Using method and product of water polyurethane used for coating prime glue

A water-based polyurethane and primer technology, applied in the field of water-based polyurethane, can solve the problems of environmental and human health hazards, and high manufacturing costs of solvent-based polyurethane adhesives, and achieve the effects of improving economic benefits, improving comprehensive competitiveness, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

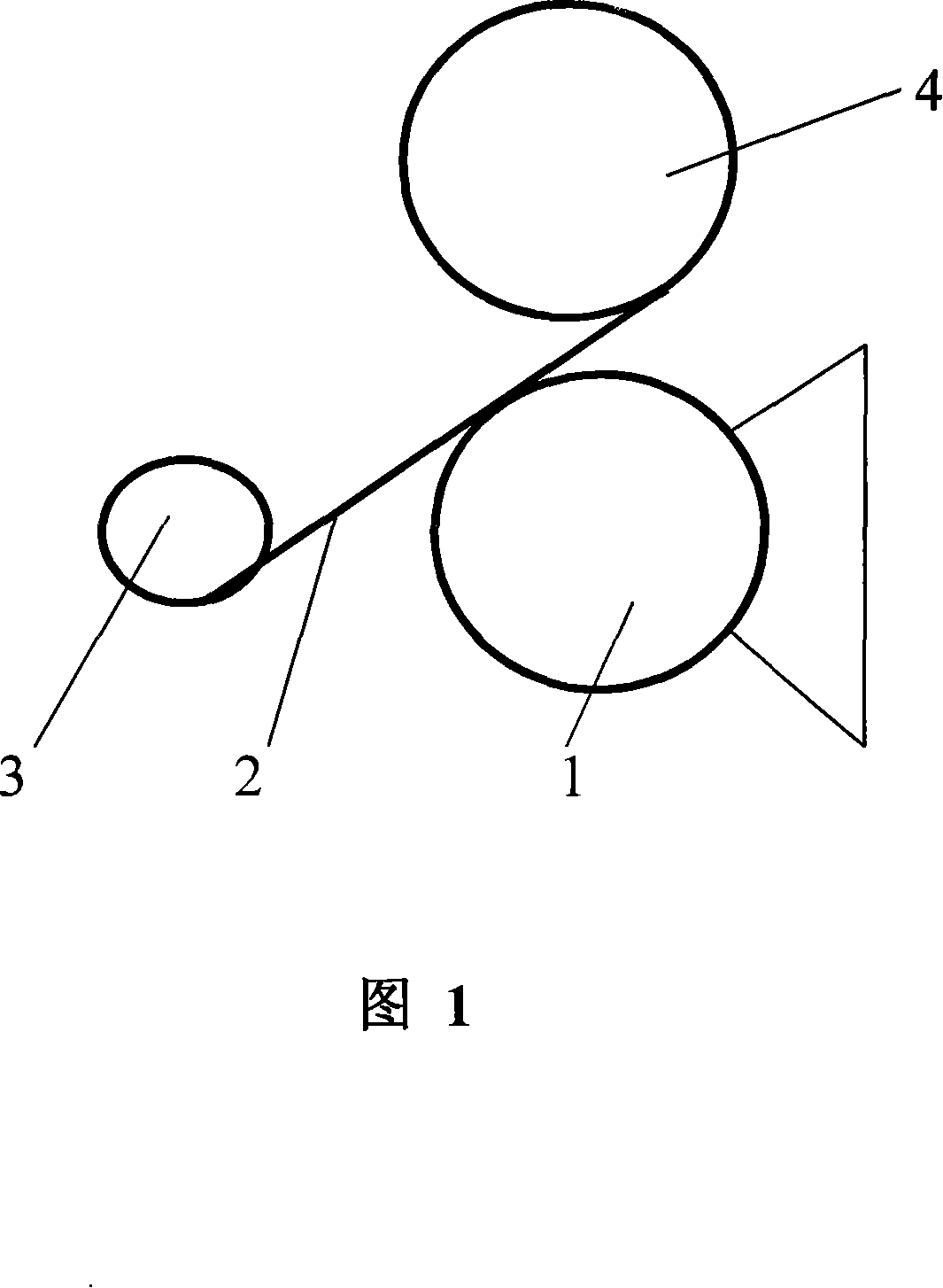

Image

Examples

Embodiment

[0013] Embodiment (1) PVDC coating / primer / BOPP coating film. The substrate film is a BOPP film with a thickness of 19um, and the coating amount of the primer is 0.3g / m 2 , PVDC coating amount is 3.0g / m 2 , Cured at 43°C for 2 days. The coating speed is 200m / min, the drying temperature of the primer layer is 125°C, and the drying time is 6 seconds, and the drying temperature of the PVDC coating is 120°C, and the drying time is 8 seconds. In addition, the primer is dried with hot air, and the top coat is dried with a combination of far-infrared heating and hot air. Coating Material Formula: (1) Primer Coating Material Formula—Weigh 10kg of water-based polyurethane adhesive (55% solid content), 59kg of demineralized water, and stir evenly. (2) PVDC coating material formula for surface coating—weigh 250kg of PVDC emulsion (solid content 49%), 10kg of palm wax slip agent, 1kg of silicon dioxide anti-sticking agent, 30kg of demineralized water, mix and stir evenly.

[0014] Embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com