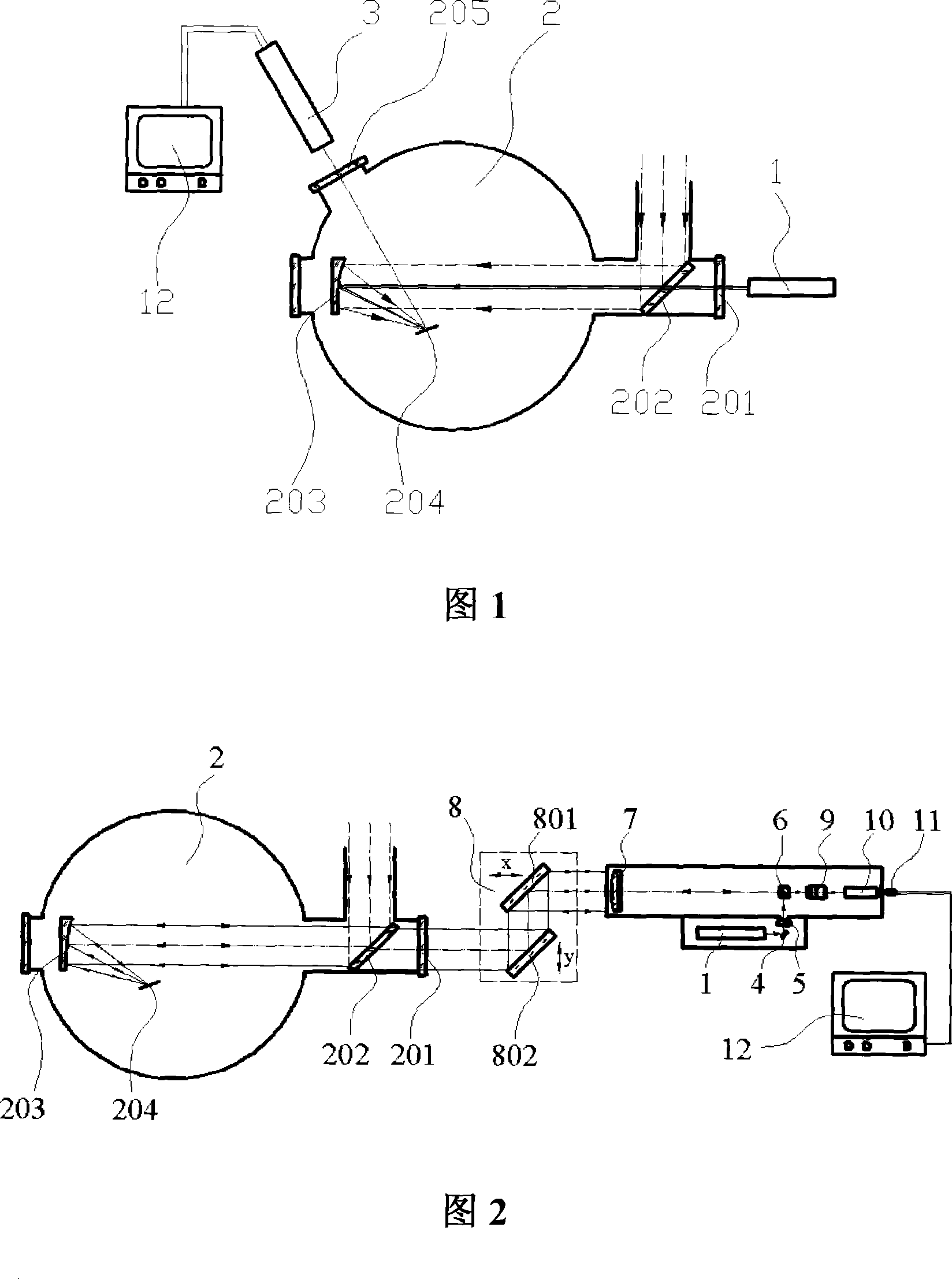

[0024] Please refer to FIG. 2 . FIG. 2 is a schematic structural diagram of the target surface focal spot monitoring device of the present invention. It can be seen from the figure that the target focal spot monitoring device of the present invention includes a parallel laser beam emitting optical path, a target imaging optical path, an optical axis docking system and an image receiving system. The parallel laser beam emitting optical path is used to emit an analog beam, and the target surface imaging optical path receives the scattered light emitted by the focal spot of the target surface to image the target surface, and the optical axis docking system realizes the optical axis and the focal spot monitoring device of the present invention. The docking of the optical axis of the target beam, the image receiving system is used to receive the target surface image formed by the target surface imaging optical path and display it on the monitor. By calculating the size of the focal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com