Carbon material electric heating ground film, its making method and installation method

A technology of carbon materials and installation methods, which is applied in the direction of electric heating devices, heating methods, electric heating systems, etc., can solve the problems of difficult search and replacement, high power consumption, and short life of resistance wires, etc., and achieves easy mass production and Promote, prolong service life, and have good environmental protection effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

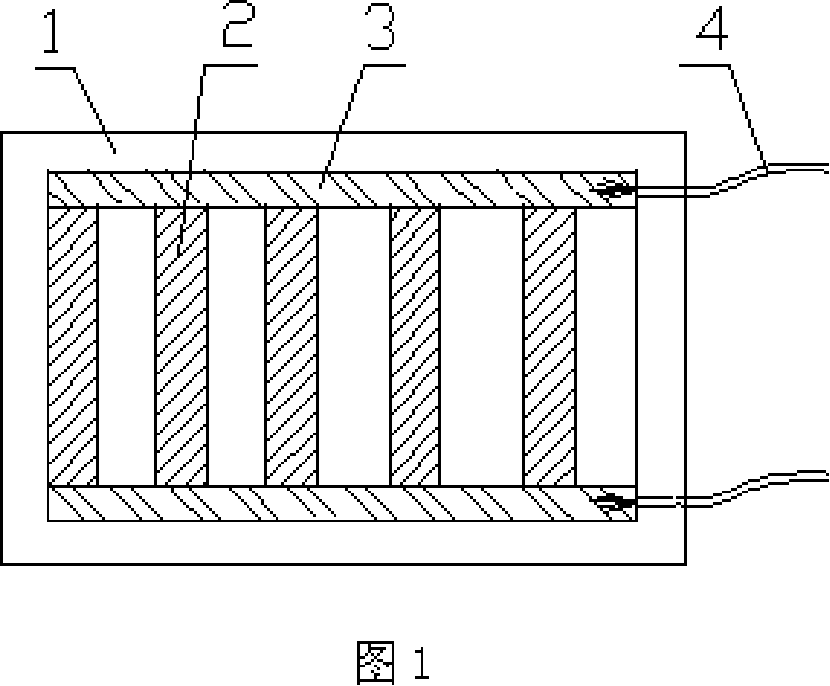

[0024] The electric heating layer in the present invention is the carbon material electric heating film disclosed by the applicant of the present invention in the patent application CN200510200543.9, because the voltage we currently use is 220V, and the heating temperature of the carbon material geothermal film is generally required. In the range of 50 ℃ ~ 55 ℃, carbon material electric heating film with square resistance between 200 and 500Ω is generally selected to produce electric heating film. When manufacturing carbon material electrothermal mulching film, first determine the size and shape of the electrothermal mulching film (taking the production of 600×600mm size electrothermal mulching film as an example), and cut out two polyimide preforms of corresponding size with high temperature resistance and good insulation performance. Melting film 1, in order to ensure the safety performance of the electric heating film, the thickness of the pre-melting film is 0.6mm, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com