Paper-making deinking sewage treatment method

A sewage treatment method and treatment method technology, which is applied in the direction of flotation water/sewage treatment, flocculation/sedimentation water/sewage treatment, etc., can solve the problem of high treatment cost, and achieve the effects of reducing treatment cost, reducing impurities, and reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

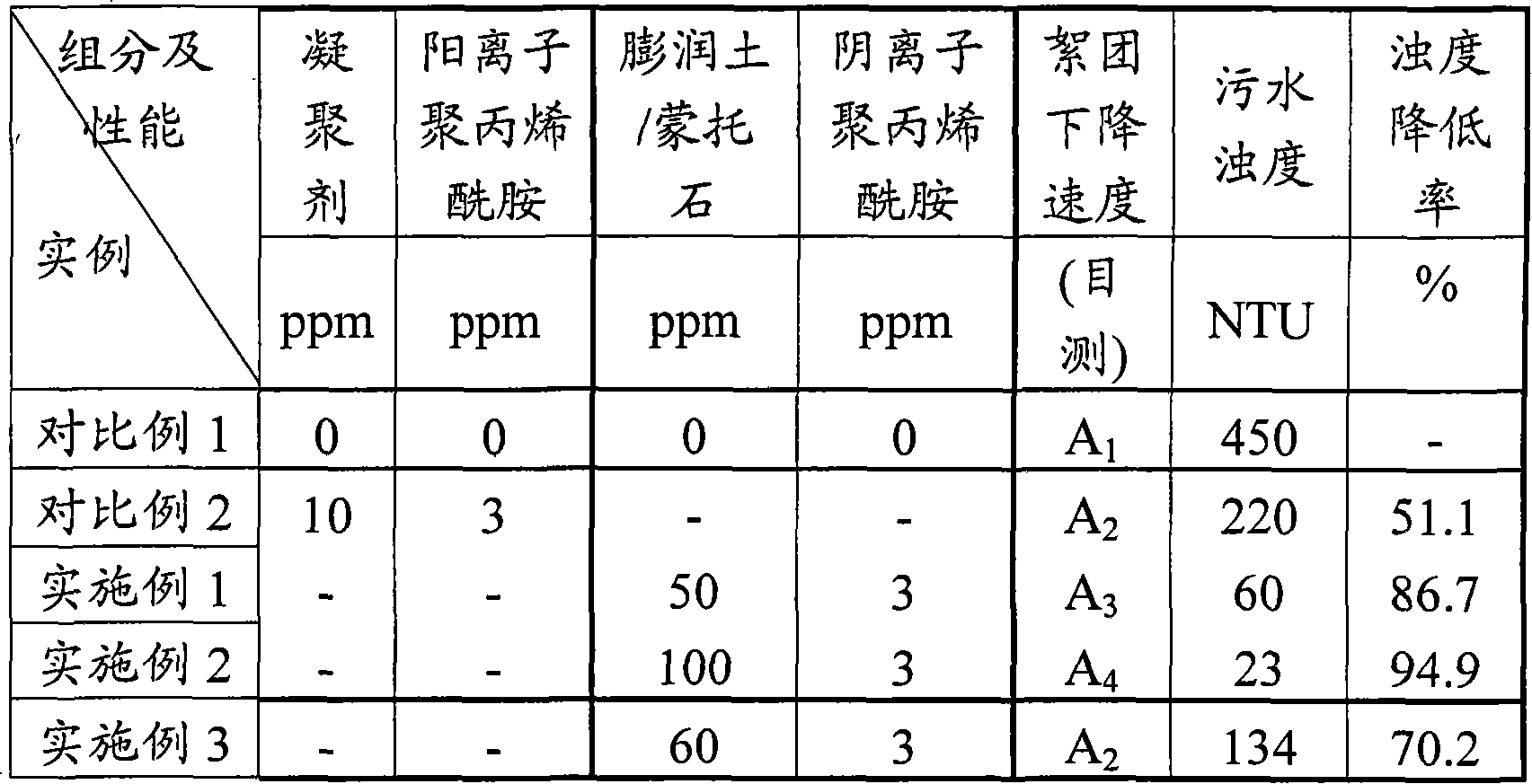

Embodiment 1

[0022] Take a sample of deinked sewage and stir it with a multi-connected mixer in the factory laboratory. Add bentonite to the sewage first, and then add anionic polyacrylamide. The total amount of bentonite in the sewage is 50ppm, and the anionic polyacrylamide in the sewage The total amount added is 3ppm. Observe the size of the flocs and the sinking speed under stirring conditions, and measure the turbidity of the treated water at the same time. The measurement results are shown in Table 1.

Embodiment 2

[0024] Except that the total amount of bentonite added in the sewage is 100ppm, all the other are the same as in Example 1.

Embodiment 3

[0026] Take a sample of deinked sewage and stir it with a multi-connected mixer in the factory laboratory. First add montmorillonite to the sewage, and then add anionic polyacrylamide. The total amount of montmorillonite added to the sewage is 60ppm, and the anionic polypropylene The total amount of amides added to sewage is 3ppm. Observe the size of the flocs and the sinking speed under stirring conditions, and measure the turbidity of the treated water at the same time. The measurement results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com