Method for preparing partial stabilization zirconium oxide ceramic capable of increasing thermal shock resistance

A technology for stabilizing zirconia and thermal shock resistance, which is applied in the field of partially stabilized zirconia ceramics, can solve the problems of uneven phase distribution of PSZ ceramics, limited ion diffusion of stabilizers, and unsatisfactory thermal shock resistance of materials. Uniform phase distribution, improved thermal shock resistance, and stable composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Weigh 3mol% of Y 2 o 3 and ZrO 2 Powder, mixed oxides are obtained after ball milling;

[0019] (2) Add 5wt% polyvinyl alcohol solution as an adhesive to the mixed oxide powder, the weight ratio of the adhesive to the oxide powder is 1:12, and stir evenly;

[0020] (3) The material is pressed into tablets by 13t mechanical pressure, pre-fired at 600°C, and kept for 3 hours;

[0021] (4) The pre-fired sample is ground through a planetary mill, and the obtained ZrO 2 -Y 2 o 3 Powder, the maximum particle size is 18μm;

[0022] (5) The powder was mechanically pressed and sintered in an air atmosphere at 1600°C to prepare Y 2 o 3 -PSZ ceramics.

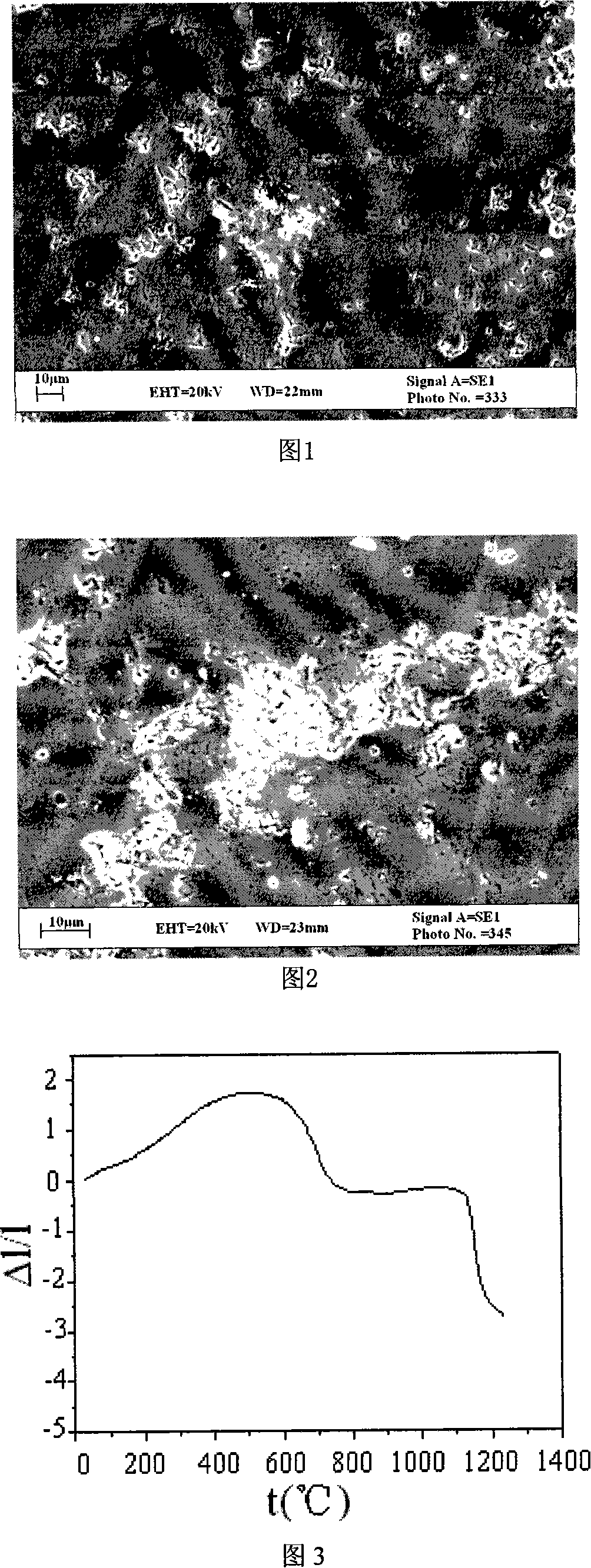

[0023] Synthetic Y 2 o 3 - The tetragonal phase is evenly distributed in the PSZ ceramic matrix. Y mixed with oxide powder and pre-fired 2 o 3 -Compared with PSZ ceramics, the PSZ tetragonal phase prepared by the method of the present invention is fine and the degree of uniform distribution is obviously improved. ...

example 2

[0025] (1) Weigh 7mol% of MgO and ZrO 2 Powder, mixed by ball milling;

[0026] (2) Add 8wt% polyvinyl alcohol solution as an adhesive to the mixed oxide powder, the weight ratio of the adhesive to the oxide powder is 1:10, and stir evenly;

[0027] (3) The material is pressed into tablets by 10 tons of mechanical pressure, and the flakes are pre-fired at 820°C and kept warm for 2 hours;

[0028] (4) The pre-fired sample is ground by a planetary mill, and the maximum particle size of the synthesized powder is 17 μm;

[0029] (5) ZrO will be obtained 2 -MgO powder was mechanically pressed into blocks and sintered in an air atmosphere at 1680°C to prepare MgO-PSZ ceramics.

[0030] Compared with the co-precipitation method, the content of the stabilizer is basically constant during the operation of the method of the present invention, the phase composition of MgO-PSZ is controlled within the set range, and has a higher monoclinic phase, a lower cubic phase and a certain tetra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com